Spectraflow receives a new order for one airslide analyzer from St. Marys Cement (Votorantim Group) Bowmanville/Canada

St Mary’s Cement, part of the globally acting Votorantim Cement Group ordered the first SpectraFlow Airslide Analyzer for raw mill optimization for their Bowmanville Cement manufacturing unit in Canada. This is the 1st SpectraFlow Airslide Analyzer installation in the Votorantim Group and the 1st SpectraFlow installation in Canada. With this order SpectraFlow expands its installed base to 30 countries on all continents.

About Votorantim Cement Group

Votorantim Cement Group is the 7th largest company worldwide according to their current cement production capacity with 57.3 million t. The group is present in 11 countries including Brazil, Canada, USA, Bolivia, Argentina, Uruguay, Spain, Morocco, Tunesia and Turkey with a net revenue of nearly € 4.4 billion.

In 2001 Votorantim entered the Canadian market with the purchase of the historical St. Marys Cement at that time owned by Blue Circle. St. Marys Cement began operation in 1912 with a cement manufacturing unit in St. Marys, Ontario/Canada, while today St. Marys Cement operates 6 cement plants: 3 in Canada (St. Marys, Bowmanville, McInnis) and 3 in the USA (Detroit, Charlevoix, Badger). Within this service area, products are rigorously tested to meet the high standards demanded by today’s dynamic construction needs starting from the clinker production. SpectraFlow will play a key role in improved raw mix design to achieve highest clinker quality, stabilize kiln operation and reduce energy consumption.

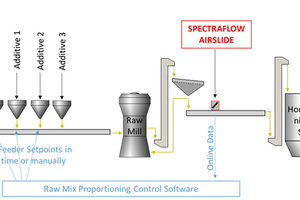

SpectraFlow will replace the existing XRF Atline system, which was installed to increase the sampling frequency and therefore the control actions on the additive weight feeders. Bowmanville plant operates a 450 t/h raw mill and standard hourly samples are to slow to efficiently adjusting the additive weight feeders as a single hourly sample represents 450 t of raw material. The Atline system increased the sample frequency to 10 minutes (6 samples/h), however as Atline systems have no proper sample preparation, the accuracy of the 10-minute results are low and therefore effective feeder adjustments based on the Atline results are not possible. Additionally Atline systems demand very high maintenance and down-times are common. SpectraFlow will overcome these challenges, as the online analyzer will increase the result frequency to every one-minute (60 results/h) and will massively improve the accuracy of the results as no sample taking or preparation is required. The raw mill will be continuously measured and the results can directly be transferred to the installed QCX software to adjust the additive weight feeders.

SpectraFlow Airslide Analyzer vs.

AtlineAnalyzer for Raw Mill

Optimization

The SpectraFlow Airslide Analyzer is installed on the airslide after the raw mill same as the sampling point. The Atline Analyzer is installed close to the sampling point and fed by a sample collected over 10 minutes and then directly measured. As the sample is not properly prepared (milling) as in a standard laboratory, the sample tablet has low representativity and therefore results are highly variable and not efficiently usable for weight feeder adjustments.

SpectraFlow Installation

for Raw Mill Optimization

The SpectraFlow Airslide Analyzer is an online analyzer to be able to measure raw materials in airslides. As raw materials are processed through a crusher and raw mill these are statistically homogeneous and therefore the analytical results of the SpectraFlow Airslide Analyzer are highly accurate.

By using a SpectraFlow Airslide Analyzer and a site-specific raw mix proportioning strategy the variation in the local raw materials can be balanced out to increase consistency of the raw meal and therefore kiln feed quality considerably. Also a variable MgO, Na2O, K2O, Cl and SO3 content is optimally monitored. The highly consistent kiln feed results in fewer kiln stoppages, refractory problems and simultaneously increase the clinker production.

Summarized benefits are:

The analyzer is free of any radio-active sources, neutron generators or any hazardous components. This means the SpectraFlow Analyzer does not require any permits or licenses regarding importation, operation or maintenance.

The SpectraFlow Analyzer is completely safe, maintenance can be done by the plant personal.

Raw meal quality will be homo-geneous and on setpoint. That results in stable and optimized kiln operation.

The Airslide Analyzer eliminates the need of automatic sample transport systems, automatic laboratories, high availability of operators and maintenance personal for controlling the raw mill operation.

This SpectraFlow order is the 64th order for the Cement Industry and the 1st Airslide Analyzer installation in Canada. SpectraFlow has an installed base worldwide of 90 analyzers (50 Crossbelt & 40 Airslide) in 30 countries across all continents.