Innovative conveyor technology for high-performance bucket elevators

New design and lower weight: These are the advantages of the new central chains from RUD. The central chains are available in several sizes with an integrated or a separate mounting bracket. As a specialist in conveyor technology and with continuous innovation, RUD is expanding its product range for lower nominal sizes. The RUD central chains are suitable for use in high-performance bucket elevators in various industries including cement production.

“Our central chains have been manufactured since 1992, and now we have launched a new variant with a new design and lower weight. We have also extended the nominal sizes and offer the new central chains in two variants,” explains Anne Kühling, Head of Product Management Conveying & Driving at RUD Ketten Rieger & Dietz GmbH u. Co. KG.

Central chains for high-performance bucket elevators

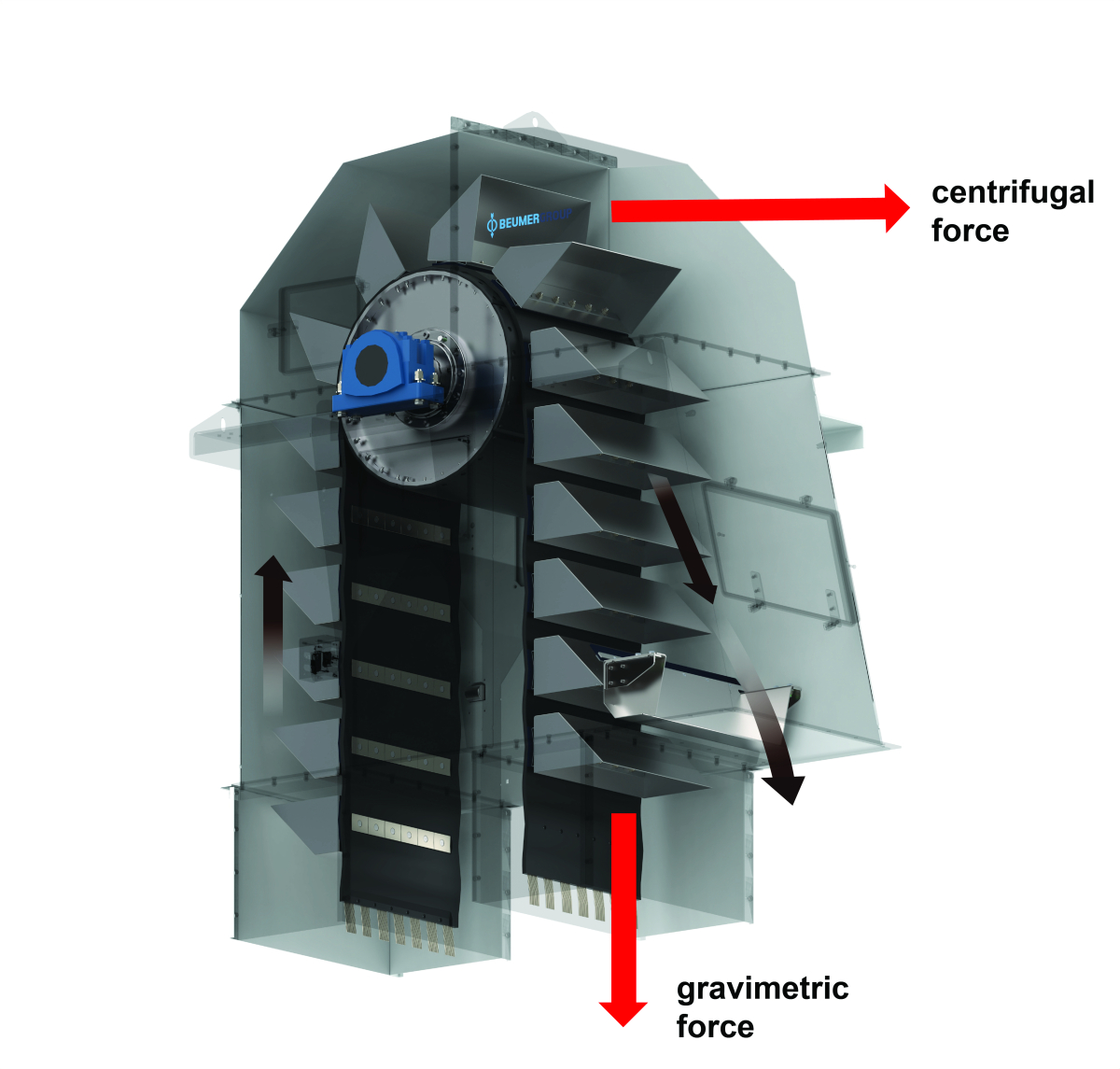

RUD’s central chains are used in high-performance bucket elevators in the conveyor industry. Bucket elevators convey cement, limestone, gravel, coal or even rock salt and soda, reliably and efficiently. RUD central chains are a robust means of traction for vertical conveying of powdery, granular, lumpy and high temperature materials.

New design with low weight

What‘s new about RUD’s central chains is the design and the technology behind them. Their system works in a similar way to a bicycle chain. RUD has completely updated its original process of rotating pins. The reason for this shift is due to the lower weight. The new generation of central chains is now significantly lighter. It works with less deadload and with better performance.

The market demand

The weight reduction of RUD’s central chains was a result of a worldwide survey done with RUD’s customers and sales partners. “The weight factor was raised by the majority of the respondents. We addressed this issue early enough during the development and hence we were able to design and optimise the chains accordingly,” explains Rupert Wesch, Head of Application Technology Conveying & Driving at RUD Ketten Rieger & Dietz GmbH u. Co. KG.

Efficient conversion

RUD central chains are designed in accordance with VDI 2324 and can be used for bucket elevators in the bulk materials industry. In addition to installing them in new systems, they can also be retrofitted on existing bucket elevators that have round link chains or belts.

Thanks to the expanded range, production and maintenance engineers can now get the most appropriate central chains for their bucket elevator systems. Existing round steel and belt bucket elevators can be converted into high-performance systems with RUD central chains. The big advantage of central chains over round link chains is that they can be run at a higher speed. Original equipment manufacturers also benefit from the RUD portfolio: New bucket elevators can be built narrower and with reduced costs.

Expanded range

RUD central chains are available in two variants, with a separate or an integrated mounting bracket.

The central chain with a separate fixing bracket is the RUD solution in size RU 100 which has a breaking force of 1000 kN, a weight of 45.2 kg/m and is suitable for bucket widths between 400 and 800 mm.

RUD also offers three chain sizes for the central chain with an integrated mounting bracket: RU 40, RU 55 and RU 70. The smallest variant (RU 40) has a breaking force of 400 kN and a weight of 20.3 kg/m. It is suitable for bucket widths between 200 and 400 mm. The RU 55 (breaking force 550 kN) and RU 70 (breaking force 700 kN) central chains are used for bucket widths between 250 and 240 mm and 300 and 630 mm respectively. “With this new innovation, we have focused on the lower nominal sizes,” emphasises Rupert Wesch.