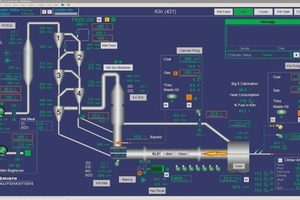

Dynamic simulation of alkali, sulphur and chloride circulation in a cement kiln

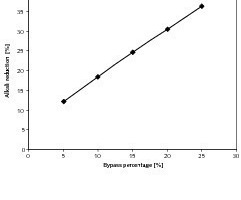

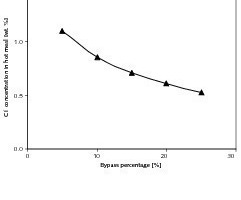

Summary: Training the operator to use the bypass in kiln operation is an important part of the whole training program, as the correct use of the bypass is critical to avoid operational problems caused by the internal circulation of alkali, sulphur and chloride in the kiln and to avoid unnecessary waste of energy. To facilitate the training for the correct use of the bypass by using dynamic process simulation, a new first-principle model is made to simulate the internal circulation of alkali, sulphur and chloride in the kiln. The model gives a good simulation of the internal circulation of alkali, sulphur and chloride in the kiln. The simulated results agree well with the theoretical expectations and practical observations.

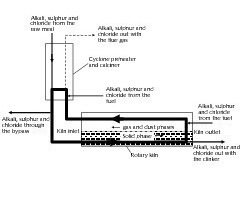

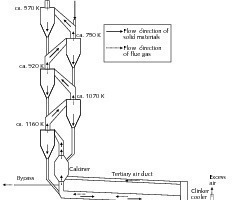

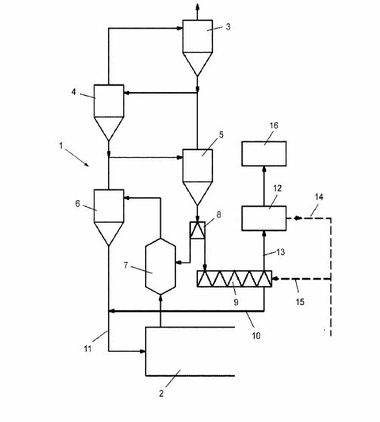

cement burning process

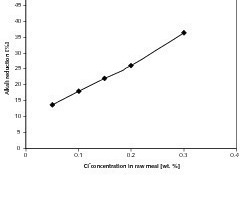

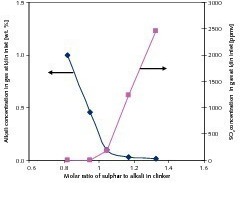

Alkalis (mainly sodium and potassium), sulphur and chloride are minor components in the raw materials used for clinker production. Depending on the sources of the raw materials, the concentrations of alkali and sulphur can be up to 1–2 %, while chloride can be up to around 0.3 %. The fuels used for clinker burning may also contain small amounts of alkali, sulphur and chloride depending on the fuel types. In spite of the relatively low concentrations of these substances, they have a great influence on clinker burning. The presence of...