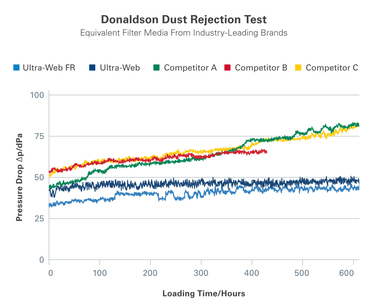

Change in dust collection technology

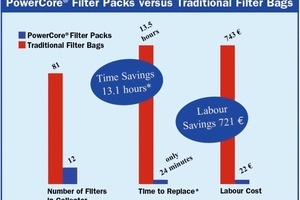

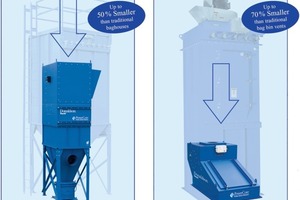

The development of PowerCore® fulfils the requirements for an easy and service-friendly maintenance of dust collectors, which has been a demand of the industry for many years: With the incomparably easy filter replacement and the extreme downsizing of the system, the Donaldson engineers have set the standard for an advanced dust collection technology. For a dust collection unit, which up to now had to be equipped with 81 bag filters each of 2.40 m in length, now only 12 PowerCore® filter packs are required (Fig. 1). These savings are based on a single filter changeover. In the calculation...