BHS-Sonthofen: bauma 2010 great success

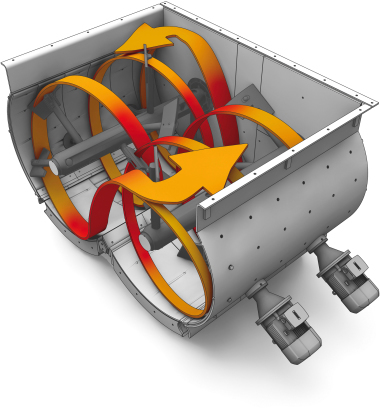

At the bauma 2010, which took place in Munich from 19.-25.04.2010, BHS-Sonthofen GmbH presented new products in the fields of mixing and crushing technology to their visitors and customers. Number one attraction and the highlight of this year‘s exhibition was the semi-mobile crushing plant BHS PROCRUSH. The compact and ready-to-use unit, featuring a feed hopper, inlet and discharge conveyor and a control system is well adapted for the use in changing requirements and locations due to its easy to transport dimensions and hydraulic support. Depending on the individual requirements the unit contains either the BHS Rotor Centrifu-

gal Crusher or the BHS Rotor Impact Mill. Displayed was also the new wear part generation for the VSI Rotor Centrifugal Crusher (e.g. anvil ring) and the Rotor Impact Mill (e.g. rotor protection). Through design optimizations, the lifetime of the crushing tools and wear parts will be significantly increased. By means of the new DKXN series, BHS-Sonthofen extends the successful product line of twin-shaft batch mixers (Fig.) by an optimized solution particularly for the production of high-slump ready-mix concrete. Furthermore, a twin-shaft batch mixer version with double mixing tools and a powerful drive system was presented from the DKX product line allowing much higher mixing speed and shear forces. In the area of mixing accessories, the impulse controlled central lubrication system was exhibited for the first time. The highly efficient lubrication technology will only be used once a day after the end of each production shift. The system supplies grease to the inner mixer through seals in a fully automated and reliable way.