Over 900 participants attended the IEEE-IAS/PCA conference 2012 in San Antonio, Texas/USA. The 4-day conference with one day excursion to the TXI Hunter plant and the Cemex Balcones plant offered a full information package on various topics important for the American cement industry.

During the day, a number of different formats were waiting for the participants. Peer-reviewed technical articles, an environmental workshop, keynote lectures and tutorials provided a broad basis for the transfer of knowledge and exchange of information. Almost all topics relevant to the cement industry were covered. A strong focus was placed on emission reduction. NESHAP/NSPS rules were carefully discussed. Technological developments, supplementary cementitious materials, alternative fuels and many other topics were also on the agenda. In the evening, hospitality suites invited participants to intensify discussions about the topics accumulated during the day.

Tutorials

The first conference day was dedicated to tutorials. In a workshop-like atmosphere participants could inform themselves about the following topics:

Automation: Wireless technology for cement plant applications

Drives: Variable types of speed drives, sizing, selection, how to implement into a project.

General practices: Grinding technology: Technical assessment and advances in vertical roller mill projects

Power generation: Analysis for the design of electrical power systems

MSHA Part 46 Annual Refresher Training

Conference

The first conference day started after the welcome address by Corinne Fields (Fig. 1), Chair of the San Antonio Organisation Committee, with an industry outlook by Ed Sullivan, Chief Economist at the PCA. Stronger than expected job creation and the beginning of a construction industry recovery means gains in real construction spending will materialize this year — after seven years of consecutive declines. According to the new forecast from the Portland Cement Association (PCA), increases in cement consumption will follow. PCA revised its fall forecast upward, anticipating a modest 3.7 % increase in 2012, followed by a 7.6 % jump in 2013 and a 14.1 % increase in 2014. The forecast includes marginal improvements in non-residential construction, an upward revision regarding housing starts and an aggressive cement intensity gain, which is the amount of cement used per real dollar of construction activity. “Cement usage is greatest at the early stages of construction with foundation work. The decrease in building starts during the recession had a huge impact on consumption and intensity,” said Ed Sullivan, PCA Chief Economist. “A construction start rebound in 2012 coupled with the competitive price of concrete compared to other building materials translates into increases.” With successive years of economic and employment growth, the structural issues facing the construction industry will diminish”, stated Sullivan. For example, the adverse impact of foreclosures will fade, and return on investment for non-residential investments will improve. Partly because of these improvements, state deficits will eventually be replaced by surpluses. PCA forecasts that all sectors of construction will be positive during 2014-2015, which typically results in large gains in cement consumption.

To follow, a series of articles addressed many important topics, such as mercury emissions, energy efficiency, drives and motors.

Panel discussion

During a panel discussion five different suppliers of vertical roller mills (FLSmidth, BHS, Loesche, Gebr. Pfeiffer, Polysius) presented their solutions for a given task. The target was to set up a cost efficient grinding system with good performance for a vertical roller mill grinding 95 % clinker and 5 % gypsum to 3800 cm2/g Blaine. The equivalent ball mill energy consumption was 36 kWh/t at 200 t/h.

PCA-Environmental Workshop

The workshop featured an update on the National Emissions Standards for Hazardous Air Pollutants (NESHAP) and on Non-Hazardous Secondary Materials (NHSM) and on Commercial/Industrial Solid Waste Incinerators (CISWI) regulations as well as a survey on Continuous Emission Monitoring Systems (CEMs).

Plant tours

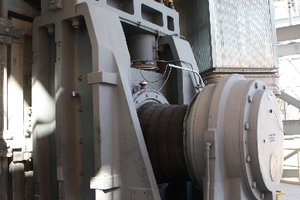

During the plant tour the TXI Hunter plant was visited (Fig. 2). The decision was already made for the expansion project in 2007. Due to the crisis, construction started in 2009. Commissioning is planned for October 2012. The line will be installed by Polysius. A new 5-stage single-string preheater tower, a Quadropol 45/23-440 raw mill with a Sepol 41-QMR separator will be installed. The kiln is a two-pier POLRO kiln fired with a Polflame VN burner (Fig. 3). A 1-string calciner from Polysius and a Polytrack clinker cooler (Fig. 4) will also be installed. A deep pan conveyer is used for clinker transport. The cement is to be produced with a Polysius two-compartment ball mill with a SEPOL NSV 330/0 separator. The homogenising silo and the preheater feeding silos are Polysius Multi-Pack silos.

The second plant visited on the tour was the Cemex Balcones plant. At the beginning of the visit, participants were able to see blasting in the quarry. Balcones has been with Cemex since 1984, the expansion project began in 2006. After the modernization, the plant has a capacity of 2.3 million t/a clinker and 2.6 million t/a cement. The Balcones plant has been the winner of the Cemex Global Safety Award three times. In 2011 the Energy Star from the EPA was awarded for superior energy performance. The plant runs a Hazemag crusher 2500 for primary and secondary crushing and a raw mill LM 46.4 from Loesche. The preheater tower is a 1-string 5-stage preheater with a calciner. The kiln is a two-station KHD Pryorapid kiln with a capacity of 3600 st/d. A KHD PyroJet burner is fed with coke and natural gas, the calciner has a KHD PyroBox burner operated with coke. The cooler is an IKN cooler for 3500 t/d. Tires are fired in the riser duct by a special tire injection mechanism (Fig. 5). The plant runs a KHD coke mill in Line 2. Finish grinding is performed with a Loesche mill LM 56.3+3 (Fig. 6). The kiln and mill baghouse is a TGT Filter from Fives-Solios with pulse-jet cleaning and 7 m bags.