Contributing to community sustainability: The role of co-processing municipal waste in China

The CSI “Technology Roadmap: Low-Carbon Transition in the Cement Industry” primarily considers the use of alternative fuels to reduce fuel cost at the same time as reducing CO2 emissions. However, there are other reasons to co-process waste in cement kilns, namely the disposal of municipal and industrial wastes that would otherwise be difficult, more expensive or more hazardous to treat. Disposal of municipal solid waste (MSW) and sewage sludge in China provides a good case study for this: three projects on disposal of MSW in cement kilns come from some of the leaders in the field, Huaxin Cement, Sinoma International and Sinoma Cement.

Introduction

Coal is currently the fuel that is most widely used in cement production, representing 70 % of global thermal energy consumption. Other fossil fuels, including petcoke, contribute 24 % and alternative fuels just over 5 % of the global thermal energy use in the sector. Switching to fuels that are less carbon intensive is forecast by CSI to enable a reduction from 88 kgCO2/GJ to 58 kgCO2/GJ by 2050 – a reduction of 34%.

Many readers will be familiar with the CSI “Technology Roadmap: Low-Carbon Transition in the Cement Industry” published by the International Energy Agency (IEA) and the World Business Council for Sustainable Development (WBCSD). It is worth recalling that according to this roadmap, “switching to alternative fuels that are less carbon intensive than conventional fuels delivers 0.9 Gt CO2 or 12 % of the cumulative CO2 emissions savings by 2050 globally in the 2DS (2 °C scenario) compared to the RTS (reference scenario). This is equivalent to 42 % of current direct CO2 emissions of global cement production.”

The CSI roadmap primarily considers the use of AF to reduce fuel cost at the same time as reducing CO2 emissions. However, there are other reasons to co-process waste in cement kilns, namely the disposal of municipal and industrial wastes that would otherwise be difficult, more expensive or more hazardous to treat. Disposal of municipal solid waste (MSW) and sewage sludge in China, which we explore in more depth later, provides a good case study for this.

Municipal waste situation in China

The production of MSW has been increasing rapidly in China - according to the World Bank, China surpassed the United States as the world’s largest waste producer in 2004. The increasing volumes and diminishing remaining landfill space have led to a serious crisis which has been described as a “garbage siege” in some Chinese cities.

In 2019, 228 million t of MSW were collected, of which 51 % was landfilled, 45 % incinerated with just 3 % disposed of by other methods, mainly by co-processing in cement kilns.

Though landfill is the primary means of waste disposal, the remaining capacity is limited. In addition, due to toxic emissions, waste incinerators have aroused a great deal of public opposition. Air pollutants, especially dioxins and furans, are emitted from incinerators and long-term exposure can cause severe harm to human and environmental health. Although efforts have been made to clean up emissions from incinerators, the Chinese public still doubts its safety and has noisily opposed the construction of incinerators in many cities.

Co-processing of waste in cement kilns has many advantages over incineration, most important of which are environmental: there are no dioxins emitted nor any bottom ash in which heavy metals are concentrated. In addition, it is less expensive to operate than traditional incinerators, and does not require high levels of investment since it utilises existing cement kilns to dispose of the waste.

The following case studies on disposal of MSW in cement kilns come from some of the leaders in the field, Huaxin Cement, Sinoma International and Sinoma Cement.

MSW – Huaxin Changshankou project

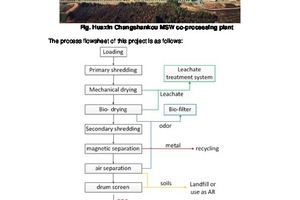

The Huaxin Changshankou MSW pre-processing project, located in Wuhan, began operation in 2018 with a design capacity of 2000 t MSW per day (t/d). In 2019 the actual amount of MSW processed was 358 000 t (Figure 1).

Before this, there was only a 5 MSW incinerator and a 1 MSW pre-processing plant for cement co-processing (Huaxin Chenjiachong) in Wuhan, with a total disposal capacity of 7000 t/d, which was unable to safely dispose of the 10000 t/d generated in 2018 (Figure 2).

At Changshankou, the MSW is received at 55 % moisture and is sorted into various output streams by a series of processes including shredding, mechanical drying, bio-drying and air separation (Figure 3). The output streams are RDF which is co-processed at Huaxin cement plants as AF; metal which is reclaimed and sold to recyclers; inorganic soils which are co-processed at Huaxin cement plants as alternative raw material (AR); leachate which is discharged after treatment at a sewage treatment system; and odour which is collected and treated by a bio-filter system (Figure 4).

