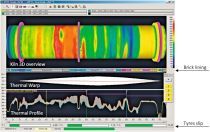

Thermal monitoring at E-Sheng Cement in China

The E-Sheng cement plant (Fig. 1) is situated 130 km South East of Chengdu, capital city of Sichuan Province. It is in an environmentally protected area and as such, it is subject to stringent regulations as far as pollution is concerned. The quarry is situated 5 km away on a hillside, 500 m above plant level. Transport of limestone is by one single conveyor.

The plant has 5 identical kilns, each 5500 tpd, i.e. 27 500 tpd total output, making it the largest single plant in the southwest of China. The plant was designed by the Nanjing Cement Institute (NCDRI). Its specific heat consumption is...