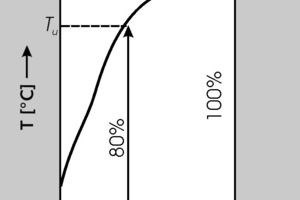

Extension of the wet slaking curve evaluation to include determination of the proportion of reaction-retarded material in the quicklime

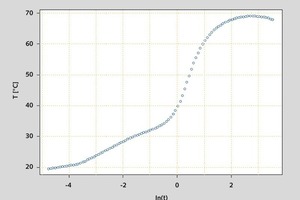

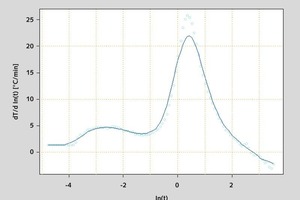

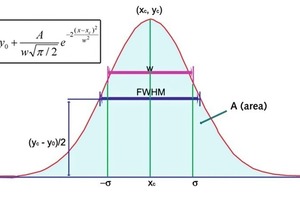

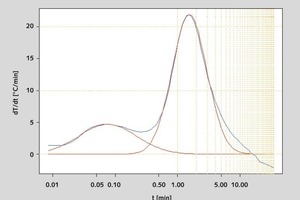

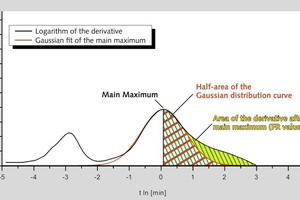

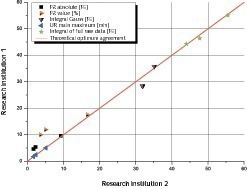

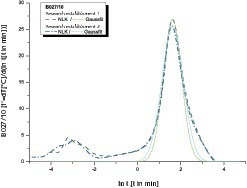

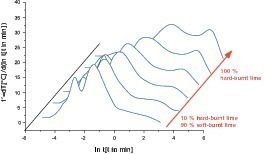

Summary: Determination of quicklime reactivity by the wet slaking curve has been extended to include not only a method for calculating the proportion of retarded final reaction material but also more precise determination of the reaction endpoint. Based on the hypothesis that in the ideal slaking reaction the derivative of the wet slaking curve follows a logarithmic Gaussian distribution curve and that any asymmetry in the final stage of the curve profile is attributable to material with retarded reactivity, mathematical rules were developed for calculating the derivative and fitting Gaussian distribution curves.

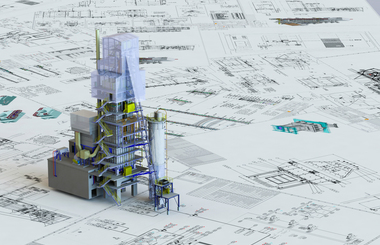

The present industrial applications of quicklime cover a large number of processes and areas of use. These entail a diversity of product requirements for the quality of the lime, e.g. with respect to the purity or homogeneity. Of particular importance is the reactivity of the quicklime produced so that the subsequent processes can be controlled reliably to achieve the required quality. Different applications sometimes require very different reactivities, but these must exhibit virtually no fluctuations. This means that determination of the quicklime reactivity is an important...

![2 K1: [t,T], raw data • K1 : [t,T], Rohdaten](https://www.zkg.de/imgs/tok_bbf34b50f5af3a37e4090cc577a9f147/w300_h200_x400_y283_101516696_d78a9d8ee7.jpg)

![3 K2: [ln(t),T], logarithmic abscissa in minutes • K2 : [ln(t),T], logarithmische Abszisse in Minuten](https://www.zkg.de/imgs/tok_0758989f655f4619224a0e8f7c552cf3/w300_h200_x400_y283_101516740_ca9439a690.jpg)