Holcim and Cool Planet Technologies to develop Carbon Capture Plant in Germany

Cool Planet Technologies Limited (CPT), a sustainable technology company focussed on affordable CO2 capture, and its partner Helmholtz-Zentrum hereon GmbH have signed a Memorandum of Understanding (MoU) with Holcim Deutschland GmbH to build a CO2 capture plant at Holcim’s Höver cement works, near Hannover, based on Hereon’s PolyActive™ membrane technology.

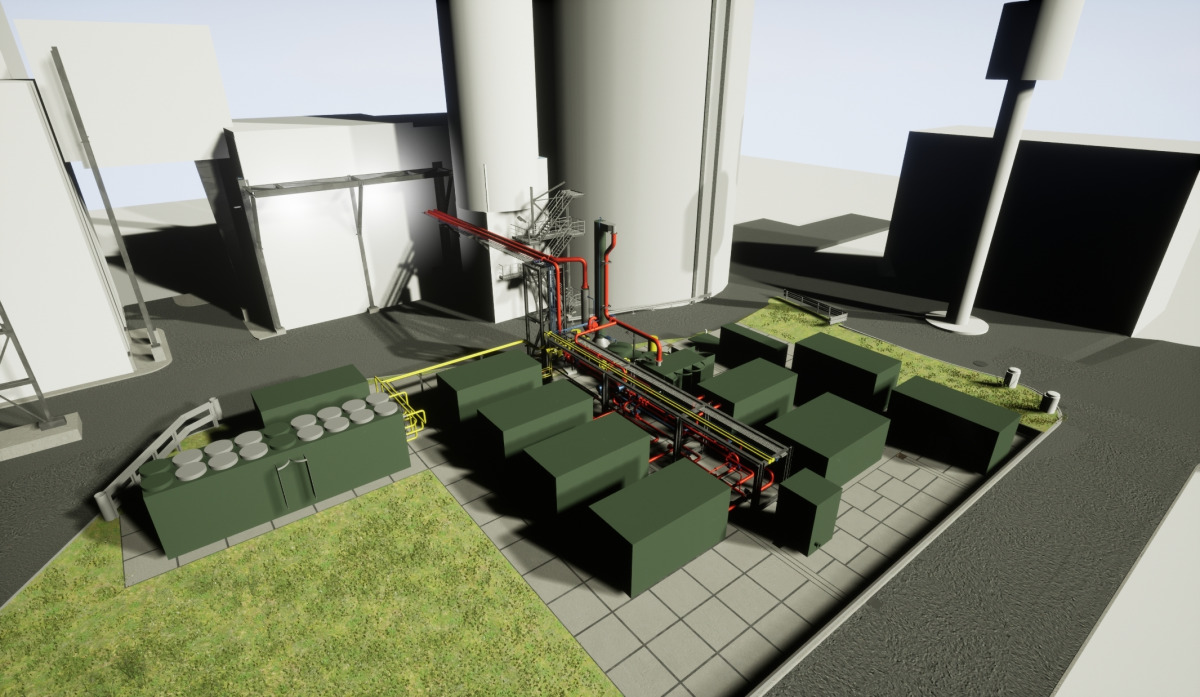

The objective of the plant is to demonstrate the performance, economics, and operability of the capture technology at scale. Following this the partners will seek to establish a framework for the technology’s implementation in Holcim’s further cement plants in Germany. Initial tests are scheduled to commence in Q1 of 2022 with the first phase of the project, capturing 5600 t/a of CO2, scheduled for start-up in Q2 2023. If successful, it is planned to expand the plant in two further phases capturing 170000 t/a and 1.3 million t/a starting-up in 2024 and 2026 respectively. The final phase will capture over 90% of the carbon dioxide emissions from the Höver plant and deliver the CO2 in high-purity liquid form for use or sequestration.

CPT is working with Hereon, part of the Helmholtz Association of Research Centres, one of Germany’s largest research organisations, to commercialise their PolyActive membrane technology after a decade of development. This technology is designed to capture CO2 from carbon rich gas streams and has already been technically proven in the laboratory and piloted in two coal-fired power stations.

