Retrofitting ball mills for high-moisture supplementary cementitious materials: A sustainable path to lower CO2 emissions

The cement industry is actively working on reducing the environmental impacts of their processes while maintaining product quality and competitiveness. Supplementary cementitious materials (SCMs) such as slag and fly ash offer a solution to lower Scope 1 emissions and support circular economy principles given that embodied emissions are allocated to the main production processes from which they originate. However, their high moisture content and varying properties present technical challenges in some grinding processes. This article explores how retrofitting existing ball mills with tailored solutions enables efficient use of high-moisture SCMs. Drawing on a recent industrial case, it demonstrates how engineering adaptations optimize performance, and help cement producers meet sustainability and climate goals.

Introduction

Managing, reporting, and reducing CO₂ emissions is becoming increasingly essential as global regulations and carbon markets continue to evolve. Governments and international institutions are implementing stricter environmental requirements which demand greater transparency, consistency, and accuracy in how companies measure and disclose their greenhouse gas (GHG) emissions.

To support these efforts, the GHG Protocol provides a globally recognized framework for companies to account for both direct (Scope 1 and 2) and indirect (Scope 3) emissions throughout their value chains. In the cement industry, specialized tools aligned with the GHG Protocol help companies track and report emissions more accurately. Among these, the Cement CO₂ Protocol, originally developed by the Cement Sustainability Initiative (CSI) of the WBCSD [1] and now managed by the Global Cement and Concrete Association (GCCA), has become the most widely used standard for measuring CO₂ emissions in the cement industry.

A key element of the Cement CO₂ Protocol is how it addresses the use of mineral components that replace clinker or cement, particularly when these materials are by-products from other industrial processes. According to the protocol [1], the carbon dioxide emissions generated during the production of materials such as slag from steel manufacturing or fly ash from coal-fired power plants, which are commonly known as supplementary cementitious materials (SCMs), are not considered indirect emissions of the cement industry. Instead, these emissions are assigned to the primary industries that produce them, such as the steel or energy sectors. As a result, replacing part of the clinker in cement production with materials such as slag or fly ash, cement producers reduce their Scope 1 emissions while also supporting circular economy principles by repurposing industrial by-products.

SCMs earn the title due to their hydraulic activity, comparable with that of clinker, which allows direct replacement up to certain proportions without jeopardizing the final product quality. Materials such as the mentioned ground granulated blast slag (GGBFS) and fly ash may even enhance the properties of the final product, in addition to the environmental benefits. For instance, the use of GGBFS in concrete contributes to reduced heat of hydration, improved ductility, decreased concrete pore size, increased strength at later ages, and lower primary energy consumption [4], among other benefits.

In Figure 2, a comparison between the specific CO2 emissions of ordinary Portland cement (OPC) and two types of cements containing GGBFS at different proportions is shown. The proportion of slag is considered to have zero CO₂ emissions per ton of material, as these emissions are allocated to the steel industry. Therefore, the higher the share of slag in cement, the lower the share of clinker, and consequently the lower the specific CO₂ emissions per ton of cement produced. In this example, the CO₂ emissions decreased from 0.70 t CO₂/t cement for CEM I to 0.37 t CO₂/t cement for CEM VI/A-S, clearly demonstrating the decarbonization potential of clinker substitution.

Managing the technical challenges of SCMs for sustainable cement

While the use of supplementary cementitious materials is an effective strategy to produce more sustainable cement and improve the properties of the final product, it also poses several challenges, such as high moisture, grindability and variabilty among sources.

While the use of supplementary cementitious materials is an effective strategy to produce more sustainable cement and improve the properties of the final product, it also poses several challenges, such as high moisture, grindability and variabilty among sources.

One of the most significant is the high moisture content commonly found in many SCMs, not only because its complete drying is required for the cementitious products, but also because it may cause issues when processing the material with some grinding technologies. Ground granulated blast furnace slag, for instance, is a hydrophilic material that can easily retain up to 12% moisture, and fly ash is often found with over 20% moisture content when retrieved from ponds. The first assessment to be made when analysing the feasibility of grinding high moisture SCMs, either pure or mixed with other cement components, is whether the material will require a separate solution for pre-drying, which means a considerably higher investment, or if the drying can be achieved directly at the grinding equipment. For the latter to be feasible, a typical solution is using a hot gas source for the gaseous inlet required for the mill ventilation.

If the plant has an available waste gas source (originating from other processes within the cement plant) at a suitable temperature and volume flow that can be easily diverted to the mill inlet, this becomes the most sustainable path. Otherwise, the typical solution is to employ a fuel powered hot gas generator, although technologies to provide hot gasses using cleaner sources are being developed. It is important to note that the fuel-powered hot gas generator solution inevitably produces carbon emissions that must be included in the product’s carbon footprint as part of the Scope 1 emissions [1]. These CO2 emissions should be carefully considered when evaluating the material as a clinker substitute from both sustainability and carbon market perspectives.

Among the different grinding technologies available, the ball mill is the best suited for the sustainable grinding of high moisture material. This is due to the high conversion of power intake into heat that occurs mainly from the friction between the material and grinding media, causing the electrical power of the mill motor to strongly contribute as a heat source for the required drying and heating. Therefore, without requiring a hot gas source, the ball mill can already handle a higher inlet moisture of the feed material compared to its counterparts.

