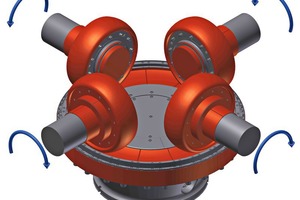

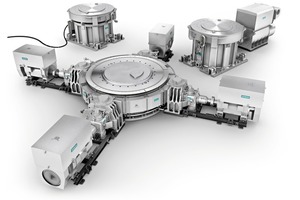

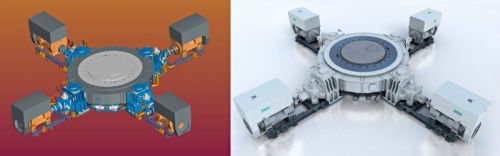

Drives for large vertical roller mills

The continuing development in the size of vertical roller mills and their corresponding increase in market share when compared to other mill types in the cement industry is only feasible with adequate drive solutions. In this article we profile the different solutions and review projects where these new drive solutions are already integrated.

1 Introduction

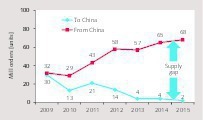

Vertical roller mills (VRM) have dominated raw materials and coal grinding for many years, and in cement and slag grinding the market share of VRM is constantly growing with larger mill sizes. In the period 2009 to 2015, of the 1209 new mills that were ordered by the cement industry outside China, 661 units or 55 % were VRM, the remaining 45 % were other types such as ball mills, high-pressure grinding rollers (HPGR) and horizontal mills. Figure 1 shows how the mill market potential developed and how the market share of VRM changed. A large quantity of mills outside China has...