Extended Open Time – the need for standardization of an important characteristic of tile adhesives

The EN 12004 defines the characteristics of ceramic tile adhesives. Because these materials are applied as pastes which undergo reactions to be turned into hard bodies the norm defines the characteristics of both, the initial fresh stage and the final hardened stage. A recent reworking of the EN 12004 targets to delete the fresh mortar characteristics and parts of the strength characteristics. Only the classifications of normal cementitious adhesives (C1) and fast-setting adhesives (F) will be kept in the norm. Deleting the classification E for Extended Open Time bears the risk that the number of failures will increase. The reason is that a standard Open Time of 20 min is good enough for normal conditions. But for warm temperatures and/or windy conditions an Extended Open Time of 30 min provides better security for good wetting of the tiles, which is a precondition for a durable adhesion.

1 Background situation

Adhesives for ceramic tiles are standardized by the EN 12004, which is subdivided into two parts. Part 1 contains the requirements, assessment and verification of constancy of performance, classification and marking [1]. Part 2 describes the test methods [2].

The EN 12004 became a global reference (e.g., ISO 13007) for all players in the market such as raw materials suppliers, mortar manufacturers, architects, engineers, contractors and tile layers.

However, recently the EN 12004 was reworked with respect to the cementitious ceramic tile adhesives and the goal to eliminate all installation characteristics from the norm and retain the so-called essential characteristics, only. Thereby, the classification C2 (cementitious adhesive with improved characteristics), E (Extended Open Time), T (slip resistance), S1 and S2 (special deformability) will be deleted from the EN 12004-1. Only the two classes, C1 (normal cementitious adhesive) and F (fast setting) are kept in the norm.

The goal of this paper is to demonstrate that the Extended Open Time is a key characteristic of an adhesive and should therefore not be deleted from the norm.

2 Extended Open Time – an important characteristic

Recently, the author has portrayed the many technical aspects of tiling technology at the heart of which is the EN 12004 (see Image 1 in Zurbriggen et al. 2020 [9]).

Adhesive mortars are reactive materials which are applied in a pasty state and harden to provide adhesion. The quality of adhesion is dependent on the quality of contact between the trowelled mortar layer and the tile. Therefore, (i) fresh mortar properties such as the rheology (e.g., T class, which refers to slip resistance for wall tilings) and the Extended Open Time performance (E class, which describes a prolonged wetting capability of the trowelled mortar layer), (ii) the application procedure defining the maximum embedding times and (iii) the application techniques (floating versus floating-buttering) predict the quality of primary wetting of the mortar-tile interface and the resulting adhesion.

Given by the reactivity of cementitious adhesives and the processes at the mortar interfaces, adhesion must be regarded as the result of a dynamic evolution.

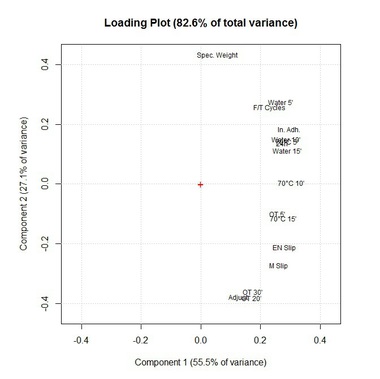

Figure 1 illustrates the Open Time performance of four laboratory cementitious tile adhesives (F1, F2, F3, F4) measured according to EN 12004-2. Thereby the mortar is trowelled under climatic conditions of 23 °C/50 % relative humidity and 5, 10, 20 and 30 min later porous tiles are embedded. If the tiles, embedded 20 min after trowelling provide a 28-day-adhesion strength > 0.5 N/mm2, the Open Time of this particular formulation is 20 min. An Extended Open Time refers to formulations, which provide a 28-day-adhesion strength > 0.5 N/mm2 with an embedding time of 30 min.

Standard or Extended Open Time is a normative value gained under controlled laboratory conditions. It allows to differentiate standard products from special products classified by an E for Extended Open Time.