The amount of moisture that can be handled by the ball mill depends on the material’s grindability and the desired product fineness, which together define to the grinding power required to process one unit mass of material. The harder the material and the finer the product, the higher the specific grinding energy and, consequently, the heat input to perform the drying. While the mill throughput will be lower to achieve the required product, a higher moisture could be processed without the need for a complementary heat source. If the material inlet moisture is higher than this threshold, hot gasses are still required to provide the extra energy input, but less than for other grinding technologies under the same conditions. The inclusion of a drying chamber may also be required to partially dry the material before the grinding chambers, depending on the moisture content.

From theory to implementation - Retrofitting ball mills for SCMs

When designing a new ball mill, all key parameters are evaluated and incorporated to meet the customer’s required production rates under the given conditions. However, certain markets currently have an idle production capacity, meaning that there are installed mills not in operation that could be recommissioned for the grinding of pure SCMs, to be sold as a cementitious material or mixed with other cement components ground separately. This approach aligns with circular economy principles by extending the useful life of existing equipment, reducing the need for new manufacturing, and minimizing the use of raw materials. Reusing and repurposing mills also supports sustainable industry practices by lowering embodied carbon and promoting resource efficiency within the cement production process. In this case, all the mentioned conditions of moisture, product fineness, material grindability, etc. must be evaluated under the existing mill layout to check for the feasibility of its use for the new purpose. In the best-case scenario, only smaller adaptations such as a revision of the ball charge profile will be necessary, but as the moisture content increases, investments such as the installation of a hot gas generator and partially converting the mill layout to include a drying chamber may be required and must be carefully evaluated.

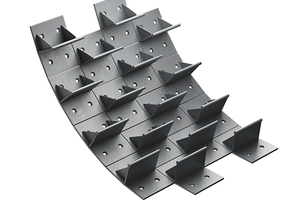

In a recent case in Spain, a known cement producer has partnered with Christian Pfeiffer to adapt an existing double chamber cement mill for grinding wet GGBFS containing up to 10% moisture. While the typically high grindability of slag and product fineness requirement would already enable the mill to process a moisture content of about 2,5% without requiring thermal energy input, the high moisture content of the slag to be ground in this case required not only the use of a hot gas generator, which was already existing in the grinding circuit, but also that part of the mill length was converted into a drying chamber. This was done by replacing the existing liners and intermediate diaphragm with specially designed Christian Pfeiffer’s drying chamber elements (Figure 4 and 5) followed by the open lifter diaphragm, designed to allow the material to freely pass from the drying to the grinding compartment and ensure a smooth flow of the mill ventilation at a low pressure drop.

For such conversions, the total mill capacity decreases, as some of the previously available grinding length is converted into a drying chamber which provides no grinding effect. To define the necessary length of the drying chamber and allow the mill to keep the highest possible grinding volume after the conversion, a full assessment of the expected operation and mill design must be done.

While detailed heat balances of the full circuit and of the drying chamber as an isolated section are calculated to ensure the best match between hot gas volume flow, mill outlet temperatures and drying rate at the drying chamber for a given length, it is also essential to evaluate the mill shell design and the types and position of chamber elements such as the current bolting profile of the existing liners and position of the manhole. If a modification of the mill shell is necessary, such as drilling the shell to add more bolts, Christian Pfeiffer can perform a finite element analysis to evaluate if the proposed modification is safe, or if the shell could be at a risk of fracturing, in which case another solution must be found to address the issue.

It must also be evaluated whether the grinding should remain with two separate grinding chambers and an intermediate diaphragm, or if it can be executed with a monochamber mill. As the available grinding volume is already decreased due to the partial conversion into a drying chamber, a monochamber layout is favoured to avoid losing more grinding area with another diaphragm. Due to the typical fine granulated particles of raw GGBFS, it is normally a suitable material for monochamber grinding.

After a thorough assessment of all relevant variables, the final internal layout for the mill to ensure optimal grinding conditions was defined by Christian Pfeiffer engineers, that also calculated the required thermal power for the operation. In this case, the installed power of the existing hot gas generator was sufficient to provide the additional energy needed for drying the high-moisture raw GGBFS, eliminating the need for its replacement.

Foreign Matter Trap - Enhancing mill performance and durability

In addition to the new mill internals, a Foreign Matter Trap was supplied to remove scrap materials from the circuit and help maintain the equipment’s integrity and operational efficiency (Figure 6). This is especially important for materials such as slag, which normally have a high contamination of metal scrap that can strongly interfere with the process efficiency.

While the FMT plays an essential role in purging the unwanted particles, the accumulation of scrap material, together with the high abrasiveness of GGBFS require special attention. The mill must be regularly inspected for filling degree and diaphragm slot cleanliness, since grinding media top up and slot cleaning are expected to become more frequent when grinding pure slag. It is also recommended for mills with high utilization to make a yearly sorting of the full grinding media to replace worn out media, scrap material and update the grinding media profile, thus keeping an optimized equipment performance.

After the delivery of the new components, the assembly was meticulously supervised by an expert from Christian Pfeiffer. The startup and process optimization were also carried out in close collaboration with a Christian Pfeiffer engineer, and the system performed according to the projected parameters.

Conclusion

Using supplementary cementitious materials like slag is key to reducing CO₂ emissions and supporting the circular economy in cement production. Retrofitting existing ball mills to grind high-moisture SCMs extends equipment life and promotes sustainability. With Christian Pfeiffer’s careful engineering assessments tailored to the material’s properties and customer requirements, cement producers can address moisture and grindability challenges without sacrificing throughput or quality.

The successful collaboration between Christian Pfeiffer and cement manufacturers exemplifies how innovative solutions and expert guidance can accelerate the industry’s transition to greener products, reinforcing commitments to climate targets and environmental stewardship.