Garadagh Cement ensures production uptime using online Condition Monitoring System (CMS)

Garadagh Cement OJSC (Fig. 1), established in 1999 by the Swiss Holcim Group, is the only cement and clinker manufacturing company in Azerbaijan. The company covoers the majority of domestic demand with its high-quality products, which meet both local and international standards. Garadagh Cement is running its condition monitoring program with the aid of German technology using online CMS from PRÜFTECHNIK. These online CMS are instruments that monitor the condion of machinery such as air compressors that are production critical and must run reliably.

An uninterrupted production process is a key factor for performance and for a plant’s success. Machines involved in a production process should work without interruption to guarantee 24/7 operations. Production critical machines are those machines directly involved in the production process and have to maintain its reliability to the production process. In order to objectively determine the condition of the machines, monitoring is performed with so-called data collectors – portable devices or fixed installed online Condition Monitoring Systems (CMS) – that perform measurements of defined parameters that reflect the real condition of machines and include data on the vibrational behavior of machines, but also can include temperature, rotational speed of machines, etc and also process parameters as required.

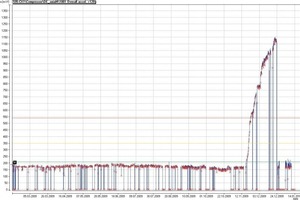

The online CMS at Garadagh Cement performs measurements and saves them on the OMNITREND® software platform that displays graphics in the form of measurement value trends, spectra, time wave form plots, etc. (Fig. 2). Trends of measured data and proper alarm settings enable very quick detection of problematic machines. In Figure 1 the trend of values recorded ith a vibration sensor (Fig. 3) clearly shows an increase of the vibration on an air compressor. Once an anomaly is detected on a machine, additional measurement data such as spectra are analyzed to find the root cause of the problem. After analysis, a diagnosis is done to define the root cause problem that is then eradicated.

Early detection in this case allowed a scheduled intervention which significantly reduced standstill costs, as there were no unexpected surprises. After the intervention the vibration

values in the trend decreased again to normal values. The VIBRONET® Signalmaster online CMS installed at Garadagh Cement uses special Current Line Drive (CLD) sensors designed in Germany, that transmit the measurement signal via current instead of the conventionally used voltage. This fact allows reliably using long cablings of up to 800 m as current signals will not be attenuated.

The advantages of an online system are quite simple. One of the most important advantages of an online CMS is that it does constantly collect data, allowing very close follow-up of machine condition on a daily or hourly basis which increases the reliability and therefore the availability of plant machinery. In case a measurement trend should increase, an online CMS would detect even a small variation from the start and would also notify a violation of measurement value limits – additionally sending alarms to PLC or SCADA if connected properly. For fast evolving failure trends, portable data collectors might not be the best choice as they are used to perform manual measurements at intervals, e.g. each 2–6 weeks on the same machine and measurement point. For such fast damage evolution cases an online CMS that reliably monitors the condition of the machine around the clock is a must.

One of the most remarkable advantages of online CMS is that these units can be accessed from any part of the world. Online CMS from PRÜFTECHNIK do have their own IP address which turns them into a simple network element that can be accessed via Internet by e. g. external vibration specialists. In addition, the German online CMS include a web server and an e-mail server that allows sending measurement data and alarms to the condition monitoring team or to any external partner. Telemonitoring and telediagnosis can be offered by specialists in Switzerland or Germany, firmware updates of the online CMS can be performed remotely and also new settings of the system can easily be adjusted as required from any remote location. This allows fast and professional intervention by specialist and technical support teams.

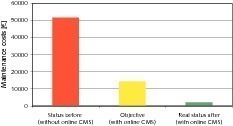

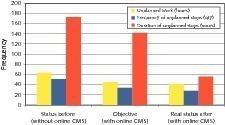

In 2008, the Holcim Group approved the reconstruction project of Garadagh Cement, and nowadays, the GARA6 Dry Kiln Project is being implemented, which will increase the production capacity and ensure the efficiency and high performance of the plant. The completion of the project and the launch of New Dry Kiln Line are planned for 2011. In view of the efficiency of the online CMS, the management of GARA6 Dry Kiln Project decided to start a completely new project for the installation of online CMS for the gear boxes of the cement tube mills. Garadagh Cement decided to use the online CMS as a modern tool to securely increase machine reliability to help secure production availability, but also to reduce the maintenance costs of monitored machines. In this case, the maintenance costs for the monitored machines and for a period of five months totalled 51 803 € (Fig. 4). The objective was to reduce these costs to 14 500 € – a reduction of a factor of 3.6! But the real sum required for maintenance costs then only reached 2134 € – an overall reduction of maintenance costs by a factor of 24.3! In other words: maintenance costs have been reduced to only 4 %, a great result. This clearly shows that the proper planning and implementation of a solid condition monitoring program as done by Garadagh Cement is a key factor to success. But also the quality of effectuated repair jobs, training of the plant’s maintenance team and a clear reporting and follow-up of actions allowed going beyond initial expectations. Another improvement has been achieved by also reducing the costs for unplanned stops for the monitored machines (Fig. 5); the frequency of unplanned works was decreased as well and also the duration of unplanned stops has decreased considerably – an overall successful project of Garadagh Cement.

Conclusion: The return on investment (ROI) for online CMS is usually achieved with the detection of a single problem, that unnoticed would normally cause considerable costs, unexpected production downtime including unnecessary machinery failures and repair times.