Thermoteknix unveils enhanced temperature monitoring platform at IEEE

MultiView Enterprise, the latest technology innovation from Thermoteknix Systems Ltd., developed for cement plants, is the first integrated sensor platform to deliver operators and plant managers the ultimate display and control solution for temperature monitoring and measurement across their clinker manufacturing process.

For more than 40 years, Thermoteknix has been developing ground-breaking infrared (IR) and thermal temperature measurement and monitoring solutions critical to the cement manufacturing process, ensuring consistent quality, efficiency and prolonged lifespan of plant equipment.

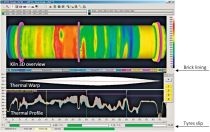

Thermoteknix MultiView Enterprise features a simple user interface that provides seamless live imagery and operation of multiple temperature sensors inside and outside the rotary kiln, cooler and crusher. MultiView Enterprise is Windows 11 compatible and ready to be installed to streamline clinker manufacturing process.

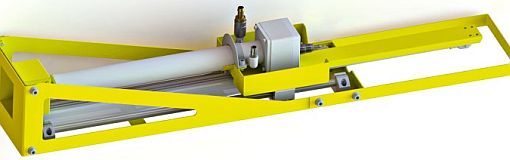

Thermoteknix Centurion Kiln Shell Scanners and ThermaScope HD Cameras for burner, cooler and crusher zones integrate with the MultiView Enterprise software platform to provide a complete view of the manufacturing process and precise temperature measurement and control.

Designed with flexible configuration, MultiView Enterprise allows for customisation and scalability, enabling plants to add more scanners and cameras providing future expansion as plant requirements change.

“We have customers who have introduced MultiView Enterprise to their operation to display live data from a single camera/sensor in the burner, and then extended their configuration, adding additional cameras to the cooler and crusher zones to expand their monitoring capabilities. Integration through OPC and hardware interfaces extend monitoring and real-time data access and control. Our priority has always been to deliver a solution that offers flexibility and can be customised to meet the specific requirements of the plant,” explains Dr. Richard Salisbury, Managing Director of Thermoteknix.

The typical benefits a user can expect to achieve from using MultiView Enterprise for cement are increased output, lower fuel consumption, longer refractory life and better and more consistent quality.

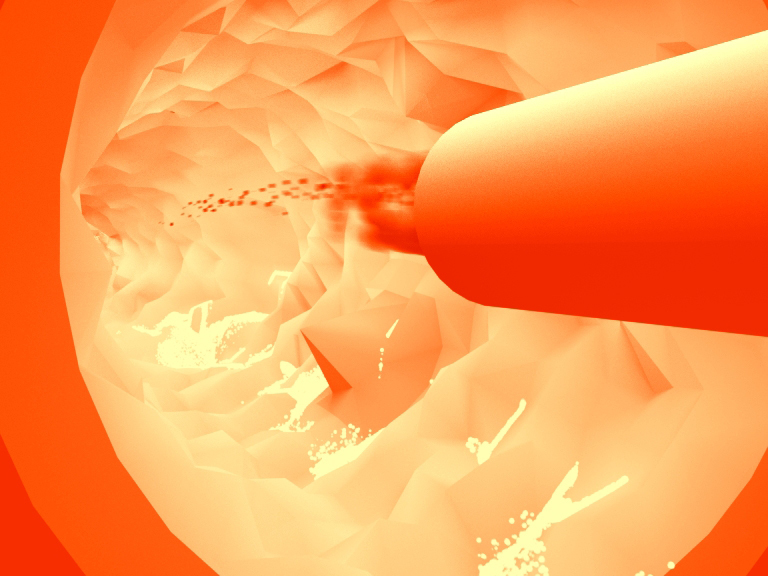

Real-time temperature monitoring enables adjustments to burner settings, fuel inputs, and other process parameters to optimise efficiency and product quality while minimising environmental impacts. Early detection of hot spots, ring formations, and other issues can prevent costly shutdowns and damage to the kiln shell. Accurate temperature measurement also allows for more precise control of the combustion process, leading to reduced fuel consumption and better regulation of combustion gases.

MultiView Enterprise enables plant operators to easily view simultaneously or switch between scanner imagery and burner/cooler cameras, so they can analyse high-definition imagery and measurements at every point of the process. Every pixel on the live video images can be selected for precise measurement of temperature both current and historical as well as real-time alarms to warn of pre-set limits.

A single continuous timeline links all sensors/cameras, tracking every event and change with the ability to pause, rewind, analyse and replay an event. More informed decision making avoids unnecessary and unplanned stoppages, extending the life of the kiln and reducing operating costs. Detecting potential hazards like hot spots or fires, allows for timely intervention.

Alarms can also be set that link to temperature changes or events, helping to limit sudden refractory failures and prevent and limit secondary damage to the kiln shell from light-up to shut down. Alarms can be linked to relays, audible alerts, on-screen messages and email to prompt immediate or appropriate action.

Thermoteknix is committed to supporting the cement industry as it addresses increasing demands from environmental regulation and the challenges of incorporating variable and alternative fuels. Optimising temperature settings can improve energy efficiency, reduce fuel consumption, and maximise throughput.

Plants already using MultiView Enterprise have reported significant improvement in optimising efficiency and reducing energy waste.

Thermoteknix is renowned for its innovation and ground-breaking advancements in thermal imaging solutions for the harshest of environments. The company has been honoured with 5 Royal Awards celebrating its innovative technology and global business success.