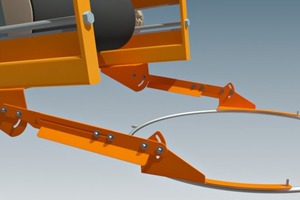

Adjustable bracket for dust suppression ring

Dustboss from PeoriaI, IL/USA has introduced a family of adjustable mounting brackets for the popular DustBoss® DB-RTM series of dust suppressors. Developed in direct response to customer feedback, the new bracket design is available to suit the entire range of ring sizes from 43 to 254 cm, and can be installed in about an hour. The DB-R is engineered specifically for use at conveyor discharge points, designed to create a virtual “curtain” of mist around the material flow for outstanding particle containment.

“Because of the wide variation in conveyor designs, in the past we’ve left the mounting of the rings to the individual customer,” explained Dust Control Technology CEO Edwin Peterson. “But it was clear that customers looked to us for guidance. So now we’ve designed an adjustable bracket that can fit virtually any conveyor design, with movable arms to allow precise location of the atomized mist circle to match the specific conveyor, material and outflow.”

First developed for a coal application, the DB-R fully encircles the discharging material to apply suppression directly as the flow exits the conveyor. With no moving parts, the simple yet effective engineering delivers focused dust suppression on a continuous-duty basis, able to capture fugitive particles on radial stackers and other offloading points with a durable, intrinsically safe design. The solution is straightforward but effective, and customers are finding that it’s well suited to conveyor discharge of sand, aggregates, biomass and other traditionally dusty materials.

“For some bulk material handlers, it can be a very affordable alternative to more extensive dust management tactics,” Peterson said. “Larger operations are finding that the source-point suppression of the DB-R is the perfect complement to their open-area dust control measures.”

The DB-R is currently available in nine standard sizes (43-254 cm) in diameter. Available options for the DB-R include a booster pump to elevate low water pressures, a variety of nozzle sizes/configurations and water filtration. Customers can also order the units with a 2-way valve and/or hose included.

//www.dustboss.com" target="_blank" >www.dustboss.com:www.dustboss.com