Validation system measures sustainability of products and technology

Sustainability plays a significant role in the long-term success of companies. Therefore, the BEUMER Group places importance on sustainability in their developments and is now evaluating the sustainability of every BEUMER product and every new development systematically, using a validation system. The user sees the results in black and white.

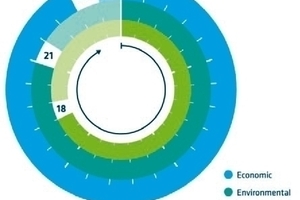

How high are operating costs? How high is energy consumption? How much material and which materials are being used, what are working conditions like for the machine operators? Questioning sustainability is becoming increasingly important to companies in order to be successful in the long term – especially now, with constantly increasing costs of energy and raw materials, as well as against the backdrop of the climate debate. The topic of sustainability poses a particular challenge for intralogistics. But, how sustainable is a system, machine or a drive unit really? To find a clear answer to these questions, BEUMER Group developed a validation system, the BEUMER Sustainability Index (BSI; Fig. 1), which BEUMER uses continuously and systematically to measure the sustainability of both new technologies and existing solutions.

Sustainability is measurable

“Our goal is to combine product performance and a sense of responsibility for man and the environment and thereby set a new standard for quality,” explains Dr. Christoph Beumer, Chairman and CEO of the BEUMER Group (Fig. 2). In order to achieve this, the company group obligated itself to evaluate its products comprehensively on three levels: economics, ecology and social responsibility. The BSI is a points system that records the sustainability of products with regard to these three levels. “Economic performance, market presence, financial chances and risks are known parameters. Our products will only become economically sustainable, when we tailor them and the corresponding production processes to long-term customer use,” says Dr. Beumer. Previously, the total cost of ownership (TCO) was the focus of business activities. Sustainability was defined solely from the ecological perspective. “For us, it is about incorporating ecological social aspects. Therefore, we follow a total value of ownership (TVO) approach. That means we see each product as a whole, not just the costs.”

Scarce resources must be used with care. All efforts must be directed at continuously reducing energy and resource consumption in the production cycle and in operating the machine. “Therefore, we need to reduce material consumption, waste and emissions to a minimum and optimise transport routes and packaging,” explains the CEO. Social responsibility is the third essential item BEUMER considers in its sustainability strategy. “Only when social factors such as health, working and product safety, employment and manufacturing conditions are in order, can we obtain a long-term and successful market presence. This relationship is mirrored in our products,” says Dr. Beumer. “We do not want the term sustainability to be seen as a trendy buzz word, but instead be seen in its inherent meaning: in equilibrium, in the balance between ecological demands, economic success and social responsibility.” In order to incorporate sustainability in the organisation and in processes, BEUMER applies the standards ISO 9001 Quality Management System, ISO 14001 Environment Management System, and OHSAS 18001 Work and Health Protection Management System. BEUMER unites and bundles these three standards.

Evaluation divided into five categories

To evaluate sustainability with the BSI, each of the three levels is divided into five categories. For example, this includes “Efficiency and Effectiveness”, “Service Life,” “Production-Related Resource Consumption” or “Training and Education Standards”. These categories are evaluated with up to five points. The sum results in a classification of „excellent, “very good”, or “needs improvement”. If a product is classified as needing improvement, BEUMER puts it through a re-engineering process, so that it can achieve a higher classification.

With a sustainability index of “excellent”, BEUMER offers the highest classification of sustainability in its newly developed, high-performance packaging system, the BEUMER stretch hood® i (Fig. 3). The economic value is based on a 30 % reduction in the compressed air used, low film consumption and a high throughput of 115 pallets per hour. The improved user interface design allows for ergonomic work, and the menu can be used simply and intuitively. For comparison: its predecessors, stretch hood S and M models, were capable of handling a minimum film thickness of 60 µm – the BEUMER stretch hood® i can handle film that is 40 µm thick. This flexibility significantly reduces consumption costs while helping to reduce environmental impact. Energy consumption is reduced by 12.5 % compared to the two previous models. This, along with the machine‘s energy consumption of 0.02 kilowatts per pallet, also significantly reduces operating costs and environmental impact.

Sustainability is the motto

Sustainability is not a fad for BEUMER, but a long-term issue and has always been part of the business thinking and activity. “Our objective is not short term profit, but long term success,” is BEUMER‘s motto. Therefore, BEUMER has invested heavily in its own company and done much for its employees from its inception. The company was founded by Bernhard Beumer in 1935 at the Beckum location. Family spirit, the integration of employees into all operational processes, innovation, communication and the constant dialogue between Sales, Engineering and Research and Development are the basis for this future-oriented alignment. Manageable growth, a large range of products and global market presence ensure our long-term success, Dr. Beumer explains.

For the company, sustainability also means promoting young talent. “It is the only way we can close gaps and equip ourselves for future challenges,” Dr. Beumer adds. “In order to achieve long-term, profitable growth as a family-owned enterprise, we need good employees, in whose training and education we can continue to invest. We plant the idea of sustainability with our trainees right at the start.” BEUMER will continue to do everything to promote the further development of sustainability in its products, services and its own company. “Always under the premise of satisfying our customers, employees and the environment,” stresses Dr. Beumer.

www.beumer.com