Modern and economic quarry and resources management

Economic quarrying

I-Site technology is used for surveying, mapping and volume calculations in the cement industry around the world. The ruggedised I-Site 8000 series laser scanners operate in all environments with high quality data recorded in a short amount of time. With an IP65 rating protection against dust ingress, I-Site laser scanners can be safely used in clinker sheds and industrial environments (Fig. 2). The operating temperature is also critical, with a constant operating range from 0 degrees to +50 degrees Celsius being extended on short exposure from -40 ° to +50 °C.

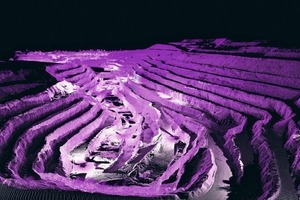

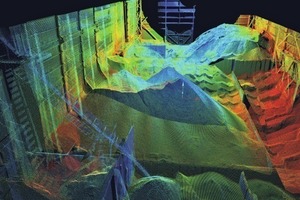

I-Site laser scanners are workhorses when it comes to topographic survey in an open cut quarry. For example, in just four hours a surface area measuring 1500 x 500 m can be scanned from 25 setups. Raw data is loaded into I-Site Studio software to produce a comprehensive 3D model of the active working area. The challenges of scanning stockpiles of clinker, slag, gypsum and limestone are easily met using the I-Site laser scanners. The restricted access of indoor stockpiles is handled by mounting the scanner on a gantry and scanning from above. Volume calculations take just minutes.

Material density can also be determined using the I-Site laser scanners. The scanner is mounted above the truck loading area and the load is scanned as it is being weighed. A model is developed of each material and is then compared to a model of an empty truck, along with the weight of the truck. This then provides the density of the material in the truck.

Improvements in efficiency

Time spent in the field is drastically reduced using the I-Site laser scanners. Using the I-Site Vehicle Mount to allow stop-go scanning means surveying does not interrupt equipment activity in the quarry. The volume of stockpiles is calculated easily by importing data from the I-Site laser scanner into I-Site Studio software. The flexibility to mount the scanner inside sheds or near conveyors means that hard to reach areas can be surveyed effectively.

The long range of I-Site laser scanners (from 1000-2000 m) allows scanning to be conducted remotely, removing the need for site personnel to access unsafe areas or unstable ground. Stockpiles do not need to be climbed on, or unsafe edges approached. Continuous feed mechanisms can continue operating while surveying takes place.

Each year, Maptek invests more than 20 % of its profits back into research and development. New product development and improving existing products are important facets of the business strategy. Maptek products are developed in conjunction with customers and work will continue to provide the solutions which improve the productivity and safety outcomes required by industry.

Case studies

Time to capture data has been reduced by 50 %. Volumes are now calculated with confidence that the data is correct and is an accurate reflection of reality. At another cement facility, an I-Site laser scanner profiled cement inside a silo to better understand how the silo was emptying. The silo was 30 m in diameter and 20 m high, with access from two 0.75 m square roof hatches. The scanner was mounted horizontally and lowered 0.8 m below the roof to achieve 100 % coverage of the cement surface. Over three scans, 1.2 million data points were collected. The data was merged, and unwanted wall and roof data was filtered to create a surface model and contours. The cement surface could then be shown inside the silo.

Within two hours, management had a detailed model of how their silo was emptying, highlighting a significant amount of material remaining on the silo walls and chute. Accurate volumes were easily calculated from the modelled surface which was useful for stocktaking.