„Granulated blast furnace slag 2.0“ on basis of DRI slag - Results of tests in pilot scale

To achieve the European target of minimizing CO2 emissions by 2050, various steel companies have set themselves the task of replacing the CO2-intensive blast furnace with a combination of gas-based direct reduction and electrical smelting of the solid direct reduced iron. Together with a direct reduction plant, thyssenkrupp Steel Europe builds two smelters at its Duisburg/Germany site. Tests in pilot-scale demonstrate that water quenched smelter slag is glassy and has a significant own latent hydraulic reactivity. Therefore, it is a promising new supplementary cementitious material.

1 Background

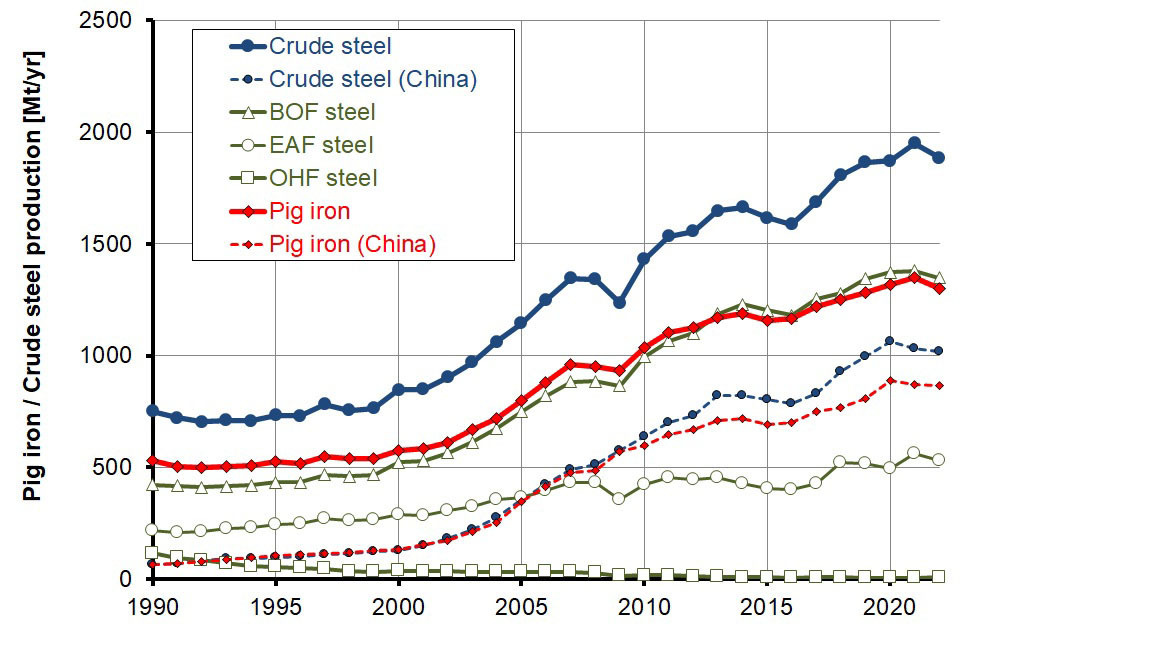

The steel and cement industries belong to the raw material-, energy-, and CO2-intensive sectors, each responsible for around 7 to 9% and 5 to 8% of global anthropogenic CO2 emissions. To achieve the European target of minimizing CO2 emissions by 2050, various steel companies have set themselves the task of replacing the CO2-intensive blast furnace process with a combination of gas-based direct reduction and electrical smelting of the solid DRI (Direct Reduced Iron) produced in the process [1,2,3]. With respect to the smelting process, this concept can be implemented in various units. Germany‘s largest steel producer, thyssenkrupp Steel Europe, has decided to build two smelters (sometimes called submerged arc furnaces or open bath furnaces) at its Duisburg site, in addition to a direct reduction plant with an annual capacity of around 2 million t [4,5,6]. The “electric pig iron” produced here will then be further processed into crude steel using the conventional BOF process.