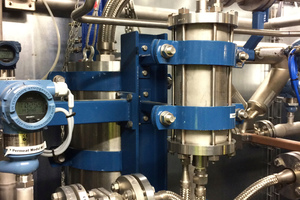

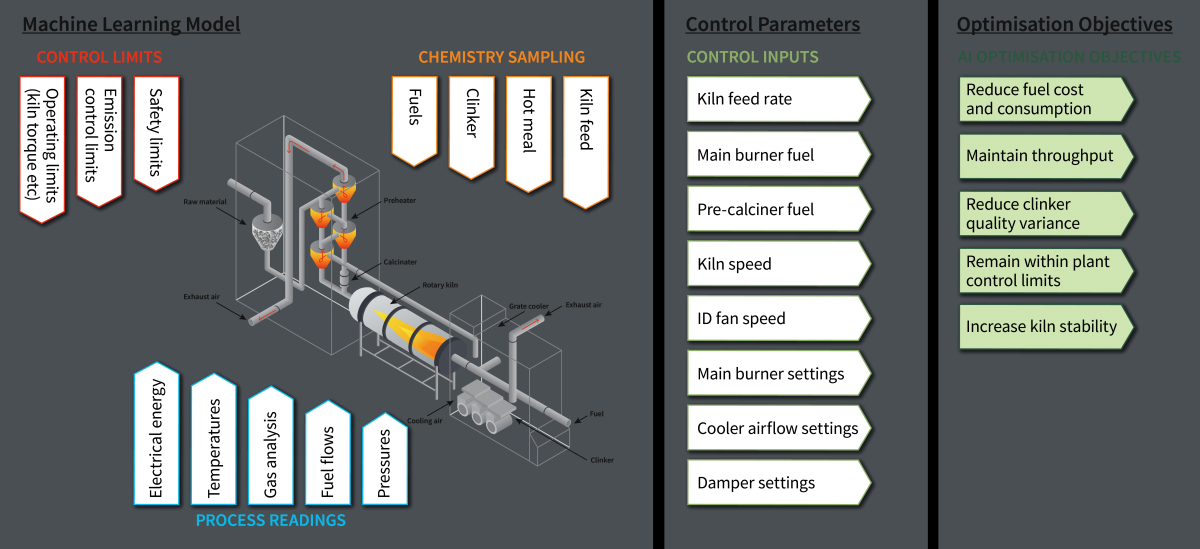

Membrane technology works by using a selective barrier material that allows the passage of CO2 in preference to the other gases. Compared with other carbon capture processes, the plant is compact, uses significantly less energy and being passive, does not require consumable chemicals for its operation. The membrane technology can be installed and operated at a low cost, giving it a substantial commercial advantage, and can be easily scaled to suit any application. This technology is an ideal retrofit (or “end of pipe”) solution for existing plants or for installation as part of a new-build plant. The technology can also be quickly started up and shut down and has excellent turndown, providing a high degree of operational flexibility.

Hereon’s membrane technology will be at the heart of the process at Höver which also uses standard proven technology from the petrochemical and cryogenic industries, CPT will be the developer, operator, and owner in the carbon capture sector, working with high industrial carbon emitters in Europe and globally to deliver affordable low-cost capture solutions.

Andrew Corner, Managing Director for CPT, said: “We are delighted to be working with Holcim and helping them to reduce their carbon emissions. Cement will remain an important building material for centuries to come so decarbonising its manufacture is a key part of achieving Net Zero. The technology being provided by CPT and Hereon will capture more than 90% of CO2 emitted at Höver. CPT is committed to bringing affordable decarbonisation solutions to industries and sectors that historically have been hard to decarbonise. We believe that our technology will significantly reduce the cost of capture and help to accelerate the adoption of commercial carbon capture.”

Torsten Brinkmann, Head of Department of Process Engineering of Hereon’s Institute of Membrane Research for Helmholtz-Zentrum hereon GmbH, said: “Membrane technology is ideally suited to address the pressing issues posed by climate change and the change in industrial feedstocks expected in the coming years. It allows for the treatment of gas streams employing an easy to use and energy efficient separation technology. The separation of CO2 from various gas streams has been a focus of Hereon’s research in recent years. The membrane, membrane module and process technologies developed by an interdisciplinary research team has been successfully tested in pilot studies in the energy industry and is ready for the next step towards decarbonising industry in collaboration with Holcim and CPT.”

Arne Stecher, Head of Decarbonization for Holcim Deutschland GmbH, said: “Carbon capture will be a must for cement plants in the near future. That is why we are searching for the best carbon capture technology. ‘Best’ for us means: simple, scalable and adaptable in many cement plants; whilst having the lowest production costs to support subsequent utilisation supply chains. The membrane approach of Cool Planet Technologies is a promising solution, therefore we and our partners are on the way to improve the level of technical readiness dramatically.”