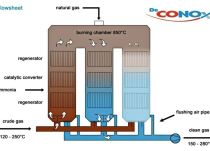

New SCR denitrification plant

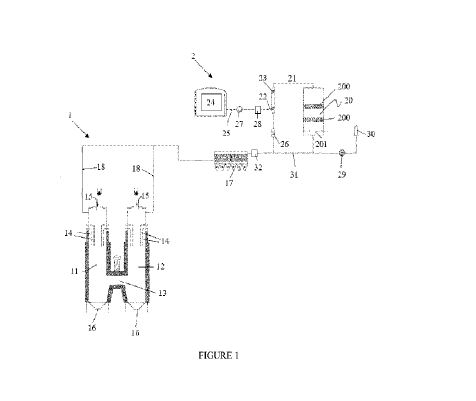

At the end of March 2011 a new denitrification (DeNOx) plant was put into operation at the location of German cement manufacturer Südbayer. Portland-Zementwerk (SPZ) Gebr. Wiesböck & Co. GmbH, in Rohrdorf. The new selective catalytic reduction (SCR) system converts nitrogen oxides (NOx) and ammonium hydroxide from the kiln exhaust gas into atmospheric nitrogen and water, thus reducing emissions considerably to meet not only current but also future emission regulations. The DeNOx plant is the first of its kind in operation at a cement plant worldwide (Fig.).

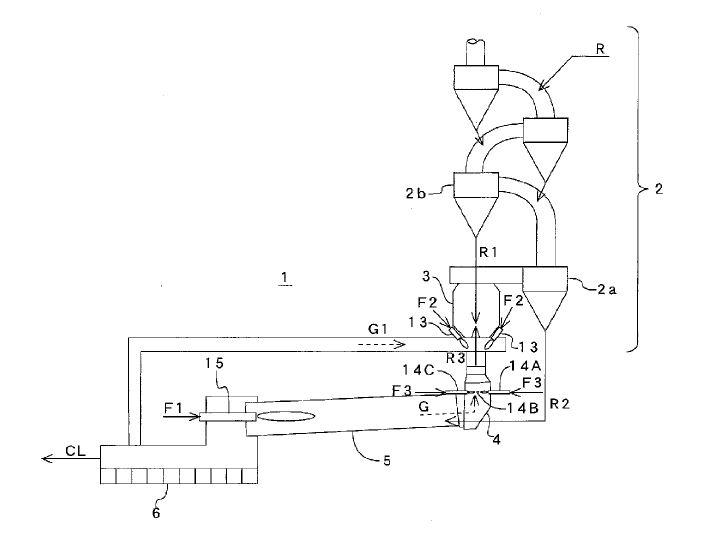

SPZ commissioned the new plant to meet their environmental responsibility, comply with current emission regulations and ensure that they will be able to meet future extensions of regulations. These aims are definitely achieved by the new plant and, using a new waste heat recovery system, power consumption and operational costs are minimized throughout the process. In spring 2010 GEA Bischoff was approached to design a SCR system that would enable the plant to run with a minimum NOx concentration in its flue gas. The company has over 10 years of experience in designing such plants and quickly identified an SCR plant, situated downstream of the kiln bag filter and equipped with a heat recovery system to boost the operating temperature, as the most appropriate solution.

A catalytic reduction of the NOx output requires the operation temperature to be more than 250 °C. To achieve this, the kiln exhaust gas is heated up in a recuperative cross flow heat exchanger supplied by Ecoflex, another member of the GEA Group. In a second heat exchanging step the gas temperature is boosted by a thermal oil loop using back waste heat from the clinker cooler. The NOx content in the exhaust gas can definitely be reduced to below present and even future emission regulation limits.

In a recent interview Dr. Helmut Leibinger, head of plant and process engineering at SPZ, concluded: “GEA Bischoff’s technical experience in planning and construction of process plants together with Rohrdorf’s pioneering spirit were the basis for the successful introduction of the SCR technology in the cement industry”.