The RDF output stream is transported to the Huaxin Yangxin cement plant for co-processing as AF. This cement plant has two kilns with pre-calciners and a clinker production capacity of 5000 t/d and 4800 t/d. The feed point for RDF is at the bottom of the pre-calciner to use the high temperature there and minimise the influence on kiln conditions. The RDF disposal capacity of each kiln can reach 700 t/d (Figures 5 and 6).

Before feeding, every batch of RDF is tested to monitor chlorine (Cl), sulphur (S) and heavy metal content, which can have harmful effects on cement quality. A by-pass system is used to control Cl levels circulating in the kiln.

As for the issue of dioxin emissions concerning the general public, according to long-term test data of the co-processing plants in Huaxin, the emission value of PCDD/Fs in the flue gas is well below the national emission standard (0.1ng TEQ/Nm3). Sufficient burning at high temperatures, the alkaline atmosphere in the kiln, adsorption of PCDD/Fs on raw meal, and the efficient capturing of dioxin particles in the dust collector bag filter may all contribute to the low levels of PCDD/Fs.

The total construction investment of this project was US$ 60 million. Revenue is generated by the tipping fees, and costs savings come from replacement of coal by RDF, which has a heat value of 2500 kcal per kg (about half of coal). In addition, CO2 and NOx emissions from the kiln are reduced when burning RDF.

MSW – Sinoma-Envir at Lishui Tianshan Cement

Sinoma International Environmental Engineering (Sinoma-Envir) is part of Sinoma International and a leading supplier of environmental technology and services. It also operates recycling facilities on government concession. The latest co-processing technology for MSW features a hydraulic sorting system for inorganic matter and a pulping system for kitchen waste. This system is designed to have a higher recycling rate and can be used to recycle wet biodegradable waste that many Chinese cities have started pre-sorting at households. The technology has been applied in the Lishui Tianshan cement plant (located in Nanjing, Jiangsu) in 2019 at 500 t/d capacity, and has already demonstrated the potential of higher MSW recycling rates.

The process starts with separating MSW (without pre-sorting) into RDF, ferrous metals and kitchen waste using Sinoma-Envir’s high accuracy sorting technology. Ferrous metals are sent to recycling companies; kitchen waste is fed to the hydraulic sorter, and inorganic matter is separated and fed into the cement raw mill as alternative raw material (AR). The residue from hydraulic sorting is blended with waste leachate and fed into a pulping system to be further separated into organic liquid and light RDF. After sorting, the organic liquid is delivered to a CSTR to produce biogas which is used to generate electricity. The light RDF will be mixed with the RDF from the initial sorting process and pushed through a dewatering screw press to reduce the moisture to < 35 %, becoming alternative fuel for the cement kiln (Figure 7). The power consumption of the dewatering screw press system is lower than that of most alternative RDF dewatering technologies. The entire workshop is kept at slight negative pressure, and equipment in the workshop is properly sealed, reducing dust emissions and ensuring good air quality inside and around the workshop. The hydraulic sorting and pulping system can also be used to process and recycle wet waste (Figures 8 and 9).

In order to reduce RDF’s impact on clinker production, a pre-combustor is added to the calciner system. RDF is fed into the combustor to improve stability of calciner system operation. In addition, an Expert Process Control system is integrated into the operating system for automatic temperature control and to lower impact on the calciner due to fluctuations in RDF calorific value, thus ensuring quality and the clinker production rate.

By using RDF in the fuel mix, the NOx emission of the cement kiln is reduced. Dioxin emission of the system is also below the national standard of 0.1ng TEQ/m3. Emissions of other pollutants, including SOx, heavy metals, chloride, fluoride, radio-active substances and VOCs, are all controlled within national emission limits. The technology also demonstrates good economic returns. A cement kiln co-processing facility at 500 t/d capacity can, on an annual basis, save 30000 t of coal, substitute 3000 t of clay as alternative raw material and generate 10 GWh of electricity.

MSW – Chaohu Sinoma Cement

The project is located in Chaohu, Hefei city, Anhui Province, and processes about 500 t/d of urban and rural household waste. Before co-processing, the waste was landfilled. The project uses the third-generation technology of Sinoma-Envir. The project started operation on May 15, 2017. The total investment of the project covering an area of 20000 m2 was about RMB 120 million (€ 14.95 million). By May 2020, 520 000 t of household waste had been disposed of at this facility (Figure 10).

