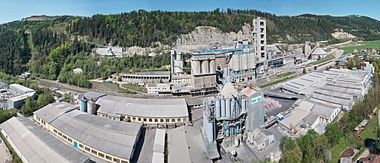

Kiln 2 at Robilante experiences

its second youth

Kiln 2 at the Robilante (Cuneo/Italy) plant was started up again in the middle of October 2009 after several important modifications had been made to the preheater tower. The objectives of this three-year (2006–2009) project were as follows: a) Increase the capacity of the kiln by reducing the pressure drop in the gas system, b) Use more waste-derived fuels and at the same time improve gas retention in the precalciner and significantly reduce CO in the stack. These objectives were achieved by replacing and/or modifying all the tower cyclones, from the 1st-4th stage and by completely replacing the precalciner and increasing its volume. These upgrades allowed us to increase the production capacity of the kiln from 1800 t/d to 2200 t/d. In addition to the upgrades to the tower, the kiln’s electrofilter was also converted into a baghouse. The last step of this modernization project is to build a new 60-meter concrete stack with a diameter of 3.6 meters. Construction is currently underway and is expected to be completed by the spring.