Expert Optimizer increases Nordkalk’s production by 9 %

Expert Optimizer was installed on the lime kiln at Nordkalk Corporation’s Lohja plant in November 2006; secondary commissioning took place in July 2007. Now ABB announced the production increase figures achieved by their Expert Optimizer solution Lohja plant in Finland.

Nordkalk is a leading producer of high quality limestone-based products in Northern Europe. The products are used mainly in the paper, steel and building material industries as well as in environmental protection and agriculture. At Lohja, ABB Finland is responsible for the maintenance of the factory by means of a full service contract and they agreed with Nordkalk’s initiative to buy Expert Optimizer as a method for improving the process.

The primary challenge to overcome for this project was that the coal mill had to be stopped at least twice every day. When the mill is stopped, and for a period after the mill restarts, it is not possible to get sufficient coal to the kiln. As the residence time of material in the kiln is about six hours, the kiln was never operating in stable conditions. A procedure for operating the kiln when the coal mill was stopped and being restarted was developed by pooling the extensive experience of Nordkalk’s operators and the ABB process experts. This procedure prevents the kiln from cooling too much and also reduces CO (carbon monoxide) generation.

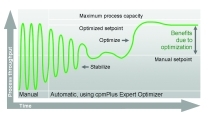

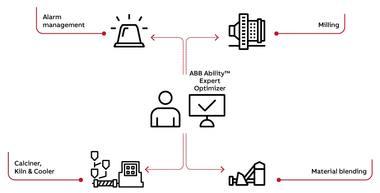

Expert Optimizer, part of ABB’s cpmPlus suite of solutions, ensures that the kiln is operated under optimum conditions according to the customer’s goals. At Lohja, the system always tries to increase production whenever kiln conditions allow. Finding the optimum operating point was difficult for the operators, as there are several sources of feed material, each with different properties. Expert Optimizer finds the best operating conditions to maximize output and minimize fuel consumption for each feed stone.

Even before secondary commissioning, Expert Optimizer made an impact with the production rate of the kiln increasing by more than 5 %. This improvement easily exceeds the guaranteed figures. Now, two years later, the production increase stands at 9 % and shows how the customer has received particular value from collaboration with different ABB units, in this case, ABB Switzerland’s Collaborative Production Management and ABB Finland’s

Performance Services.