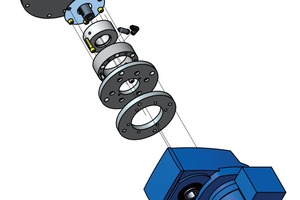

Easy Gasket – innovative sealing system for screw conveyors

The gaskets used to protect the drive and bearing systems of screw conveyors while preventing the escape of bulk material are subject to lots of wear and tear. The new Easy Gasket system by SHA GmbH provides a revolutionary, reliable solution to that problem and even keeps the shaft journal from wearing down at the same time.

In the Easy Gasket system engineered by SHA in cooperation with producer Cinch Seal, the seal face, as the major sealing surface, is not situated between the shaft journal and the gasket, but between a pair of rotor cups comprising chemically linked PTFE rings and a hardened aluminium housing. Within the housing, the seal elements are subject to compression generated by an elastomer rubber boot mounted firmly on the shaft journal. Force of compression ensures that the rubber boot riding the shaft applies sufficient surface pressure to the rotor cups in the aluminium housing to keep them in a state of floating rotation. By means of air compression, a defined pressure pushes the rotor cups up against the housing to yield a liquid-tight zero gap. Following an initial running-in time of 2 or 3 operating hours, no measurable amount of air is consumed.

For nearly two years now, SHA GmbH has been using these gaskets as a standard seal solution with the following main merits: no abrasion of the shaft journal, unimpeded linear expansion of the shaft, no gasket damage due to radial motion (rotating unbalance) of the shaft, no need for gas purging, no lubricants required, no bulk material contamination, longer service life, lower operating and maintenance costs and, of course, higher availability.

//www.sha-germany.de" target="_blank" >www.sha-germany.de:www.sha-germany.de