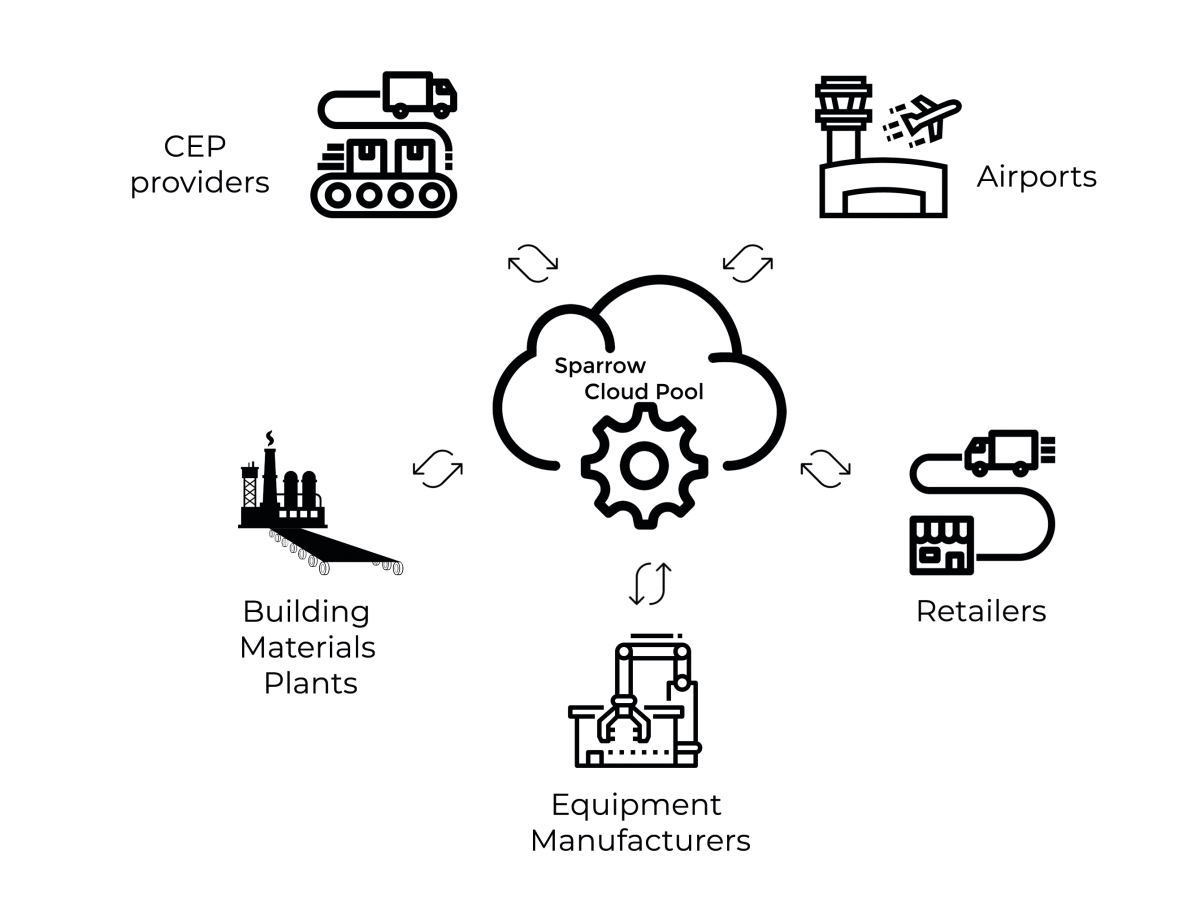

How supply chain management will change in the coming years

Change determines the general conditions. Due to the constant change in supply chain management, decision-makers need to constantly question their own situation – and find out which path to take.

Trends have always been part of the different markets of the economy. Such comprehensive changes also have a considerable impact on the value chains of companies. For this reason, decision-makers are constantly on the lookout for solutions and tools that will help them improve their own position. After all, one of the biggest challenges for companies is the increasing competition. “In addition, many companies still have problems with the automation of processes or digitalization in general. Besides short delivery times and customizability, digitalization in particular is one of the most important pillars of success,” says Rainer Schulz, warehouse automation expert and Managing Director of sysmat GmbH. Due to the constant change in supply chain management, decision-makers need to constantly question their own situation – and find out which path to take.

From changes in mobility to connectivity

There are many indications that different processes within the value chain will run largely autonomously in the future - and will continue to do so until 2040. In combination with trends such as individualization, connectivity or digitalization, urbanization, globalization or changes in mobility, a comprehensive change in supply chain management is imminent [1]. “For humans, this means that they will increasingly assume the role of supervisor and planner. New requirements in connection with flexibility also mean that adjustments must be made quickly,” says Schulz. “The decisive factor here is: Which solution helps to optimize processes and thus improve the material flow? Which one supports people particularly efficiently? The starting point is the company‘s own warehouse, this is where companies lay the foundation for success.” For example, target-oriented intralogistics reduce overall throughput times from order receipt to delivery. In the search for a suitable solution, companies can no longer avoid digital tools.

Fear of complexity

Open questions about the integration of new technologies and increasing customer requirements: two hurdles that still seem too high for some companies. Nearly half of the companies see difficulties in introducing software, implementing new functions along the supply chain, and in terms of time and cost. As a result, 91% of companies are unable to keep up with the complexities of logistics [2]. “For these reasons, the installation of a new solution depends above all on professional competence,” warns Schulz, who has developed a graphical material flow computer in the form of sysmat. “If, for example, the software to be integrated has flexible interfaces, stand-alone machines from different manufacturers can be combined into a complete system.” However, if you act hastily during implementation, you could even jeopardize the very existence of your company. “Decision-makers should therefore by no means forego an extensive test phase,” concludes Schulz.