The slag produced in the smelters is to be converted into glassy granules by water granulation, which - like traditional granulated blast furnace slag (GBS) - exhibits a latent hydraulic reaction. This would enable it to replace the granulated blast furnace slag that is inevitably lost due to the closure of blast furnaces. GBS is an established cement constituent for more than 140 years and thus replaces Portland cement clinker, the production of which is associated with considerable CO2 emissions, currently amounting to around 800 kg/t in Germany [7]. The market share of Portland slag and blast furnace cements was approximately 38% in 2024, whereas the share of Portland cement had fallen to an all-time low of only 20% [8]. The European cement industry aims to reduce the average clinker content in its cement portfolio to 60% by 2050, compared to 77% in 2021 [9]. A significant decline in GBS production without the steel industry providing an adequate substitute runs counter to this goal. Therefore, thyssenkrupp Steel has set itself the task of improving the smelter slag so that it can function as a substitute for GBS and thus for clinker.

The combination of a DRI plant and a smelter represents new technical territory in several respects. Since only one small DRI plant is currently operating in Europe, but this one operates in combination with an electric arc furnace and predominantly uses scrap, the scientific support for the construction of the industrial plant relies on laboratory and large-scale tests. Regarding the smelter slag, both were conducted as part of the „SAVE CO2“ project funded by the Federal Ministry of Education and Research [10,11,12].

This article is not intended to provide a comprehensive overview of the whole „SAVE CO2“ project, but rather focuses on the results of large-scale tests which took place in July 2024.

2 The pilot-scale tests

The series of large-scale tests was conducted in the test facility of a German ferrochromium plant using Submerged Arc Furnaces. The test furnace has a capacity of about 20 t. The energy input is realised by 3 electrodes (Figure 1). Based on different mixtures of DRI, pig iron ingots, granulated blast furnace slag, and other slag formers at least five tests were made resulting in different metal qualities and smelter slags. The raw material mixtures were adjusted in such a way that the resulting slags represent smelts consisting of different shares of DRI gangue (Table 1). The liquid slags were tapped into a ladle from which they were poured into a semi-industrial water granulation system (Figure 2 - Figure 4). After granulation the hardened slag granules were removed and stored on small heaps in order to drainage. All samples to be analysed were dried at 105 °C for 24 h. The subsamples for chemical analysis were dried only at 40 °C to detect theoretically present, easily evaporable components. All smelter slag samples were investigated regarding their chemical, mineralogical, physical, cementitious, and environmental properties. A granulated blast furnace slag from thyssenkrupp blast furnace No. 1 served as a reference.

3 The characterisation of the smelter slags

3.1 Optical appearance

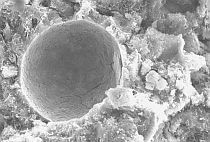

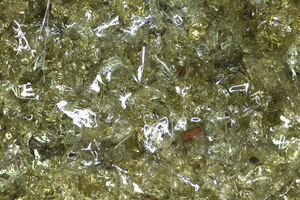

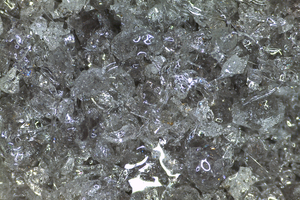

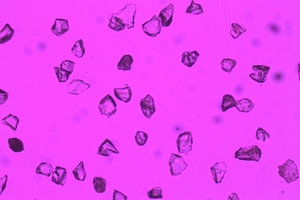

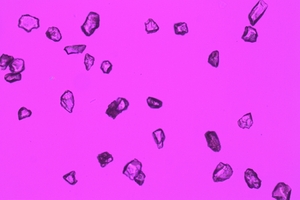

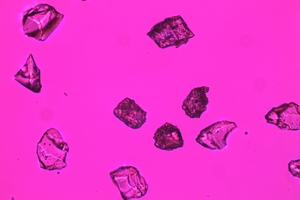

As examples Figure 5 shows the GBS being used as reference under a reflected-light microscope as well the smelter slags from tests No. 0 and No. 3. A striking feature of all DRI-containing samples is the significantly darker gray color compared to the GBS. But all smelter slags exhibited the typical glassy luster and a comparable grain size compared to GBS. As shown in Figure 6, most of all ground slag particles being used for the optical analysis of the glass content were transparent.

3.2 Physical properties

The physical properties of the granulated smelter slags did not show significant differences compared to typical GBS. The lower bulk density is explained by a coarser grading curve. The latter, in turn, is likely primarily due to the specific granulation plant configuration (geometry, water pressure and temperature, etc.). Furthermore, the viscosity of the liquid slag upon entering the granulation plant can also influence the grading curve. The viscosity, in turn, depends on the chemical composition of the slag, its tapping temperature, and the temperature loss during transfer of the slag ladle to the granulation facility.

