ABB expands Dodge Passport selection tool with belt conveyor design program

Passport, an online product selection program, now offers users an application-based approach to quickly and easily design and order mechanical products used in belt conveying applications

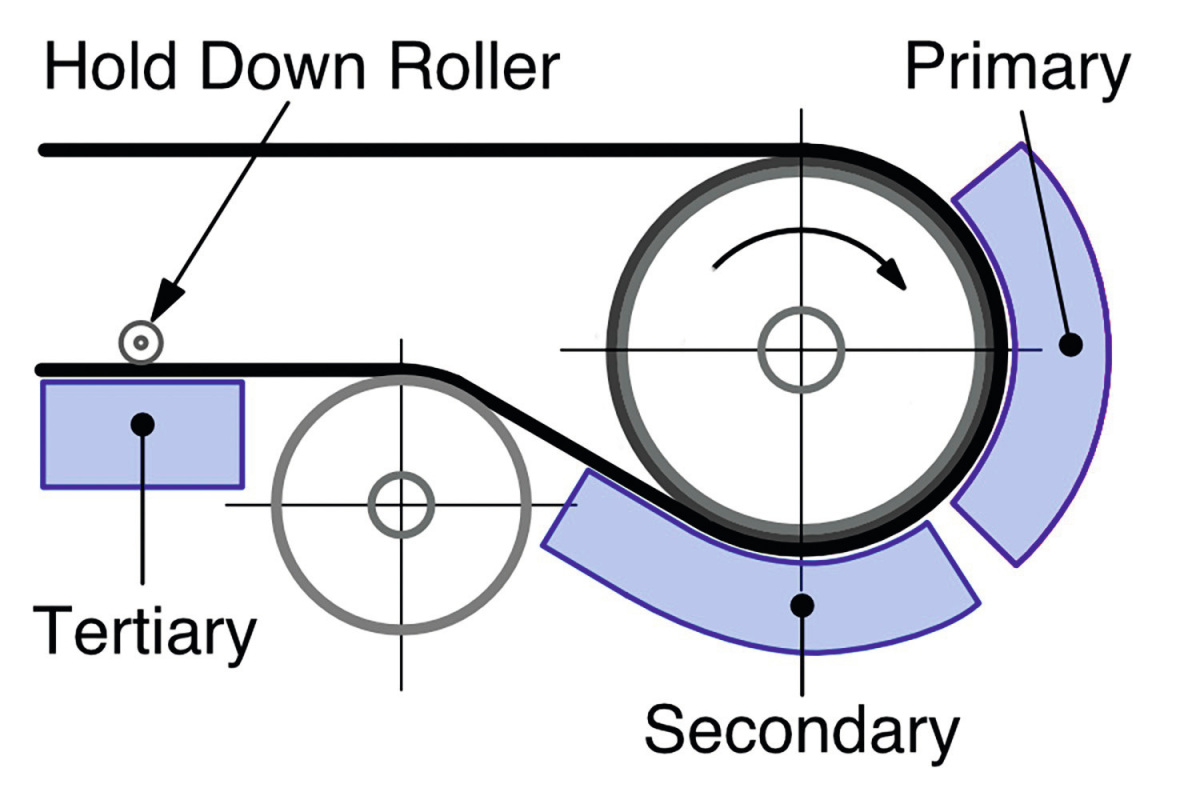

ABB enables customers to design conveyor pulley assemblies and belt conveyors for the first time with its web-based Dodge Passport design tool. These user-friendly programs allow customers to create and order complete application-based solutions for bulk material handling applications typically found in mining, cement, aggregate and grain industries.

Passport’s new conveyor pulley assembly designer allows users to select, quote and order conveyor pulley assemblies complete with shafting and mounted bearings. Real-time pricing and availability enables customers to make cost-effective selections of readily available components. After selections are complete, Passport offers add-to-order capability, allowing customers to seamlessly convert selections into orders via the PT Place e-commerce platform.

For the new belt conveyor design program, Passport uses application-specific design parameters such as capacity, material characteristics, and conveyor geometry to accurately size gear reducers, motors, conveyor pulleys, shafting, and mounted bearings. Passport also delivers a comprehensive summary that includes component details, supporting technical performance data and indexes selections for future reference.

Future Passport capabilities will incorporate additional Dodge mechanical power transmission products, as well as expanding the application-based approach for packaged product solutions to a wider range of common industrial applications.