Future-proof through sustainability

When it comes to the sustainable digital transformation of the cement industry, a well-coordinated mix of electrification, hardware, and software solutions for both core production and secondary processes plays a crucial role. At the heart of this portfolio lies CEMAT – the process automation system for cement producers that ensures optimal plant performance. With its deep process expertise combined with standardized hardware and software, this integrated control system has been a reliable foundation for successful plant operations for over 50 years, constantly evolving to meet market demands. The fact that CEMAT is currently implemented in more than a thousand installations worldwide is a testament to its effectiveness.

Cement production is responsible for around 8% of global CO₂ emissions, making it one of the largest contributors to greenhouse gases worldwide. The majority of these emissions – roughly 60% – stem from the calcination of limestone, a process that inherently releases CO₂. The remaining 40% come from the high energy demands of rotary kilns, which are heated to extremely high temperatures using fossil fuels.

The cement industry is often referred to as one of the “hard-to-abate” sectors, meaning that reducing emissions is particularly difficult. While progress has been made with alternative green fuels, process-related emissions remain a significant challenge that cannot be fully addressed.

As a result, cement producers must perform a delicate balancing act – their plants must be cost-effective and deliver high performance, while also ensuring flexibility, energy efficiency, and maximum uptime. Additionally, the cement producers must comply with increasing environmental regulations and uphold the highest safety standards for people, machinery, and materials. The scale of the challenge is immense, yet it presents vast opportunities for sustainable innovation.