The project pre-treats MSW to separate into combustible, non-combustible and leachate through crushing, screening and air separation. The combustibles are fed into the preheater calciner, the non-combustibles into the raw meal mill, respectively serving as an alternative fuel and the alternative raw materials.

Measures taken to maintain the quality of cement includes a chlorine bypass system to solve the influence harmful elements of hot raw materials (potassium, sodium, SO3, chloride ions): kiln ash is transported to the outlet of the grate cooler and evenly mixed with clinker. This avoids the build-up of harmful elements and its effect on cement quality.

The project is characterised by no external waste or secondary pollution. It has very low dioxin emissions (average 0.045ng TEQ/Nm, compared to the national standard of 1.0ng TEQ/Nm and EU standard of 0.1ng TEQ/Nm). Leachate is treated in an up-flow anaerobic sludge bed reactor and membrane bioreactor and uses dish-tube reverse osmosis. After treatment, water enters the circulating cooling water system for reuse, which achieves liquid discharge.

Deodorisation control is achieved through negative pressure ventilation, biological purification and high temperature incineration system.

Key process challenges include grinding fibres and plastics in the roller press; increase in chlorides; calciner temperature fluctuation caused by inconsistent feed; and skin formation in the preheater and kiln. The overall impact on clinker quality can be a reduction in 3-day strength by 1-2 MPa.

Operating costs (excluding construction investment): operation cost includes labour, electricity fee, equipment operation and maintenance, equipment depreciation, disposal of leachate, chemical and biological agents of deodorisation control, etc. Total operating cost is about 120-150 RMB/t (approx. € 14.95).

At present, the project generates income by subsidies from government, and the subsidies are calculated by the government on the basis of actual processing capacity.

Sewage sludge project – Longwangzui project

The Longwangzui sewage sludge disposal plant went into operation in 2012 with a capacity of 400t/d. In the past, sewage sludge was mostly treated by landfill in Wuhan, and the Longwangzui plant is the first sewage sludge co-processing project which can completely realise safe processing and use of sewage sludge. The plant now serves 10 domestic sewage treatment plants in Wuhan. In 2019, it processed 120 000 t of sewage sludge. At the Longwangzui and Nantaizihu sewage sludge disposal plants, Huaxin treated 80% of the sewage sludge generated in Wuhan (Figure 11).

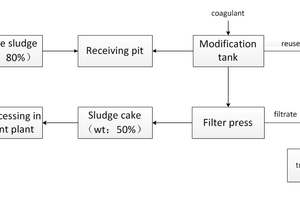

Sewage slurry is transported by pipeline or tanker trucks to the receiving pit and then transferred into tanks for pre-process conditioning. In this step, the sludge is prepared to the appropriate moisture content for filter pressing, and FeCl3, CaO or other kinds of coagulant are added and mixed well. Modified slurry is delivered into a frame filter press. The moisture content is reduced to 50 % after filter-pressing and the sludge cake has a dry appearance and is easy to transport (Figure 12).

The press filtrate is returned to the sewage treatment plant. The plant ventilation system is under negative pressure and prevents odour escaping. A chemical scrubber is used for odour treatment. Filter cake sludge is transported to the Huaxin Daye cement plant for co-processing. The kiln used for co-processing has a pre-calciner kiln and the clinker capacity is 4500 t/d. In 2019, 165 000 t sewage sludge was co-processed in this kiln. The feed point is in the lower pre-calciner, for the high temperature there and less influence on kiln conditions (Figures 13 and 14).

Most of the Cl- in the flocculant is taken away in the filtrate, so there are few harmful effects on clinker and kiln operation when co-processing sewage sludge. The content of Cl-, S and heavy metals which have harmful effects on cement quality are monitored. The heavy mental content of clinker is also tested (Figure 15).

Experience has shown that co-processing sewage sludge has a significant impact on reducing NOx emissions from the cement kiln. Sewage sludge disposal is safer and cleaner than MSW, it is less likely to catch fire and there is no leachate problem. Nevertheless, the sewage sludge pre-processing plant is usually built in urban districts (near to the sewage plant for convenient transport), and therefore it is crucial to control the odour effectively (Figure 16).

The direct revenue for this project comes from tipping fees and there are significant cost savings from reduced NOx SNCR reagent (ammonia).

Conclusion

Although the portion of municipal waste being co-processed in cement kilns in China is still only 3 % of the total waste generated, the technologies used have been proven over several years to be both safe and economical. Tipping fees are typically around half of the fees and subsidies required by incinerators. Even more importantly, the key environmental problems of incinerators, namely dioxin emissions and safe disposal of ash, are not encountered when co-processing MSW in cement kilns.