3.3 Mineralogical analysis

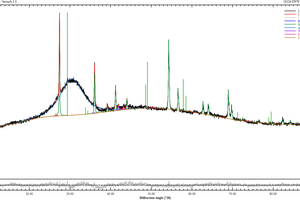

The glass content of GBS is important for its latent hydraulic reactivity. In a cementitious system with a high pH value only the glassy phase is corroded resulting in Calcium-Silicate-Hydrates formation whereas crystalline blast furnace slag of the same chemical composition is an inert material. The glass content of the smelter slags has been determined according as well by the transmitted light microscope counting method [13] as by quantitative XRD. The results are given in Table 2. All smelter slags showed a very high glass content of nearly 100 wt.-%. The requirement of the relevant standards EN 197-1 and EN 15167-1 is only “two third”. But it is well-known that most of the GBS currently produced worldwide has a significant higher glass content. As an example, Figure 7 shows the qXRD analysis for the smelter slag No. 3. The typical „glassy hump“ is very distinctive.

3.4 Chemical analysis

Beside the glass content the chemical composition of a GBS is the most relevant parameter for its reactivity. Regarding the main and minor components, the chemical analysis was carried out using XRF after fused tablet digestion. Some parameters were determined using other methods. The analysis of heavy metal contents and the eluate analyses were carried out using ICP-MS after full hydrofluoric acid digestion in the microwave. Chromium VI was determined using the method commonly used in the cement industry according to DIN EN 196-10. Organic parameters were not analyzed due to the thermal history of the slag.

The analysis results regarding the most relevant chemical parameters are listed in Table 3. All chemical requirements for granulated blast furnace slag defined in DIN EN 197-1 and DIN EN 15167-1 were met by the smelter slags, as planned (Table 4). Originally, the basicity of pure DRI slag would be very low. Thus, the viscosity of the liquid slag is too high and prevents a suitable slag handling, hinders the refining work of the slag and is a problem for the granulation process. Therefore, in any case the slag basicity has to be increased up to a minimum value. In addition, the basicity was further increased to guarantee a sufficient slag reactivity. It is a big advantage of the smelter technology that on principle any slag chemistry can be adjusted. Of course, the costs for correction materials and additional energy have to be considered.

The content of main and minor components in the granulated smelter slags largely corresponded to that of typical GBS (Figure 8). Compared to the reference GBS, they exhibited significantly higher Al2O3 and lower TiO2 contents, while having a significantly lower basicity. Furthermore, the smelter slags contained less sulfur which normally results from coke and coal as reduction agents in the blast furnace. The MnO contents were also below the already low values of GBS. While a lower basicity would suggest lower reactivity in cementitious systems, higher Al2O3 contents and lower TiO2 and MnO contents are positive in this regard.

Due to its chemical composition, in particular its high basicity, the reference GBS was very reactive, thus representing a challenging reference. For example, the results of the longtime GBS monitoring of FEhS organised for its member plants show a median value for the basicity (CaO+MgO)/SiO2 of only 1.31, instead of 1,54 for the reference GBS.

3.5 Environmental properties

On principle, building materials may impact the environment by the release of dangerous substances or radiation into soil and air. Due to the high temperature processes and the raw materials being used for smelter slags only the leaching of substances, in particular of heavy metals, might be a relevant topic. But due to the reducing atmosphere during the melting process already the content of heavy metals in the smelter slag is very low. Therefore, it could be expected that the leaching behavior as well of the slags themselves as of concretes made with them should be unproblematic. However, it must be mentioned that also significant higher contents of heavy metals in slags do not necessarily result in a high leaching! The binding of the heavy metal ions in different types of crystalline structures or in a glassy matrix have a strong impact on their release.

3.5.1 Heavy metals content

To evaluate the environmentally relevant aspects of substances that are not a standardised cement constituent or concrete aggregate, the German Institute for Building Technology (DIBt) often uses the solid and eluate limit values described in the Model Administrative Regulation Technical Building Regulations (MVV TB), Appendix 10 (ABuG) [14], even if these are only specified for industrial aggregates in water-contact concrete according to DIN 1045-2.