It must be considered that on construction site two factors are fundamentally different: Firstly, after an area of 1-2 m2 is covered with the adhesive mortar, the tile layer starts embedding tiles in one corner of the trowelled field and continues until all adhesive is covered by tiles. As a result, the individual embedding times of the tiles can range from immediate to about 15 min. Secondly, the climatic conditions on construction site can be much more severe than in the laboratory. Direct exposure to sunlight, dry air or wind can accelerate the skin formation on top of the trowelled mortar layer and the adhesive loses its property to wet the tile. Oberste-Padtberg and Sieksmeier (2007) [5] have demonstrated that an increased airflow can reduce the Open Time performance drastically from 30 min down to 10 min, only.

Keeping in mind that (i) the main property of an adhesive is a durable adhesion, (ii) a durable adhesion is dependent on the primary wetting property of the adhesive and (iii) the primary wetting property is a dynamic process, we have to consider these dynamics when characterizing materials.

Open Time is about these dynamics: It describes the loss of adhesion with increasing embedding time. And a ceramic tile adhesive with an Extended Open Time (E class) such as the formulation F1 in Figure 1 provides premium wetting properties over the first half an hour under laboratory conditions. Formulation F2 still sharply fulfills the criteria for class E, whereas formulation F3 is not achieving the E class. Formulation F4 is not even achieving a Standard Open Time of 20 min.

Based on the data of Figure 1 it is evident that formulation F1 is best suited for a durable tile installation. Formulation F2 shows a similar pattern at lower adhesion strength still fulfilling the requirements for E classification. Formulations F3 and F4 display a steeper loss on adhesion strength with prolonging embedding time. This indicates a faster skin formation as illustrated for formulation F3 by the three insets in Figure 1. As soon as the wetting percentage drops below 50 area%, the resulting adhesion strength falls below 0.5 N/mm2.

3 Information for manufacturers and applicators

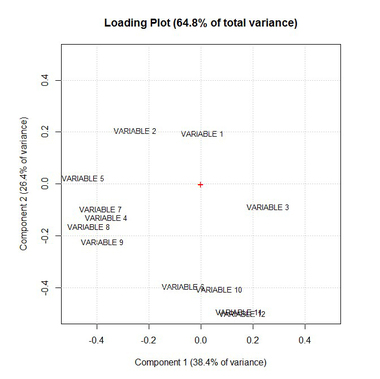

Facing the reality of construction sites where embedding times are ranging from 1 to 15 min or even longer, we need a standard which addresses this reality. Knowing this, manufacturers and raw materials suppliers are developing materials under the aspect of Open Time performance (Figure 2). Figure 2 illustrates that with increasing embedding time (from 10 to 20 and 30 min) both, the wetting area percentage (measured by a procedure similar to the abandoned EN 1347; Zurbriggen et al. 2011) [6] and the resulting 28-day-adhesion strength decrease in general by a similar factor. Therefore, except for the black arrow of formulation F1, the others have an approximate mean slope of -0.1 N/mm2/-15 area%.

The vertical red line marks the 0.5 N/mm2 treshold value. Mortar formulations which understep this treshold after an embedding time of 30 min do not have an Extended Open Time, thus will not be classified by an “E”.

The data displays that formulation F3 does not fulfill the E classification because its adhesion strength drops to 0.42 N/mm2 when embedding time is 30 min. Changing the binder system (F4) makes things worse. This formulation does not fulfill any Open Time standard and is therefore not recommended for tile application. Formulation F2 loses its performance mainly when the embedding time is prolonged from 20 to 30 min but still fulfilling the critical value of 0.5 N/mm2 for the E classification.

Formulation F1 shows a different behavior than F2-F4. Its wetting percentage drops in about the same manner, but the resulting adhesion strength is not affected at all. F1 can retain its adhesion property above 0.8 N/mm2 until an embedding time of 30 min. This indicates that the skin is formed but the growth in thickness of that skin is decelerated, still allowing the fresh mortar underneath the thin skin to break through and wet the tile as it is pushed into the combed mortar bed.

Such a formulation provides security, for challenging conditions on the construction site such as reduced humidity, increased temperatures and airflow.

