Frugal innovations – Creating high-quality products with limited resources

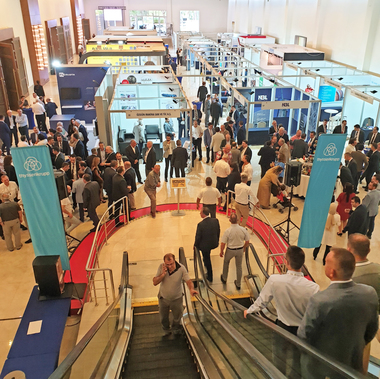

Frugal innovations were the key theme at the 14th TÇMB International Technical Seminar and Exhibition, focus topics such as alternative fuel and raw materials, energy optimization and renewable energy were addressed. More than 500 attendees met in Antalya/Turkey from 10.10.-12.10.2017 to hear news from the cement industry. At the supporting exhibition, over 100 exhibitors presented their products and services for the cement industry and informed the attendees about current projects.

In his welcome address, M. Sefik Tüzün, Chairman of the Board, Turkish Cement Manufacturers’ Association, stressed that the Turkish cement industry, as the largest cement producer in Europe and fourth largest worldwide, plays an important role in sustainability. It was important to use resources correctly and employ these sensibly so as to consume fewer raw materials, be this from an energy- or material-specific perspective. He underpinned the claim of the biennially held event to disseminate knowledge on the technology of cement production. One core point of the event was to bring together the Turkish cement producers and the suppliers on this one platform. Tüzün: “Under this main theme, 20 technical presentations will take place on many subjects related to this sector, while considering the topics of Alternative Fuel and Raw Material Use, Energy Optimization and Renewable Energy Usage as sub-topics at this year’s TÇMB International Technical Seminar and Exhibition. Our main goal is to share in that which will support global environmental protection.”

Following positive outlooks for the cement industries in India and Russia, Guiseppe Schlitzer, Italian Association of Cement Manufacturers, reported on the difficult situation of the Italian cement industry. A steadily decreasing consumption of cement over the last ten years had had a 1:1 impact on production (2006: 47880 million t, 2016: 19324 million t = -59.6 %). After these ten years of dramatic downsizing of the market, the industry was now hoping for a turnaround. Whereas there was still a total of 91 grinding and full plants in 2006, by 2016 this figure had shrunk to just 62. 26 kilns had been shut down in the last ten years. Schlitzer then summed up, projecting more “shadow than light” for the Italian cement industry.

In the subsequent company presentations and papers of the two-day programme a wide range of topics was addressed: alternative fuel, waste heat recovery, refractory linings, chemical additives, energy-saving grinding technologies, service and maintenance, optimized use of energy, NOx reduction and many more.

Joshua Detellis, GCP Applied Technologies, reported on “High performance VRMs with additives: Operational benefits and pre-hydration control.” In 2014, GCP conducted a case study with 181 different cements and established that 19 % of the ball mill cements and 48 % of the VRM cements have a high pre-hydration. Water is injected into the mills to control milling bed vibration. VRM process additives improve milling bed stability and a more stable milling bed requires less water for stable operation. On the basis of several case studies, he explained how for different mills with the addition of additives, less water must be added, leading to a decrease in prehydration and an increase in early and late strength.

Norbert Streit, KHD Humboldt Wedag, spoke on “A frugal solution for NOx reduction with KHD’s new innovation Pyroredox”. As there are different limits for NOx worldwide, various possibilities for NOx reduction are feasible, depending on the respective limit. These include low NOx burner, low NOx calciner, Pyroredox equipment as well as SNCR and SCR systems. In the Pyroredox technology for NOx-reduction, a gasifying reactor is installed between kiln and calciner. This technology is suitable for all types of typical calciner fuels.

Henrik van Deurs, FLSmidth, reported on an “Introduction to newly launched FLSmidth Jetflex burner”. Its features are rectangular rotatable jet air nozzles; straight, uninterrupted solid fuel flow, increase swivel and retractable centre pipe. The Jetflex Plus burner is suitable for use with alternative fuels. Its advantages include maximized fuel flexibility, superior combustion of lower grade fuels and a fill flame forming control.

The subject addressed by Frank O. Branvoll, Cembureau, was “Energy markets, status and forecasts with focus on solid fuels coal and petcoke”. He outlined the influence of various factors on pricing, e.g. the drastic reduction of exports from Venezuela and the impact of the recent hurricanes. For 2018, Cembureau is expecting an estimated average of $ 80 for coal and $ 65–75 for petcoke.

Michael Enders, thyssentrupp Industrial Solutions, informed attendees about the company’s Polab systems in his talk: “How quality and cost correlate: The commercial benefits from state-of-the-art lab automation systems?” He explained the advantages such as increasing automation and functionality and decreasing human error. For the modular Polab 1-3, the degree of automation increases up to fully automatic operation (sample transport, reception/handling, preparation, transport to XRF/XRD). High-end laboratory equipment costs money, but is also worth it!

Dr. Volker Wagner, Calderys, explained “Energy saving with optimized lining concepts”. He began by showing the structure of a traditional lining. With the use of alternative fuels, new challenges must be overcome: sticking problems, infiltration, corrosion of refractory materials and metallic anchors and so on. Calderys has developed a new lining concept that boasts the following properties: good alkali resistance, high mechanical strength and low thermal conductivity. First trials in German cement plants have shown excellent performance of the materials in use since spring 2014.

The support exhibition was well-frequented. The attendees took the opportunity to discuss the papers presented and talk about new projects. The industry meeting perfectly organized by the Turkish Cement Manufacturers’ Association, naturally, provided ample opportunity for the colleagues to share ideas and discuss experience with each other, for example at the closing gala dinner. The 15th TÇMB is scheduled for 2019.

//www.tcma.org.tr" target="_blank" >www.tcma.org.tr:www.tcma.org.tr