A new ABB gas sampling system for kiln and calciner with a unique probe design

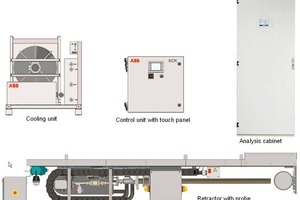

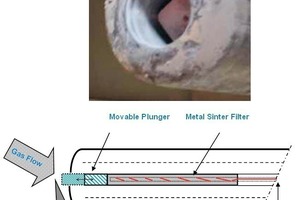

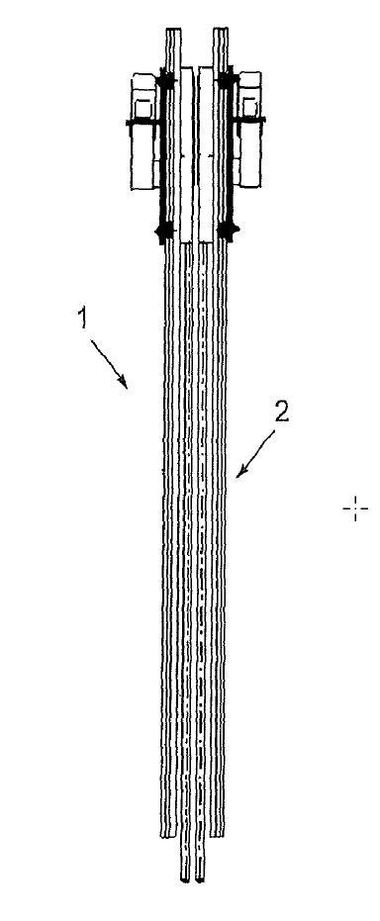

Summary: ABB has designed the new SCK system (FIg. 1) for the sampling of hot cement flue gas with a high dust load for gas analysis in harsh environmental conditions. Equipped with a unique probe, it allows the plant operator to save up to 3 days for maintenance every month due to an exclusive plunger design that mechanically breaks encrustations without interruption of sampling. At the end of 2009, the Cimpor Alhandra cement plant in Portugal updated a 10 year old sampling system with standard probe to a new ABB system with probe H and combined it with ABB’s gas analysis system ACX. The customer reports that maintenance is now reduced by 75 %.

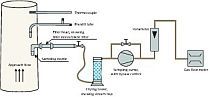

At the kiln gas outlet of a rotary kiln for the dry cement manufacturing process it is decisive for the plant operator to have continuous measurement of different measuring components such as CO, O2, NO ( and sometimes also SO2, CO2) for various process control purposes: for example to minimize fuel consumption, increase production, optimize combustion conditions at primary firing, improve clinker quality and reduce maintenance costs. At this measuring point the requirement is not only the right technology for the gas analysis, but also the suitable sample conditioning system....