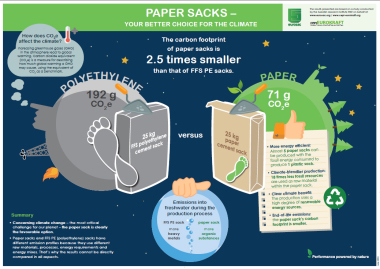

Impressive environmental balance for paper bags

The European paper bag and bag paper industry improved its CO2 footprint significantly between 2007 and 2012. This is the conclusion of a study performed by Sweden’s Innventia research institute, which regularly analyses the CO2 balance of the European paper bag production industry’s supply chain on behalf of Eurosac and CEPI Eurokraft.

From 2007 to 2012, the carbon intensity for the production of one tonne of average European Kraft paper improved from 17 %, from 570 kg CO2 equivalent (CO2e, i.e. climate-relevant gases such as carbon dioxide and methane) to 471 kg CO2e. Emissions from Kraft-paper production account for 60 % of the CO2 footprint of every paper bag produced. Along the entire production route “cradle to gate” (i.e., from the forest to the finished bag), the CO2 emissions for a single paper bag have been reduced from 118 g CO2e to 99 g CO2e, equivalent to a 16 % improvement as a result, among other factors, of a decrease in the weight of each individual bag, thanks to improved paper quality.

This convincing eco-balance is the fruit of the European bag paper and paper bag industry’s unceasing efforts to steadily cut its greenhouse gas emissions, improve energy-efficiency and increase the proportion of the renewable energy it uses - in fact, this optimisation process is proceeding significantly more rapidly than would be necessary for the attainment of the European Union’s Plan of Action on Climate Change targets for 2020.

The most important orientational data for the environmental balance is summarised in an information graphic which can be downloaded in English from the CEPI Eurokraft and Eurosac websites:

//www.eurosac.org" target="_blank" >www.eurosac.org:www.eurosac.org

//www.cepi-eurokraft.org" target="_blank" >www.cepi-eurokraft.org:www.cepi-eurokraft.org