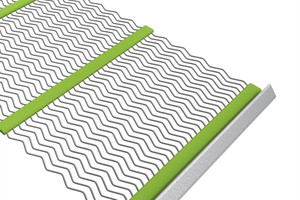

Flex-Mat High Vibration Wire Screen gives up to 40 % more throughput

Flex-Mat High Vibration Wire Screens set the standard in lowering cost of production per ton by dramatically increasing throughput and wear life while eliminating blinding and pegging. Their distinctive lime-green polyurethane strips bond independent Optimumwire wires – the industry’s longest-lasting – which vibrate at high frequency to accelerate the stratification process. The impact of the material excites the individual wires which vibrate along their entire length. The bulk material is loosened, and performance increases, maintaining screening precision.

Flex-Mat High Vibration Wire Screens are available in Optimumwire or stainless steel for ultra-fine products with a cut size of up to 0.5 mm as well as for coarser materials with cut sizes of up to 100 mm. They can be used on end- and side-tensioned screening machines and on all common modular screen decks. The polyurethane strips are custom-placed to match the position of the cross bar in the customer’s machine.

Optimumwire is a patented steel wire with an optimum content of carbon and manganese providing a superior hardness, tensile strength and ductility. Hence the resistance against abrasion and breakage under stress is significantly increased.

Due to their good wear properties, Flex-Mat screen panels can be made with thinner wires than woven wire mesh. This increases the open screening surface and at the same time capacity and productivity, often up to 40 %.

Flex-Mat and Optimumwire are manufactured by Major, a Haver & Boecker Company. Its high production capacity ensures fast delivery all over the world. The worldwide dealer network of Major offers superior service and helps producers to increase production capacity and product quality.

//www.haverboecker.com" target="_blank" >www.haverboecker.com:www.haverboecker.com

//www.majorflexmat.com" target="_blank" >www.majorflexmat.com:www.majorflexmat.com