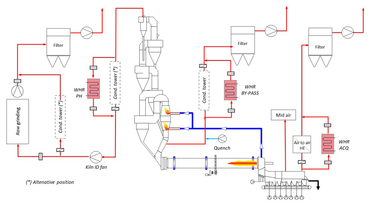

Waste heat recovery system in India

A waste heat recovery system delivered by FLSmidth to

Vicat Sagar Cements will be integrated with their new pyro line, which is also supplied by FLSmidth. The WHR system is expected to be operational by mid 2012. The 8.4 MW system is based upon steam Rankine cycle technology. Excess hot gases from the preheater and the cooler will be processed into usable power. At the same time the carbon footprint is reduced and water is saved.

www.flsmidth.com