FLSmidth helps lift white cement production in Saudi Arabia

In different regions around the world, the demand for white cement is growing. Emerging economies in particular are driving demand as construction activities increase, according to a 2018 Mordor Intelligence report, “Global White Cement Market”.

White cement is especially sought-after in countries with relatively hot climates, as it tends to help keep buildings cooler with its reflective characteristics. In addition, as a high-quality, value-added product, white cement is often used in the construction of innovative buildings and important landmarks.

It is no surprise, then, that many cement producers are seeing that the time is right to increase their white cement production capacity.

Leading track record

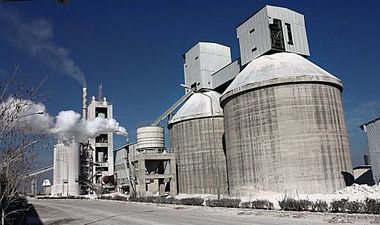

One such producer is Saudi Arabia-based Alsafwa Cement Company, which has recently awarded FLSmidth a contract to convert one of its grey cement kiln lines. This will involve the cost-effective modification of existing equipment to create a dual white and grey cement production facility.

The flexibility to adapt to market demands is a crucial competitive factor, and the new production capability will allow Alsafwa Cement Company to convert easily between grey or white cement production as necessary.

FLSmidth brings significant experience and know-how to this project, having conducted several similar grey-to-white conversions in recent years, including for the Riyadh Cement Company in Saudi Arabia and Adana Cement in Turkey.

Meeting commercial objectives

With the modified kiln expected to be commissioned in early 2020, the production objectives are to produce a minimum of 2000 t/d white clinker with a maximum heat consumption of 1380 kcal/kg clinker.

FLSmidth’s Duoflex Burner is a central element in white cement production, and the conversion project involves installing this burner inside the kiln.

Helping to keep costs to a minimum, only minor changes will be made to the current preheater with as much existing equipment as possible being reused. In this case, the oil handling equipment, clinker cooler, raw material storage system and raw mill grinding equipment will be reused.

//www.flsmidth.com" target="_blank" >www.flsmidth.com:www.flsmidth.com