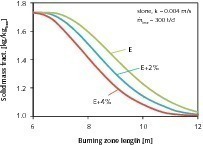

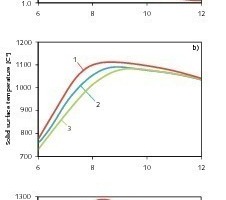

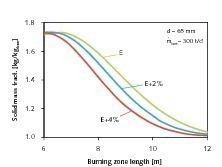

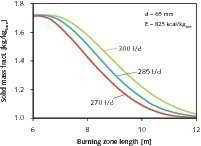

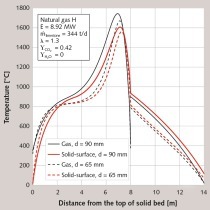

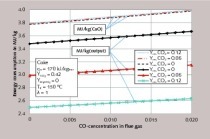

The previous article presented a one-dimensional mathematical model to describe and simulate the lime calcination process in a PFR lime shaft kiln [1]. The model was used to calculate the core/surface temperatures of the solid (limestone lime) particles, the gas temperature, the residual CO2, the pressure drop along the bed height and the local wall heat loss. The effects of two operating parameters, the energy input and the kiln throughput, were investigated.

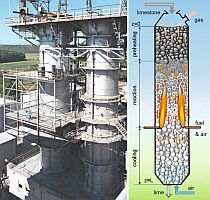

1 Introduction

Lime burning is a complex process due to the variety of parameters which exert influences on the process. In principle,...