High-temperature-resistant concrete with iron mill slags

Concrete components for many industrial processes, for example in steel or cement production, are exposed to the highest stresses. These include permanent or recurring extreme temperatures of up to over 1000 °C and positive properties in the event of fire. Concretes with cement containing granulated blast furnace slag and unground granulated blast furnace slag as aggregates meet these requirements. They are characterized by high hot and residual compressive strengths, cycle stability, low thermal diffusivity and high residual load-bearing capacity. This is the result of a research project carried out by the FEhS Institute for Building Materials Research in Duisburg in close cooperation with the Chair of Materials in Construction at the University of Wuppertal.

The two responsible research managers at the FEhS Institute, Dr.-Ing. Andreas Ehrenberg and Dr.-Ing. Volkert Feldrappe: “Decades ago, work carried out by the FEhS Institute was already able to prove the positive temperature properties of blast furnace slag as an aggregate in concrete. Now we have also succeeded in using blast furnace slag and steel mill slag to help make concrete fit for high temperatures.”

Thomas Reiche, Managing Director of the FEhS Institute: “The research project once again impressively confirms the high quality of industrial by-products from the steel industry. The reliable use in special concretes and the generally excellent suitability in fire protection once again underline the enormous benefit of iron and steel slags for the economy. In addition, it can reduce the use of natural aggregates in concrete and thus make an important contribution to resource conservation.”

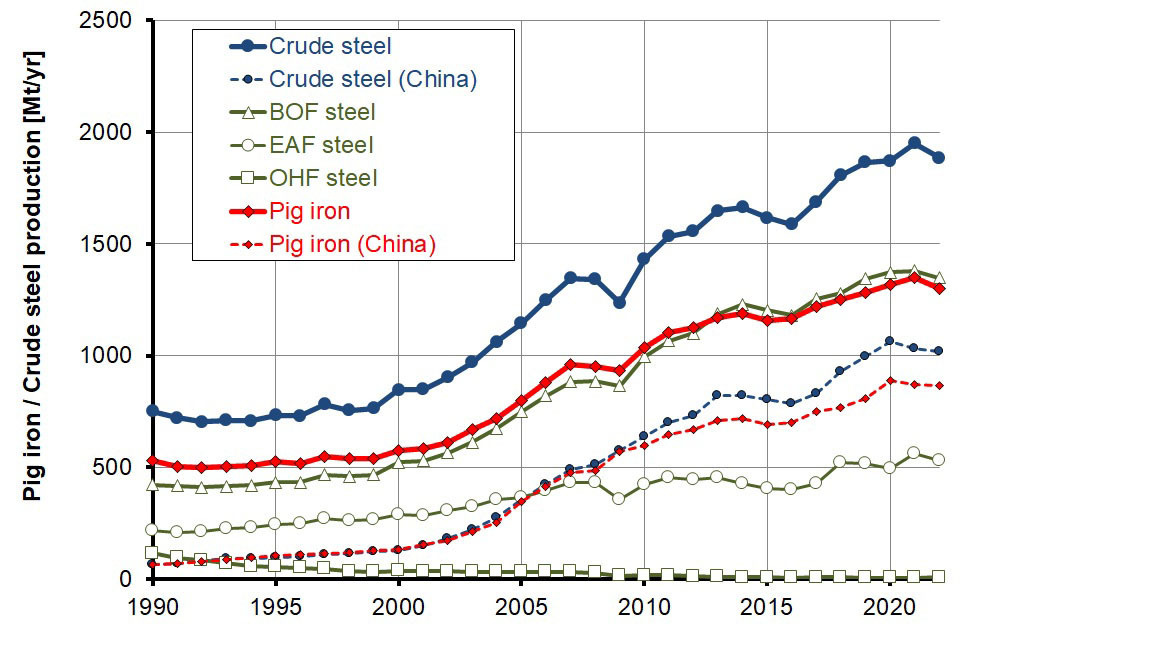

The production of pig iron and steel in Germany produces around 12.5 million t of iron mill slag every year. Depending on the metallurgical process, a distinction is made between steel mill slags and blast furnace slags, which in turn are processed into blast furnace slag and slag sand.