thyssenkrupp Polysius and SaltX initiate collaboration to develop emission-free production facilities

thyssenkrupp Polysius and SaltX have signed a Letter of Intent (LOI) to jointly develop the next generation of fully electrified production facilities. This partnership aims to scale innovative technologies and advance the decarbonization of the industry.

New technologies, fresh ideas, and exciting opportunities were the focus of a workshop between thyssenkrupp Polysius and SaltX, an innovative start-up from Sweden driving the electrification of calciners. Together, they discussed potential collaborations and the integration of this groundbreaking concept into various business areas.

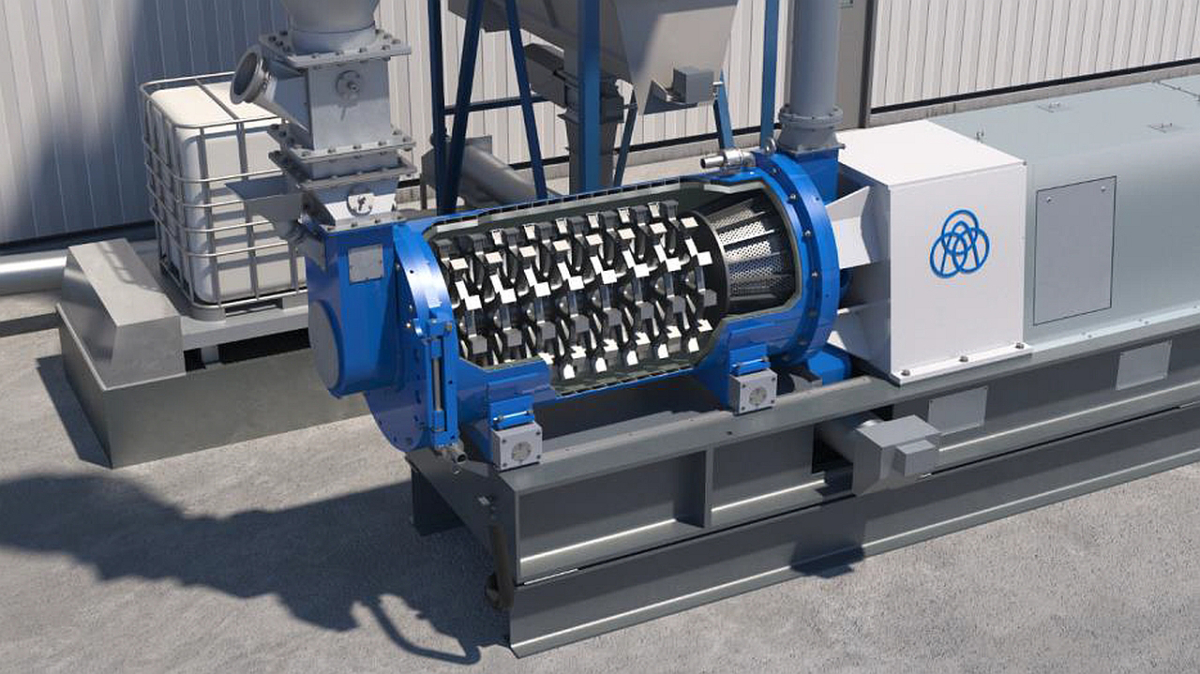

As part of this collaboration, SaltX’s patented Electric Arc Calciner (EAC) technology will be integrated into thyssenkrupp Polysius’ green system solutions. The EAC process enables the electric calcination of materials, replaces fossil fuels with renewable energy, and isolates the released carbon dioxide, resulting in an emission-free production process.

Dr Luc Rudowski, Head of Innovation at thyssenkrupp Polysius, stated: “The partnership with SaltX is a significant step towards a sustainable industry. By integrating the Electric Arc Calciner technology, we can expand our portfolio of green solutions and offer our customers innovative and environmentally friendly production methods. This collaboration is an important milestone on the path to decarbonizing the cement and lime industry.”

The electrification of calciners could be a game-changing technology for both thyssenkrupp Polysius and the entire industry. There is great potential in the areas of cement, lime, and DAC (Direct-Air-Capture). Cement is a key sector where sustainable technologies are becoming increasingly important. In the lime sector, electrification could bring new efficiency and environmental benefits. DAC is an innovative process for capturing CO2 directly from the ambient air.

Lina Jorheden, CEO of SaltX, added: “The collaboration with thyssenkrupp Polysius is of great importance to effectively implement our technology and drastically reduce CO2 emissions in the industry. Together, we can set new standards and offer our customers fully electrified and emission-free production facilities.”

Lukas Schoeneck, Head of Green Solutions at thyssenkrupp Polysius, commented: “This partnership is based on mutual trust and shared goals. Both sides benefit from the collaboration by combining our strengths and developing innovative solutions that are both ecologically and economically advantageous.”

The discussions with SaltX were promising, and the partnership agreement has already been detailed. This cooperation opens up new markets, more diversification, and the opportunity to further invest in a sustainable future.