4 Durable installations

Both, ceramic tiles and tile adhesives are semi-finished products. Thus, the durability is dependent on the quality of the installation work. The experienced tile layer is aware of the dynamic loss of wetting of a trowelled layer of adhesive and is therefore observing the wetting properties on the construction site by the “finger test” and periodic removing of an embedded tile for the inspection for a full wetting of the rear side (Zurbriggen and Pass 2015) [7]. If not fully wetted, the trowelling field should be reduced in size to ensure shorter bedding times for the last tile of a series.

The quality of a durable tile installation starts with purchasing an adhesive with Extended Open Time. The E classification provides security for unforeseen conditions and the situation on the construction site, still allowing the tile layer to ensure a proper wetting of each individual tile.

Not to forget, damage corresponds to the situation when one tile, only, falls off.

Greminger et al. (2010 [4]; see also Table 2 in Zurbriggen et al. 2020 [9]) have conducted an outdoor damage study over three years and investigated the propagation of cracks underneath tiles. They concluded that a primary wetting is a precondition for a durable adhesion under any climatic conditions, whether dry, wet, hot or freeze/thaw. Greminger and co-workers identified a long Open Time as key characteristic of an adhesive able to provide a primary good wetting leading to a durable adhesion.

5 Conclusions

What happens at the mortar surface before tile bedding, predicts the degree of wetting when the tile is laid. Because the mechanisms at the mortar surface, such as skin formation are time dependent, the wetting properties change with time, as well.

Open Time describes exactly these dynamics. It defines the maximum exposure time of the trowelled mortar (before the tile is laid) with a corresponding 28-d-adhesion strength of 0.5 N/mm2.

The Open Time is therefore the essential characteristic of a reactive adhesive. An adhesion of > 0.5 N/mm2 after an embedding time of 20 min is required for the C1 classification. But under severe conditions on construction site a C1 classified adhesive mortar can be challenged to its limit. Therefore, an Extended Open Time with an adhesion of > 0.5 N/mm2 after an embedding time of 30 min provides security for a durable tile installation.

Tile applications under hot and/or windy conditions require great care of the tile layer to keep bedding times accordingly short in order to ensure a proper wetting and resulting durable adhesion. A ceramic tile adhesive with a classified Extended Open Time supports the quality of the tiler’s work and contributes to sustainable construction work.

When the E classification is deleted from the norm, then the market loses a key criteria and the awareness that the essential characteristic of a ceramic tile adhesive is the Open Time.

Deleting the E classifications for Extended Open Time and the others such as C2, T, S1 and S2 will erode references for orientation in the development, selection and application of these materials. This will increase confusion and misconception and the numbers of failures in the future.

![1 Adhesion strength over time. The 5 min value of the C1 formulation (F3) is higher than that of the C1E formulation (F2). The loss in adhesion over time (∆strength/∆time) is less for the C1E formulation than for the C1 formulation. Glass plate images illustrate the decrease in wetting area percentage of the formulation F3 from 80 % to 55 % and 33 % as embedding time is prolonged from 10 to 20 and 30 min, respectively (Data is taken from Zurbriggen et al. 2011 [6] and listed in Table 1; for further explanations see text)](https://www.zkg.de/imgs/1/7/1/1/1/1/3/tok_f9c9084e27e0e80991c65227bb9d8dc8/w300_h200_x600_y516_Application_Zurbriggen_Extended_Open_Time_Figure1-29227ee48e768c52.jpeg)

![2 Wetting area percentages (vertical axis) versus 28-day-adhesion strength (horizontal axis) as a function of embedding time. Green diamonds, blue quadrangles and red triangles refer to embedding times of 10, 20 and 30 min, respectively. The stippled lines mark the areas of all data points with a given embedding time. Black arrows indicate loss of performance of formulations F1-F4 with increasing embedding time with respect to both, wetting area percentage and resulting 28-d-adhesion strength. (Data taken from Zurbriggen et al. 2011 [6] and 2019 [8]; for further explanations see text)](https://www.zkg.de/imgs/1/7/1/1/1/1/3/tok_a2a7d9147a478f1e6979176ed3d78a7d/w300_h200_x600_y343_Application_Zurbriggen_Extended_Open_Time_Figure2-33a58ab977faa6c5.jpeg)