As expected, the heavy metals content of the smelter slags was very low. Table 5 shows only the data for parameters being limited. In contrary to the full digestion being used, the limit values are based on the analysis after a “softer” aqua regia extraction. It is obvious that all data fell below the limits by magnitudes. The only exception concerns Chromium for the smelter slag from test No. 0. The reason are the special pig iron ingots being used as part of the raw material mix. However, in practice only DRI and slag forming additives will be used.

3.5.2 Leaching of granulated smelter slags

according to DIN EN 12457-4

The leaching behavior of industrial by-products intended for use in cement and concrete is currently determined using the shaking method according to DIN EN 12457-4 (water/solid = 10:1, test grain size 0-10 mm). The results for the granulated smelter slags are shown in Table 6. It can be seen that the eluates from the smelter slags comfortably met all the requirements defined for different by-products, e.g. steel or copper slags. It is striking that the Al concentration in the eluate increased significantly up to test 3 with the maximum slag content from DRI of 70 wt.-%.

3.5.3 Leaching of granulated smelter slag according to DIN 19529

The elution process according to DIN 19529 (water/solid = 2:1) is enshrined in the German Substitute Building Materials Ordinance (EBV) [15] applicable to road and waterway construction. While the goal of “SAVE CO2” is to use the granulated smelter slag as a substitute for GBS and thus clinker in cement, its use as an aggregate in other construction purposes is also conceivable, as is the case with unground GBS, too. In particular, DIBt is striving to substitute the current leaching test by the EBV test according to DIN 19529. Since the MVV TB/ABuG cannot refer to a national procedure due to the notification requirement, the comparable European test procedure according to EN 16637-3 should be used (only up to w/s = 2), which leads to comparable results. However, based on several studies limit values are currently only specified for the scope of the EBV, but not for that of the DIBt. A simple conversion of the eluate concentrations obtained in both test methods is impossible because, for example, the significantly different water/solid ratios result in different pH values and concentration levels.

The results for the granulated smelter slags are shown in Table 7. It can be seen that no eluate value exceeded the few “material characteristics” defined for the different blast furnace slag (“HOS”) or GBS (“HS”) classes. In addition, also all requirements for steel slags (not shown on the table) have been fulfilled.

4 Cementitious properties

4.1 Cement preparation

To evaluate the cementitious properties of the granulated smelter slags, the ground slags were tested in a 50% combination with a Portland cement CEM I 42.5 R, which met the requirements for a test cement according to EN 15167-1. Secondly, 75 wt.-% of the slag were mixed with 25 wt.-% ground Portland cement clinker and a sulfate carrier. The sulfate content of these mixtures was 4.5 wt.-% SO3. Although the cement type CEM III/B (66-80 wt.-% GBS) has only a small market share in Germany, the high slag content helps to demonstrate the specific slag impact more clearly than is the case with the 50/50 combinations. These combinations were originally intended for quality control of ground GBS, not for assessing the reactivity of different GBS.

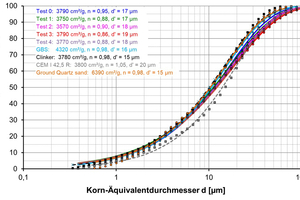

The slags were ground in a closed 10 kg batch ball mill to adjust the grain size distribution specified for the FEhS Institute‘s “GBS data base”. The grain size distributions of the ground slags and the belonging fineness parameters are shown in Figure 9. For comparison, the data for ground quartz sand (inert reference), a GBS from thyssenkrupp Steel Europe (reference), the clinker, and the Portland cement CEM I 42.5 R were also shown. Similar grain size distributions were achieved for all materials. The smelter slags were a little bit coarser compared to the reference GBS. The Portland cement was coarser, but of typical fineness.

4.2 Workability properties

The water demand and the setting times were tested according to EN 196-3. For all smelter slag containing cements the water demand was lower compared to the Portland cement (30.5 wt.-%). It was 25.5-26.0 wt.-% for the 50/50 combinations and 24.0-25.0 wt.-% for the 75/25 combinations, respectively, whereas for the GBS containing cements it was 27.5 wt.-% and 26.0 wt.-%, respectively. The mortar slump was tested according to EN 1015-3. With 225-240 mm it was higher for the smelter slag containing cements compared to the GBS containing cements (210 mm) and the Portland cement (202 mm). The initial setting time was comparable for the cements with smelter slags (3:29-3:50 h:min for 50/50 combinations and 3:25-4:10 h:min for 75/25 combinations) compared to the GBS containing cements (3:45 and 4:10, respectively) and lower compared to the Portland cement (3:15 h:min). All in all, the workability properties of the cements with granulated smelter slags are comparable to those with GBS and beneficial compared to Portland cement.

