The Góraż d że modernization project -

a remarkable project in many respects

Polish cement manufacturer Heidelberg Materials Poland relied on the technical expertise and technology of thyssenkrupp Polysius to solve problems with its rotary kilns at its Górażdże plant. This modernization order was the largest single order to date for the thyssenkrupp Polysius Service Team in terms of value - and this one was for kiln lines from a third-party supplier.

Introduction

Heidelberg Materials Poland operates a cement plant in Górażdże near Opole in south-western Poland. Górażdże is Heidelberg Materials’ largest and most modern cement plant in Europe. Kiln line 1 was modernized in 2003 to increase its clinker capacity. The modernization of kiln line 2 in 2011 further increased the plant‘s clinker capacity.

The plant noted recurring technical problems with the kiln bearings on both rotary kilns, which eventually led to production stoppages. Repairs, the replacement of parts, the readjustment of the roller bearings and process changes did not bring the desired success. The plant operator was already discussing measures which, in addition to replacing the equipment, would have included the construction of new foundations and would have meant a shutdown of at least one kiln line for several months

Course of the project

Heidelberg Materials approached the thyssenkrupp Polysius Service Team with this problem. In the first step, the thyssenkrupp Polysius experts carried out static calculations of the current situation at the third-party system using the technical documentation provided and an on-site measurement. Based on these results, system sketches and current process data, the appropriate solution was then designed, presented and finally installed.

Root cause

The calculation results of the current situation showed that the kiln bearing pressure, particularly at the inlet side and middle station, did not match the design criteria of thyssenkrupp Polysius and the current capacity utilization of the plant. The use of new kiln bearings was examined.

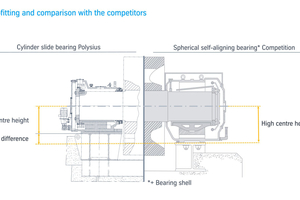

The kiln bearings from thyssenkrupp Polysius are characterized, among other things, by a low centre height, i.e. the distance between the bearing contact surface and the center of the supporting roller. The low height is due to the fact that the bearing housings are designed without the use of a spherical cap to support and self-align the roller axis. This aspect allows the use of individual adapter plates, which are mounted on the existing base plates. This has the decisive advantage that the foundations do not have to be structurally altered.

The base plates are first measured so that the individual adapter plates can be designed and manufactured. Once these adapter plates have been fitted, the respective inclination is checked and, if necessary, milled to the target dimension. This ensures that the inclination of the bearing matches the kiln axis and prevents misalignment. This procedure is also used when the base plate in the foundation settles over the years.

In order to model the two kiln stations and, in particular, to realize the connection to the existing base plate, the thyssenkrupp Polysius Field Service Team also carried out a 3D scan of the components.

Project delivery

The modernization offer comprised 16 new kiln bearings including adapter plates as well as two new kiln tyre shell section with loose fastening system for the kiln inlet side station. The operator Heidelberg Materials was so impressed by thyssenkrupp Polysius’ technical solutions that it was awarded the contract to supply the planned components for stations 2 & 3 of both kiln lines in January 2023.

“The modernization was strategically scheduled to coincide with the winter maintenance shutdown and was carried out under challenging conditions and significant time pressure. Nevertheless, our plant’s technical department - in close collaboration with the selected assembly contractor - maintained continuous contact with the thyssenkrupp Polysius headquarter in Beckum, ensuring that every aspect of the project was executed to the highest technical standards,” says Wojciech Kłyż, Maintenance Manager at Heidelberg Materials Górażdże

“The order for the Górazdze cement plant was remarkable in many respects,” says Olaf Köster, Head of Service Sales Europe. “It was the largest single order for thyssenkrupp Polysius service to date in terms of value - and this for two kiln lines from a third-party supplier.”

Another highlight was the production of the rollers and axles. With a diameter of 3200 mm and a weight of 82 t, these rollers were the largest ever machined in the thyssenkrupp Polysius workshop in Beckum/Germany. Together with the shaft, each unit had a total weight of 120 tons.

Heidelberg Materials’ satisfaction with thyssenkrupp Polysius’ performance was demonstrated, among other things, by the fact that the thyssenkrupp Polysius Service Team was awarded a multi-year service contract for the polscan® kiln measurement service after completion of the modernization project. thyssenkrupp Polysius provides service solutions along the entire life cycle of a plant - from inspection and maintenance to the supply of innovative spare parts and modernizations.