Europe’s largest cement mill goes to Turkey

Within Loesche’s scope of supply are one Loesche Mill Type LM 46.4 to grind cement raw material at a rate of 330 t/h at a fineness of 12 % R 90 µ and a Mill Type LM 28.2 D to grind coal. The design capacity of the coal mill is 30 t/h at a fineness of 3 % R 90 µ. For cement grinding, Nuryol Cimento are convinced of the advanced and innovative Loesche cement grinding technology, including the patented roller pair design, and have therefore purchased a Loesche Mill Type LM 63.3+3, including process filter and fan.

The mill is designed to grind OPC cement with a capacity of 240 tph at a fineness of 3800 cm2/g according to Blaine. This Loesche mill represents the largest vertical roller mill for cement grinding in Turkey as well as in the whole of Europe. It will have a table diameter of 6.3 m and will be driven by a motor with a rated capacity of 7200 kW.

The advanced Loesche technology, ensuring the production of excellent product qualities with a high availability and very low energy consumption of the milling systems, were major decisive factors for Nuryol Cimento to trust Loesche for all three mills.

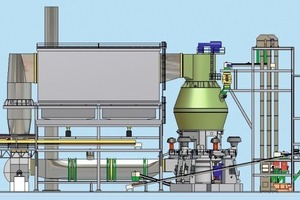

Loesche’s innovative compact plant design for cement grinding plants was another important reason for NuryolCimento to choose a Loesche vertical roller mill for cement grinding. The new plant design from Düsseldorf eliminates the necessity for a large and expensive mill building, leading to massive savings in required plant plot, in cost for structural steelworks and civil works as well as in erection time.

This is, amongst other innovations in this direction, possible due to Loesche’s newly developed LDC classifier. This classifier is equipped with a patented gas flow straightener called “VORTEX Rectifier” which ensures an already homogeneous airstream at the classifier exit. Due to this a horizontal mill exit directly into the mill filter is possible. This leads for example to a reduced pressure drop of the mill system hence to savings in the specific power consumption of the complete grinding system.

www.loesche.com