From machine supplier to service provider – 100 years of HAVER & BOECKER Machinery Division

What began as a company in Hohenlimburg producing wire mesh for miner‘s lamps led, among other things, to the founding of the machine factory in 1925, which over the course of a century developed into a leading global supplier of packing and filling technologies for the cement, building materials, and chemicals and food industries.

With the Rotopacker, SEAL technology, and Adams technology, the company has shaped key developments in modern bag packing. Today, digital systems, AI-supported production monitoring and inspection, and new service models are setting the next milestone for the future.

In this interview, Florian Festge, Managing Partner, Frank Ormeloh, General Manager, and Mirko Hoffmann, Head of Sales, explain how the machine factory has transformed itself from the manufacturer of the first Haver valve bag packing machine to a high-tech system provider – and why services, sustainability, and artificial intelligence will become just as important in the future as robust steel constructions.

Frank Ormeloh: With cement as a building material. In the beginning, cement was filled into simple jute bags – comparable to today‘s potato sacks. After filling, these bags were closed manually with a so-called wire loop, which we supplied. This was simple, but in the long run neither efficient nor clean. And so the market pushed us towards automation.

Mirko Hoffmann: In the course of this, our location shifted. Westphalia – Oelde, Geseke, Erwitte, Beckum – was the center of the cement industry. So we moved the machine factory there. Oelde offered everything: skilled workers, transport connections, and above all, proximity to customers. In 1925, the HAVER & BOECKER machine factory was finally established here.

Frank Ormeloh: After the move, we began to build the first semi-automatic bag packing machines. But the requirements increased rapidly. Single-spout machines became two-, three-, and later four-spout systems. The operator had to work faster and faster, constantly attaching and detaching bags—at some point, this was no longer humanly possible.

The solution was a radical approach: we let the spouts rotate. The carousel principle was born—the Rotopacker.

Mirko Hoffmann: This created a new level of performance. Today, a modern 16-spout system produces filled bags every second. Everything is fully automated, from bag feeding to filling and venting to loading. The operator only monitors the process.

And: “Rotopacker” became an industry term. Even where it doesn‘t say Haver & Boecker on it, people say “Rotopacker.”

Frank Ormeloh: With increasing performance requirements – from 500 to today‘s 6,000 bags per hour – the rotating nozzles for filling bags were developed. This means that it is not the operator who walks around the machine, but the machine that walks around the operator. The carousel principle was a real quantum leap.

Frank Ormeloh: Two developments in particular stand out:

1. SEAL technology

Due to their design, valve bags lose product residues. This is unsanitary and a problem in retail. With SEAL, the valve bag was given an additional valve spout that is welded using ultrasound – clean, safe, and significantly more marketable. Many customers gained new market share as a result.

2. Adams technology

A completely different principle: a waterproof plastic bag that is formed, welded, and compacted using vibration technology. The development was created with Lafarge UK—due to the humid climate, weather-resistant, highly stable packaging was needed there in particular.

Mirko Hoffmann: The tubular-film bag makes it possible to store cement outdoors. It is also attractive as a marketing space – an argument that should not be underestimated for DIY store products.

Frank Ormeloh: Product protection is crucial: worldwide, up to 13% of the cement produced is lost due to moisture, spillage and dust. This causes enormous CO₂ costs, because because the production of cement is energy-intensive. With sealed tubular-film bags, we can massively reduce these losses. In addition, paper bags usually also contain plastic liners – but they are much more difficult to recycle than a single-type plastic bag. This can be recycled as a single-type plastic and reused in the same place.

Mirko Hoffmann: For high-quality products such as mortar, the proportion of Adams packaging is already around 50%. The quality advantage is convincing. And here, of course, the financial losses are much greater if the product gets wet.

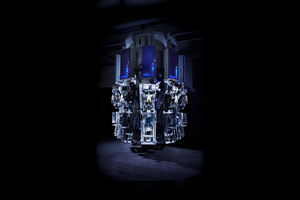

Frank Ormeloh: Enormously in recent years—not least because of COVID-19. With our QUATRO product family, we have permanent production and batch logging, remote maintenance and remote commissioning, data analysis for maintenance and wear detection, and AI-supported image analysis.

For example, the AI recognizes whether the correct bag type has been inserted, whether the valve is open correctly, whether the bag is damaged in any place, or whether the valve has been closed properly after filling.

Mirko Hoffmann: Defective bags are sorted out fully automatically. This saves cleaning effort, improves quality, and increases line availability.

Florian Festge: Instead of just supplying machines, we support the systems throughout their entire life cycle. This starts with location and product analyses, continues with engineering and testing in the bag laboratory, and extends to operational support or complete system operation, qualification of local workers, modernization of older machines, and spare parts and process consulting.

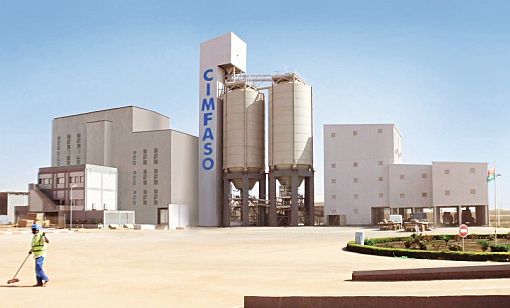

Frank Ormeloh: In countries such as India, Burkina Faso, and Ivory Coast, we operate complete packing plants, train teams, and ensure stable performance—qualified personnel are often in short supply there.

Florian Festge: Strategically, we will evolve from a machine supplier to a service provider – similar to how copiers are operated today in a usage model. The customer then does not buy a machine, but rather, for example, a guaranteed number of bags or available production capacities or complete process packages ...

Frank Ormeloh: Technologically, the focus is on higher performance, more AI, and more automation. We are testing robots that take on monotonous tasks, such as filling bag magazines or cleaning machines.

Florian Festge: The operator of the future will no longer be a “bag filler,” but a process conductor. The machine adapts to the product, not the other way around.

Florian Festge: A clear ownership structure. Two family lines, two votes – and both must agree. This prevents dilution and creates stability.

And the people. Our workforce is loyal, committed, and often has been with us for decades. We are not only a family business—there is also a family feeling here.

Frank Ormeloh: We recently had 45 participants in an internal training course—hardly anyone had been with the company for less than ten years. That says it all.