World-first project to create net zero cement and lime cluster in the Peak District

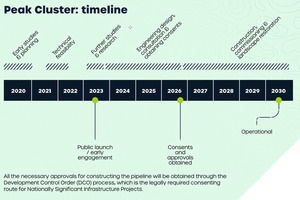

A world-first project has been launched to create a net zero future for the cement and lime industry. Located in the Peak District, the project will prevent over 3 million t of carbon dioxide emissions each year by 2030.

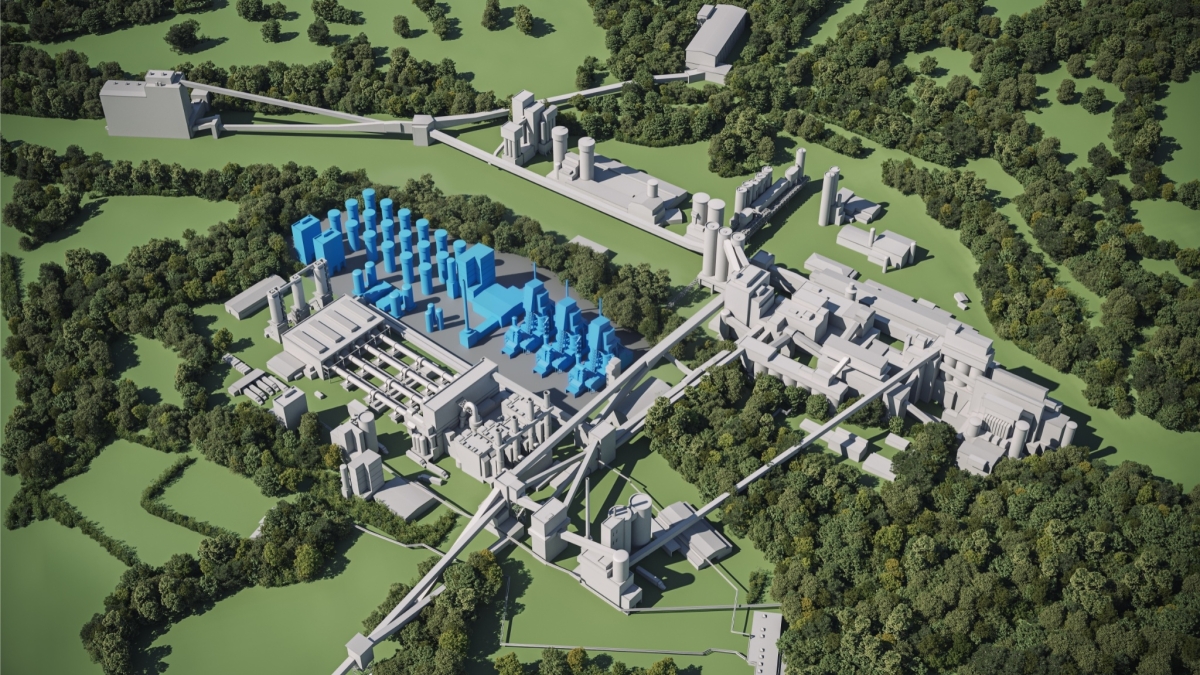

The project, named Peak Cluster has been initiated by five cement and lime plants in the Peak District and Staffordshire Moorlands, owned by Tarmac, Breedon, Lhoist and Aggregate Industries, together with the Lostock Sustainable Energy Plant in Cheshire.

Carbon dioxide emitted from the cement and concrete industry accounts for around a quarter of the total emissions in Derbyshire and Staffordshire. With 40% of all UK cement and lime manufactured in the Peak District and local area, the project has the potential to dramatically reduce the sector’s emissions to ensure the sustainable, net zero future of this essential industry.

Led by Progressive Energy, Peak Cluster aims to capture and transport carbon dioxide emissions from industrial plants in Derbyshire, Staffordshire and Cheshire before permanently locking away the carbon dioxide beneath the eastern Irish Sea in carbon storage facilities like the Liverpool Bay CCS or the recently announced MNZ Cluster.

John Egan of Progressive Energy, Peak Cluster Project Director, said: “Peak Cluster will make a crucial contribution towards the UK’s drive to net zero, making a serious impact on local, regional and national climate change targets. The project will help industry to continue to thrive into the future – safeguarding jobs, maintaining a booming supply chain and allowing current and future generations to continue to work in, and enjoy, this beautiful region.”

Dr Diana Casey of the Mineral Products Association, Director Energy and Climate Change, said: “The launch of the Peak Cluster is an exciting and vital step forward in the journey of the cement and lime sectors towards net zero. The region is a historic heartland for cement and lime production providing highly skilled jobs for local communities, and a secure supply of essential materials to the UK economy. The ‘UK Concrete and Cement Industry Roadmap to Beyond Net Zero’ highlighted the importance of carbon capture for the decarbonisation of the cement and concrete supply chain and the Peak Cluster is an essential part of that transition. This launch demonstrates the commitment of cement and lime producers to transition to net zero to secure the future of these important industries, and the vital products they produce, in a net zero world.”

The cement and lime sector is a key part of a combined mineral products industry, which contributes around £ 18 billion to the UK’s GDP and directly employs 81000 people, supporting a further 3.5 million jobs.