Exchange of ideas and experiences on gypsum products in Russia

A comprehensive program of lectures also reflected the extraordinarily good response to the conference. The conference volume handed out at the beginning included 38 lectures (all in Russian), most of which were given.

modified gypsum binders and binder systems containing calcium sulphate,

mode of operation of admixtures during the hydration process,

use of residual products during the manufacture of calcium sulphate building materials.

R. Rakhimov investigated the influence of ceramic dust and blastfurnace slag in gypsum composite binders on the strength and moisture resistance. The compressive strength amounted to approx. 25 MPa and the softening coefficient to approx. 0.75. Such binders will be used for plaster, masonry mortar and packing mortar.

The focus of Dr. H.-B. Fischer’s lecture was on the improvement of the fire resistance of gypsum boards. A method was presented to quantify the cracking after a fire test. Furthermore, the effects of various additives were described as regards fire resistance.

The lecture given by A. Pustovgar was the basis for many discussions. With the help of several different examples, he explained the possibilities for the use of non-linear waves in the building industry. It also seems to be possible to use this method in the gypsum industry for example to save admixtures and for low-wear mixing.

Vasily G. Klimenko described theoretical aspects for the stimulation of the solidification process of anhydrite A II. His onclusion was thata mixed stimulation is not very effective.

Skorzov presented the comparison of Russian and European standards for gypsum boards, and A. Bykov talked in his lecture about further training carried out by the Knauf Group.

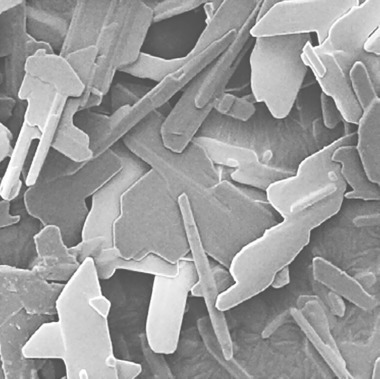

M. Garkavi talked about the structure of calcium sulphate scale. An increase in strength is achieved by the addition of nanotubes and polymer powder. He thinks that the compaction of the structure is due to an increase of the contact points between the gypsum crystals.

Y. G. Meshtsheryakov and others outlined the possibilities of using phosphogysum for the manufacture of building components.

The use of waste for the manufacture of binders and gypsum components containing calcium sulphate played an important role in many of the lectures given, amongst others, by A. A. Ponomarenko et al., S. V. Sytshugov et al., V. B. Petropavloskyaya et al., B. S. Batalin et al.

M. A. Micheyenkov, E. Potapova as well as Khaseyev and others reported on the possibilities to improve the moisture resistance of gypsum components.

Even the organizer did not expect so many requests to give lectures. Therefore, the times for questions had to be extremely restricted. However, this did not affect the exchange of ideas, since there was enough time for discussions during the breaks, the reception and the excursions. The supporting program consisting of a plant tour of the Knauf works at Kungur as well as a visit to the anhydrite ice cave near Kungur was welcomed by the participants at the conference. A boat trip on the river Kama and a visit to the museum during the last day were an opportunity to become more familiarized with the host town of the 6th Gypsum Conference.

The scientific lectures showed the increased commitment in Russia’s universities as regards the building material gypsum. The European plant construction companies and admixture producers were able to present themselves to the Russian market in the desired manner. During special discussions it became clear that the potential of the Russian gypsum industry is far from exhausted. Many thanks to the organizer of this very successful conference and to the participants. Perm was certainly worth a trip in every respect!