Whereas the chemical water demand of a cement mainly depends on clinker characteristics and clinker content, the physical water demand strongly depend on the particle size distribution and its slope (n). The water demand directly impacts the mortar slump. For the concrete workability additional parameters are relevant, e.g. cement content, water/cement ratio, aggregate properties. Depending on the grinding facility and the classifier adjustment n may vary. Lower values (< 1) are advantageous, higher values (> 1) are disadvantageous. Grinding in a closed ball mill normally results in a wider particle size distribution (n < 1), as shown in Figure 9.

4.3 Strength development

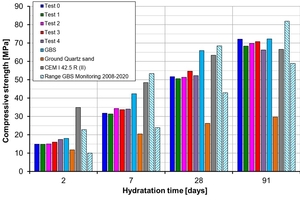

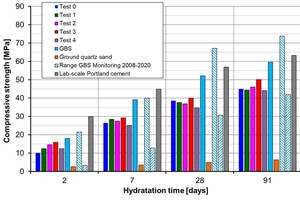

The strength development was tested according to EN 196-1. Figure 10 and Figure 11 show a significant active strength contribution from the granulated smelter slags even after a hydration period of only 2 d. Regarding the activity index (= relative strength) the minimum requirements of EN 15167-1 for 50/50 combinations (45% after 7 d, 70 % after 28 d) were considerably exceeded (65-71 % and 80-86 %, respectively).

In combinations with 50 wt.% Portland cement, the clinker reaction usually dominates after 2 d of hydration time, since GBS reacts more slowly due to the required glass corrosion process. Differences between different GBS usually have only a minor effect at this age. However, in the slag-rich combinations with 75 wt.% slag the positive influence of the higher Al2O3 content (see Table 3) on early strength was very pronounced. The reactivity of the smelter slag was significantly lower than that of the highly reactive reference GBS, and thus rather in the lower range of the FEhS Institute‘s GBS monitoring program. Only at an age of 91 d did the strengths of the cements with smelter slag, at least in the 50/50 combinations, equalize to the strength of the blast furnace cement with the reference GBS. In the 75/25 combinations, however, where different slag activities have a particularly pronounced effect, a significant difference in strength persisted even after 91 d.

The main reason for this is the significantly lower basicity of the smelter slag ((CaO+ MgO)/ SiO2 = 1.23-1.33) compared to the very high basicity (1.54) of the reference GBS (see Table 3). Only at the age of 2 d the higher Al2O3 contents of the smelter slags (14.9-19.3 wt.%) compared to the average Al2O3 content of the reference GBS (11.4 wt.%) compensated the negative influence of the low basicity. At this point, however, it should be pointed out again that blast furnace cements CEM III/B have only very little market relevance in Germany and that they are more used for special concrete technology applications.

As already mentioned, the use of DRI smelters offers the opportunity to adjust more or less any slag chemistry being intended. Therefore, a further increase of the basicity in excess of the metallurgical minimum in order to optimise the slag reactivity might be an option for the later industrial practice. In the past, also for blast furnaces this was practice in limited scale to compensate e.g. high and negative TiO2 contents.

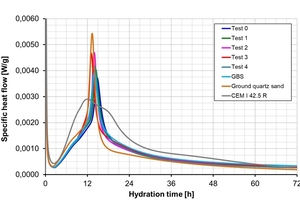

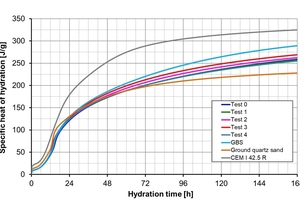

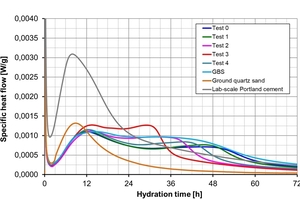

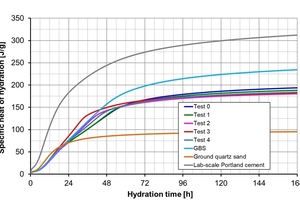

4.4 Heat of hydration

In addition to the strength tests, the heat of hydration development was determined by heat flow calorimetry according to DIN EN 196-11 for a period of 168 h. As expected, the heat of hydration development of all smelter slag-containing cements was significantly lower than that of Portland cement and lower than that of the GBS containing cements (Figure 12, Figure 13). This reflects the different strength developments. Naturally, the combinations with inert quartz sand powder showed the lowest heat development.