Highly desirable all-in-one solution based on the “digital first” principle

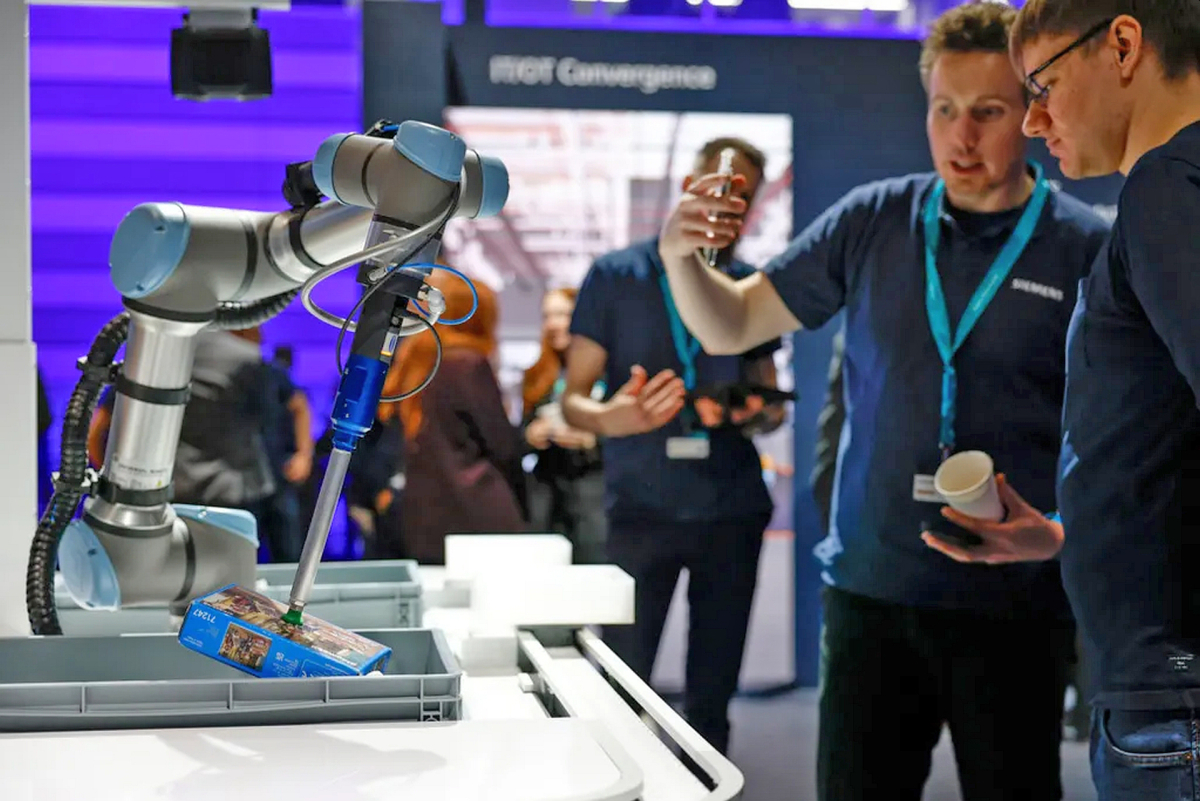

Given the numerous challenges confronting the industry, the solution is clear – a comprehensive portfolio of electrification, hardware, and software solutions that enhances both core production and secondary processes. The key principle driving this approach is “digital first”. “With Siemens Xcelerator, we offer our customers a simple, flexible, and open digital business platform that allows them to set up their digital enterprise more quickly and accelerate their transformation,” says Thomas Walther, Vertical Lead Minerals at Siemens Digital Industries. From his perspective, Siemens Xcelerator helps businesses manage the growing complexity of production processes, enabling faster progress across the entire product and production lifecycle. This opens up new possibilities for decarbonization, more efficient use of energy and resources, and advancements toward a circular economy.

“Other advantages include increased productivity, efficiency, optimization, and longer plant lifespans,” Walther adds. A prime example is integrated plant engineering, which ensures a seamless data flow, providing engineers from various disciplines with the precise information they need during the planning phase.

Additionally, a digital twin allows engineers to work within a unified system throughout each stage – from project planning to commissioning and maintenance – and conduct virtual 3D tours and training sessions before the plant is constructed. Optionally, a simulation project can be developed in SIMIT, Siemens’ simulation software. This means that many tests can be conducted in simulation mode during commissioning, significantly reducing the time needed for the project’s startup. Once the plant is operational, SIMIT can also be used to train staff and explore new ways to optimize plant performance.

In summary, cement producers gain a comprehensive view of the entire product and production lifecycle, as well as the broader supply chain ecosystem. This enables informed, data-driven decisions and enhances their ability to adapt to ever-changing market conditions.

Seamless automation integration from the field to the distributed control system

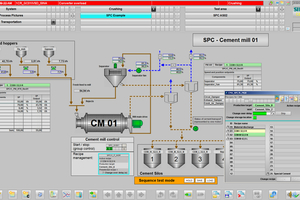

In the cement industry, ensuring a smooth and efficient production process is essential. This is where CEMAT comes into play – an integrated process control system specifically designed for the cement sector, managing every stage of production with precision. “CEMAT merges advanced process automation with digitalization and reliable, high-precision process instrumentation,” explains Walther. By providing complete transparency, this solution directly enhances the productivity and efficiency of cement plants.

For over 50 years, cement producers worldwide have trusted CEMAT – a flexible and innovative process control system that has continuously evolved. Over time, the hardware and software platforms have been upgraded, transitioning from the SIMATIC S5 to SIMATIC S7 programmable logic controllers to stay in line with technological advancements. Standard modules have been replaced and improved with each new version. This ongoing development ensures that while technological innovations are integrated, the core functions of the modules have remained consistent. From the outset, CEMAT was more than just a software library; it represented a broader philosophy. Today, the CEMAT library is a standard not only in the cement industry but also in mining and other sectors. As both a process control system and a library, it provides users and project developers with all the tools necessary for their tasks. System integrators and customers no longer need to create and maintain their own libraries but can instead leverage the standards of SIMATIC PCS 7 alongside CEMAT’s industry-specific functionalities.

One of CEMAT’s main advantages is its real-time transparency. All critical production data is instantly accessible, enabling operators to manage their plants efficiently and proactively. Additionally, the system enhances process quality and energy efficiency by offering data-backed recommendations for optimizations. CEMAT can even identify potential issues early, preventing costly problems before they arise.

