Holcim, thyssenkrupp Uhde and TU Berlin test innovative process for CO2 capture

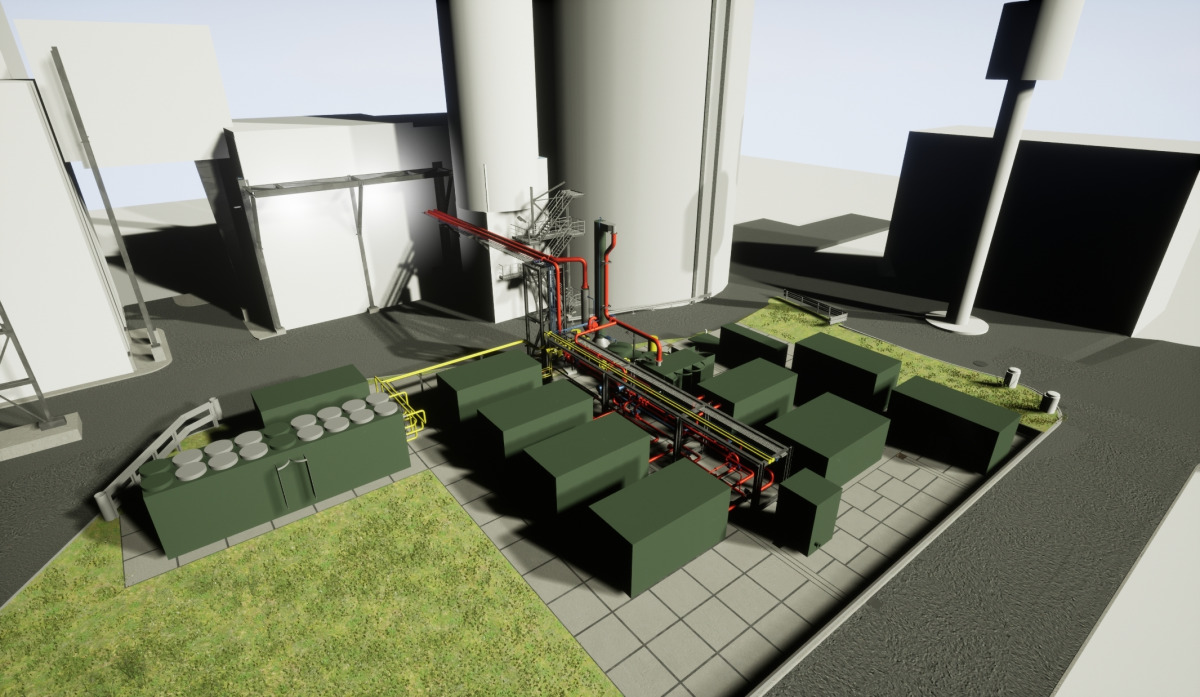

Just over a year ago, partners Holcim Germany, thyssenkrupp Uhde and the Technical University of Berlin announced their collaboration to research the use of the latest amine scrubbing technology to separate process waste gas CO2 at Holcim’s Beckum cement plant. The first test phase of the project started in May 2023 with the installation of a first plant module at the plant.

The aim is to significantly reduce CO2 emissions from existing cement plants and, at the same time, to make the captured CO2 usable for other applications in the future. Until the end of 2025, the partners will test the promising technology, which can make an important contribution to decarbonizing the cement industry in Germany, on a small scale. If the tests go as planned, the result after capture and processing will be high-purity CO2, which could then be sold as a feedstock to other industries or processed into other energy sources such as methanol.

During the test phase, continuous adjustments will be made and the test capacities will be expanded with the construction of a second plant module with new innovative processes. The performance and efficiency of these facilities will be tested with real waste gas at the Holcim cement plant in Beckum. With this process, the partners want to contribute to the reduction of climate gases, especially in existing cement production plants. The aim is to retrofit the plants with equipment to separate CO2 from the process exhaust gas without having to make any further adjustments to the production process. The project is funded by the German Federal Ministry of Economics and Climate Protection under the grant number 03EE5103A.