For the 50/50 combinations Figure 12 (upper graphic) shows that after a hydration time of approximately 14 h the ground quartz sand only led to an intensification of the clinker peak being relatively broad due to the sulfate. The increased availability of nucleation surfaces plays a role here. A similar, somewhat less pronounced effect is evident when using smelter slag. Between the various slags no differentiation is possible. Furthermore, a significantly higher heat flow than with the ground quartz sand is evident after a hydration time of approximately 18 h. After 168 h of hydration, all cements containing smelter slag showed very similar heat development, which was significantly lower than that of the Portland cement, lower than that of the cement containing the reference GBS, and higher than that of the cement containing inert quartz sand powder (lower graphic).

For the combinations with 75 wt.-% smelter slag (Figure 13), a greater differentiation of the various cements is possible. The clinker peak was no longer intensified in any of the cements; only the dilution effect is clearly visible after about 10 h. While no further heat peak occurred in the combination with ground quartz sand, this was clearly present in all combinations with smelter slag and GBS. It occurred earlier the higher the Al2O3 content of the slag was (upper graphic). However, this effect is limited to the first 72 h of the hydration time. After 168 hours of hydration, all cements with smelter slag showed very similar and low heat evolution, which was far below that of the Portland cement, significantly below that of the cement with the reference GBS, and significantly above that of the cement with quartz sand powder (lower graphic). Below 270 J/g, a cement exhibits a “low heat of hydration” (“LH”). This property is particularly advantageous for massive concrete constructions, as it leads, for example, to lower thermal stresses in the hardening concrete.

5 Outlook

The results being discussed above clearly show that granulated slag from the DRI + smelter route can be truly considered as “GBS 2.0”. As well technical as environmental requirements are fulfilled and the slags show a significant latent hydraulic reactivity. As known for GBS, the reactivity strongly depends on the same criteria, mainly chemical composition and glass content. Without any doubt the ongoing investigations of concretes made with smelter slag containing cements - organized by the project partner Heidelberg Materials - will confirm the suitability of granulated smelter slag as a supplementary cementitious material.

The start of the new combination of the DRI shaft furnace and the two smelters is currently expected for late 2027. At the same time a blast furnace will be closed and the availability of GBS will decrease. Therefore, it is necessary to prepare in time the frame conditions in order to be allowed to use the granulated smelter slag in cement and concrete. If a new cement constituent is intended to be used, in Germany a general technical approval (abZ) from the DIBt is required. Depending on the specific requirements of the application (combination with one or more clinkers, special properties of the new cements, exposure classes of the concretes, etc.) a more or less extensive test program has to be completed. After the general technical approval has been granted, cements produced with “GBS 2.0” can ideally be used in the same way as cements made with conventional GBS.

An approval procedure is also possible on the European level, regulated by the Construction Products Regulation. This must be initiated with the European Organization for Technical Assessment (EOTA) and one of the national Technical Assessment Bodies (TAB). In Germany, the responsible TAB body would be the DIBt.

In the long term, the inclusion of granulated smelter slag in European cement and concrete standards is certainly appropriate. Ideally, this would be achieved by expanding the existing list of permitted main and minor constituents. As a first step, a technical dossier must be submitted to the responsible CEN Committee TC 51 “Cement and Building Limes”, documenting all relevant information on cement and concrete properties. The structure of such a dossier is described in CEN/TR 16912 [16]. In addition, TC 51 will also evaluate the environmentally relevant properties of the new cement constituent and the cements produced with it.

From the today‘s point of view, it can be expected that in near future granulated smelter slag will be a relevant supplementary cementitious material with beneficial technical, environmental and economical properties.

Acknowledgement

The results described above were achieved within the research project “SAVE CO2” funded by the Federal Ministry for Education and Research (BMBF), grant no. 01LJ2004. The authors thank BMBF for the financial support.

![8 Position of the smelter slags compared to the blast furnace slags being registered for REACH [17]](/uploads/images/2025/w300_h200_x600_y337_Figure_8_Smelter_slags_0-4-2a1a5fc2596acd6d.jpeg)