Automatic loading and palletising with the Beumer autopac

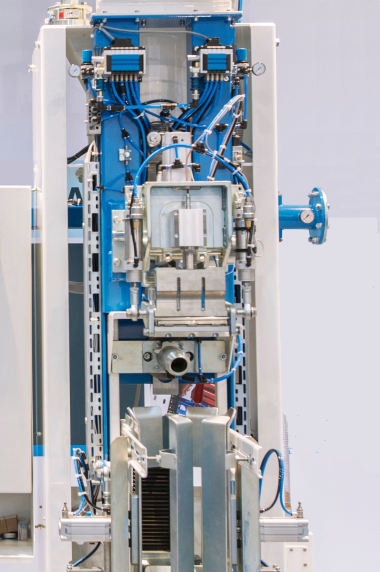

The Beumer autopac of the 2400 and 3000 construction series is a system which enables users to automatically load bagged bulk materials like cement on trucks and simultaneously palletise them – quickly and with the desired packing pattern. The Beumer autopac consumes very little energy, is reliable even in dusty environments and can be easily operated and maintained. The machine is also suitable for paper, HDPE and PP valve bags.

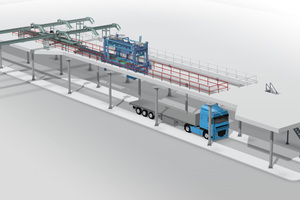

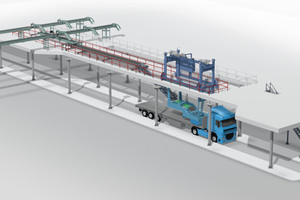

The truck with the empty loading space slowly stops under the Beumer autopac. To load and palletise the cement bags, the employee enters the number of bags, the packing pattern and the desired number of rows and layers in the Beumer Group Human Machine Interface (HMI). Laser positioning aids have been mounted to the left and right of the Beumer autopac. They project the outer contours of the machine with a clearly visible red beam on the loading space, helping the operator to position the loading head on the truck.

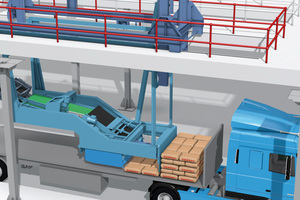

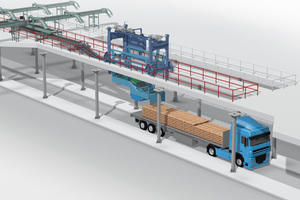

From its starting position, the Beumer autopac now starts the automatic loading process, bag by bag, directly from the filling machine via belt conveyors onto the truck. “With our Beumer autopac, we have a system in our product range that can load trucks automatically,” explains Markus Peitzmeier, Senior Sales Manager at Beumer Group. “And it does so extremely reliably.” The use of an electronic bag counting system makes sure that the truck is neither underloaded nor overloaded. Manual corrections are completely omitted. “The program control recalculates the height setting for each layer,” Peitzmeier describes. In order to attain the highest possible degree of stability for the whole load on the truck, and in order to optimally utilise the loading space, two mirror-inverted layers are palletised next to one another. Two belt conveyors positioned one above the other flatten the bags before the loading process and thus remove the air from them. After being positioned, the bags are also pressed by the loading head, which makes the stack more compact and more stable. Meanwhile, the next layer is already being prepared. The bag feeding lines can be adapted to the customer‘s installation conditions. Corresponding technical solutions are available for variable conveyor lines.

“The Beumer autopac is ideally suited for use in emerging countries, where the transhipment of bagged bulk goods is increasing. In these countries, labour costs are rising, and it is becoming more and more difficult to find appropriate personnel for this kind of work,” says Peitzmeier. Manual truck loading is exhausting and usually requires two people who alternate with their colleagues for each loading process due to the heavy physical work involved. Furthermore, there is the high level of dust formation, which negatively affects the employees’ health. During the manual loading process, the loading performance as well as the quality of the bag stacks often fluctuates. “These problems are eliminated with our Beumer autopac,” says Peitzmeier. One employee is able to operate more than one machine.” This enables owners to optimise processes, achieve high loading capacities and work very efficiently from bagging up to loading.

Depending on the bag dimensions and their length and width ratio, the user has flexibility in layer formation. Patterns of ten, twelve and twenty bags per layer are possible. The very low positioning height of the loading head contributes to the gentle handling of the bags, as they are supported during the loading process and not lifted or possibly deformed, as is the case with vacuum suction modules.

The system provider uses the specially developed Beumer Group HMI for operating the Beumer autopac. This is a touch panel with optimised user interface and graphic navigation. This operator panel provides users with an easily understandable and intuitive interaction concept, enabling them to define efficient working sequences.

Sustainable all along the line

Beumer Group is committed to evaluating its products comprehensively on the levels of economy, ecology and social responsibility. “We follow a total value of ownership (TVO) approach. This means, we consider the system in its entirety, not only from its cost side,” says Peitzmeier. For example, we continuously look to reduce energy and resource consumption in the production cycle and during operation of the systems, all the while keeping emissions to a minimum. When loading 3000 bags per hour, each weighing 50 kg, power consumption is held below 0.1 kWh per ton.

The Beumer autopac is both energy-efficient and extremely robust, as demonstrated by the many systems that have been in daily use for decades. “The machine has been designed for heavy-duty operation to resist extreme ambient conditions like heat, high air humidity, dust formation and the three-shift operation in packing plants”, says Peitzmeier. In addition, the owner profits from the smaller footprint compared to other loading systems. With its compact design, the Beumer system can be quickly and easily maintained, is reliable and safe to operate. “This is supported by the fact that we have only integrated electromechanical components,” describes Peitzmeier. “This eliminates the need for hydraulic or pneumatic components, which wear out fast or require expensive compressed air.” As for the sensors, the system provider installs contactless proximity switches that reliably transmit signals without mechanical contacts. The use of high-quality photocells ensures signal transmission even under difficult environmental conditions. In addition, the sensors used increase both machine capacity and product quality and make sure that a wide variety of materials and bags is safely handled with the Beumer autopac. “Remote maintenance is also possible, around the clock, every day of the week, during which we can connect to the system from the Beumer site,” says Peitzmeier. “This increases system availability, because we can react faster without having to travel long distances.” The pre-assembled modules allow the Beumer autopac to be quickly installed and commissioned at the customer’s site.

“The fully automatic loading process enables users to achieve a constantly high loading performance and stack quality,” promises Peitzmeier. “Our Beumer autopac has proven itself in the cement industry world-wide for decades.”