A whole host of benefits thanks to edge computing

Edge computing is revolutionizing the cement industry by bringing computational capabilities directly to the production processes. Siemens is at the forefront of this transformation. Industrial Edge allows data to be processed in real time, right at the production site. This minimizes latency and enables immediate decision-making – a crucial advantage in the cement industry, where conditions can shift rapidly. By processing data on-site, cement plants can optimize their operations, enhance efficiency, and minimize downtime. The edge management system simplifies the central management of edge devices, applications, and data, providing essential tools for monitoring, updating, and maintaining the edge infrastructure.

Predictive maintenance

A key advantage of edge computing is its ability to enhance predictive maintenance. Siemens’ edge solutions process data from various sensors and devices in real time, predicting potential issues before they occur. This proactive approach not only reduces unexpected downtime but also prolongs the life of equipment, cuts costs, and enhances overall reliability.

Optimizing energy consumption

Energy efficiency is a critical concern in cement production. Siemens Industrial Edge supports companies in monitoring and optimizing energy consumption by offering comprehensive insights into energy usage patterns. By analyzing this data, cement producers can implement energy-saving strategies, reduce costs, and lessen their environmental impact.

Better quality control

Quality control is paramount in the cement industry. Siemens’ edge computing solutions provide continuous monitoring of production parameters, ensuring consistent product quality. Real-time data analysis allows producers to identify any anomalies and make necessary adjustments immediately, helping maintain high standards without delay.

Data assistant offers support wherever needed

As the number of maintenance technicians and control-room operators continues to decline, SIMATIC eaSie, Siemens’ data assistant, steps in to fill the gap. SIMATIC eaSie is a local support tool that delivers real-time data and status updates whenever needed, assisting with straightforward tasks such as routine maintenance and inspections.

Integrated into the existing SIMATIC PCS 7 and/or CEMAT systems, SIMATIC eaSie comes with an app compatible with smartphones and tablets. The app’s intuitive interface resembles those of popular messaging apps, making it easy to use. With the app, users can quickly access plant data such as process values (temperature, pressure, etc.), object statuses (operational, faulty, etc.), and diagnostic information. Interaction is simple, whether through chat, voice commands, or scanning barcodes/QR codes, and no specialized plant knowledge is required.

The app also allows for write actions, which are logged in the SIMATIC PCS 7 control system just like any other operator intervention.

Full lifecycle electrification of the plant

A reliable energy supply is the cornerstone of cement production, ensuring that electrical power is available whenever and wherever it’s needed. This requires precise planning, configuration, and control of energy systems to maintain a safe, dependable, and cost-effective energy flow throughout the entire lifecycle of the plant. “Our portfolio includes low-voltage and medium-voltage distribution systems, as well as solutions for monitoring, managing, and controlling energy,” says Walther.

SIMATIC PCS 7 PowerControl integrates process control and energy management into a single, unified system. By enabling seamless coordination between production processes and power distribution, this integrated approach enhances the overall performance of the plant.

With its combination of process control and energy supply management, the system optimizes energy usage and reduces operating costs. The predictive maintenance features analyze real-time data to anticipate potential outages, thus minimizing both downtime and maintenance expenses.

Integrated engineering, project management, and services

“Our customers value our extensive range of services, which are product-based, system-based, and application-based, covering the entire lifecycle of machinery and plants – from planning and development to operation and modernization,” explains Walther. This approach leads to reduced lifecycle costs while simultaneously improving performance.

The portfolio is further complemented by training, after-sales support, and maintenance services, ensuring sustained efficiency and operational reliability over the long term.

Driving sustainability and efficiency in the cement industry

A well-coordinated mix of electrification, hardware, and software solutions plays a crucial role in the sustainable digital transformation of the cement industry, impacting both core production and secondary processes – and in the future, this will also encompass carbon capture systems. Early feedback suggests that CEMAT is also ideally suited to carbon capture applications. This provides operators with additional advantages, such as an integrated operational and monitoring concept, along with streamlined spare parts and maintenance management. “At the heart of this solution is CEMAT – the process automation system developed specifically for cement producers, and one that we continue to enhance. For more than 50 years, it has ensured optimal plant performance, setting benchmarks for efficiency and reliability,” Walther concludes.