Feeders for the cement industry

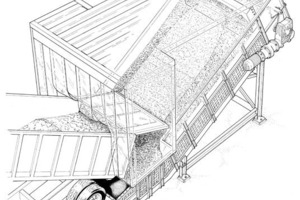

With the manufacturing base now located at the group headquarters in Germany, all B &W products benefit from the renowned AUMUND quality standards supported by experience in bulk material handling. The SAMSONTM Surface Feeder from B&W (Fig. 1), for example, receives bulk material direct from tipping trucks providing a buffer holding capacity and a controlled rate discharge eliminating the need for expensive underground pits and hoppers (Fig. 2). Using the wide Apron-Belt principle the SAMSONTM is the ideal solution for handling virtually any bulk material from dry and dusty powders through to heavy mineral ores and even wet sticky sludge without the risk of bridging or blockage, guaranteeing a reliable discharge under all conditions. Since material is received from the truck body in a controlled stream with minimum free fall, particulate separation is significantly reduced compared to traditional deep hoppers and therefore dust generation is similarly reduced often eliminating the need for extraction systems to protect the environment and thus reducing costs. Surface installation reduces project costs, improves accessibility and provides maximum flexibility in plant location with the added benefit of easy future relocation should plant developments demand this.

During past months, B &W have received several orders for the delivery of SAMSONTM Feeders to the worldwide cement industry. Titan Cement Company placed an order for one SAMSONTM (1600 x 11 m long) for handling pozzolan, gypsum, limestone and slag with a capacity up to 300 t/h at their Zlatna Panega cement mill in Bulgaria. Via AUMUND Beijing and CBMI, China, two SAMSONTM units will be supplied to the Holcim Tanga Grinding Plant in Tanzania. One machine will be used for handling clinker at 250 t/h, the other one will be used for handling additives at 100 t/h. Elite Cementos (Spain) ordered one SAMSONTM to handle clinker, gypsum and limestone at 750 t/h. One further SAMSONTM for the handling of slag, coke and coal (40 t/h) will be delivered

to Monarch Cement via the AUMUND Corporation, USA. CEMEX in Latvia placed an order with B &W for one SAMSONTM to be installed at their Broceni plant. The machine will be used to transport coal at 75 t/h. CEMEX Spain ordered a SAMSONTM to handle alternative fuels at 70 m3/h. Four identical SAMSONTM units will be supplied to Volyn Cement and YugCement (Ukraine). Once in operation the machines will handle coal at a rate of 200 t/h. A further SAMSONTM will be supplied via AUMUND Fördertechnik to the CRH Podilsky plant in the Ukraine.

www.aumund.de