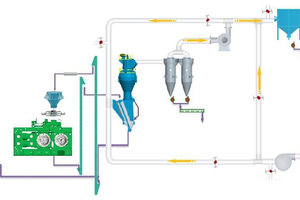

Industrial application of large raw material roller press finish grinding system

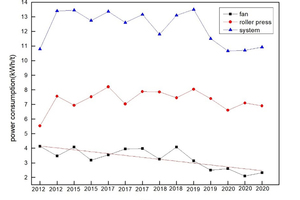

This paper introduces the large raw material roller press finish grinding system developed by Tianjin Cement Industry Design & Research Institute Ltd, which adopts newly developed equipment and process technology, such as the large raw meal roller press, new combined separator, low-resistance and high-efficiency cyclone, high-efficiency fan, and intelligent control technology. Industrial application shows that the optimal power consumption of the large raw material roller press final grinding system is only 9.1 kWh/t, and the average power consumption is 12.0 kWh/t. Compared with the other roller press systems, it has obvious power saving advantages.

1 R&D background

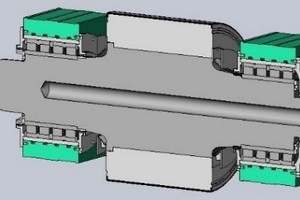

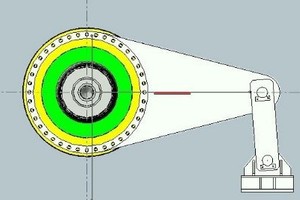

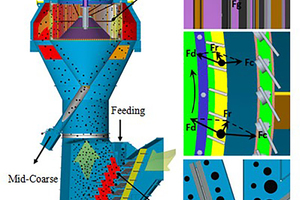

In the 1980s, TCDRI began to engage in the research and development of roller presses. After 30 years of hard work, TCDRI has always been at the forefront of technological innovation, leading the development of domestic roller press process technology and equipment. Nowadays, in addition to being used for traditional cement raw materials and cement, roller presses are also used for grinding materials such as slag, steel slag, and iron ore. In 2004, the first domestic cement roller press combined grinding system was put into operation. In 2013, the domestic largest roller press...