The cement factory proprietors of Südbayerische Portland-Zementwerke Gebr. Wiesböck & Co. GmbH have for many decades fully embraced their social, ecological and economical responsibilities. Continuous modernization and upgrading projects have safeguarded production at the factory location in Rohrdorf (Fig. 1). The company’s latest projects are an SCR system and a waste heat recovery system [1, 2]. These were reason enough for ZKG INTERNATIONAL to present an overview of the whole factory.

History

The factory was established in 1930 as the family business of the Wiesböck brothers. Originally, the company quarried natural stone, but it later changed over to the production of cement. Despite initial scepticism, this business became more and more profitable. The commencement of an economic upswing made the situation more difficult, as a number of competing factories were set up in the surrounding area. At that time, a production limit of 6000 tpy was imposed on the factory. Despite this restriction, and with a generous interpretation of the imposed limit, business developed positively, so that the company participated actively in the years of the German‚ ‘economic miracle’. This was followed by a period of diversification, and the raising of the Iron Curtain prompted a great trend for economic engagement in Eastern Germany. In addition to the factory in Bavaria, the company now operates a grinding plant in Eiberg near Kufstein and a cement works in Gmunden/Austria. When Austria joined the EU the factory started supplying the Austrian region, i.e. the company served the entire surrounding market. The Rohrdorf Group presently has a turnover of around 250 million €, generated by five fields of activity: cement, ready mixed concrete, sand and gravel, concrete products and precast elements. On the cement sector the company operates two cement factories with clinker production and one grinding plant, two mixing plants in Gmunden and Rohrdorf for special products and 11 quarries. It also has a major shareholding in a recycling company manufacturing alternative fuels. More than 1000 people work for the group.

Corporate philosophy

“Everything we do, we do a little sooner” said Heinrich Rodlmayr, the company manager responsible for technology. “Innovation has always been a central aspect of our corporate philosophy”, he added. For example: the factory was one of the very first to install a X-ray fluorescence system for raw material analysis. Rohrdorf also pioneered the usage of alternative fuel and raw materials, such as no longer recyclable foundry sand (Fig. 2) and waste products from Tetra Pak recycling. This strategy helps to ensure long-term production at the various Rohrdorf Group locations and to safeguard jobs.

The production line

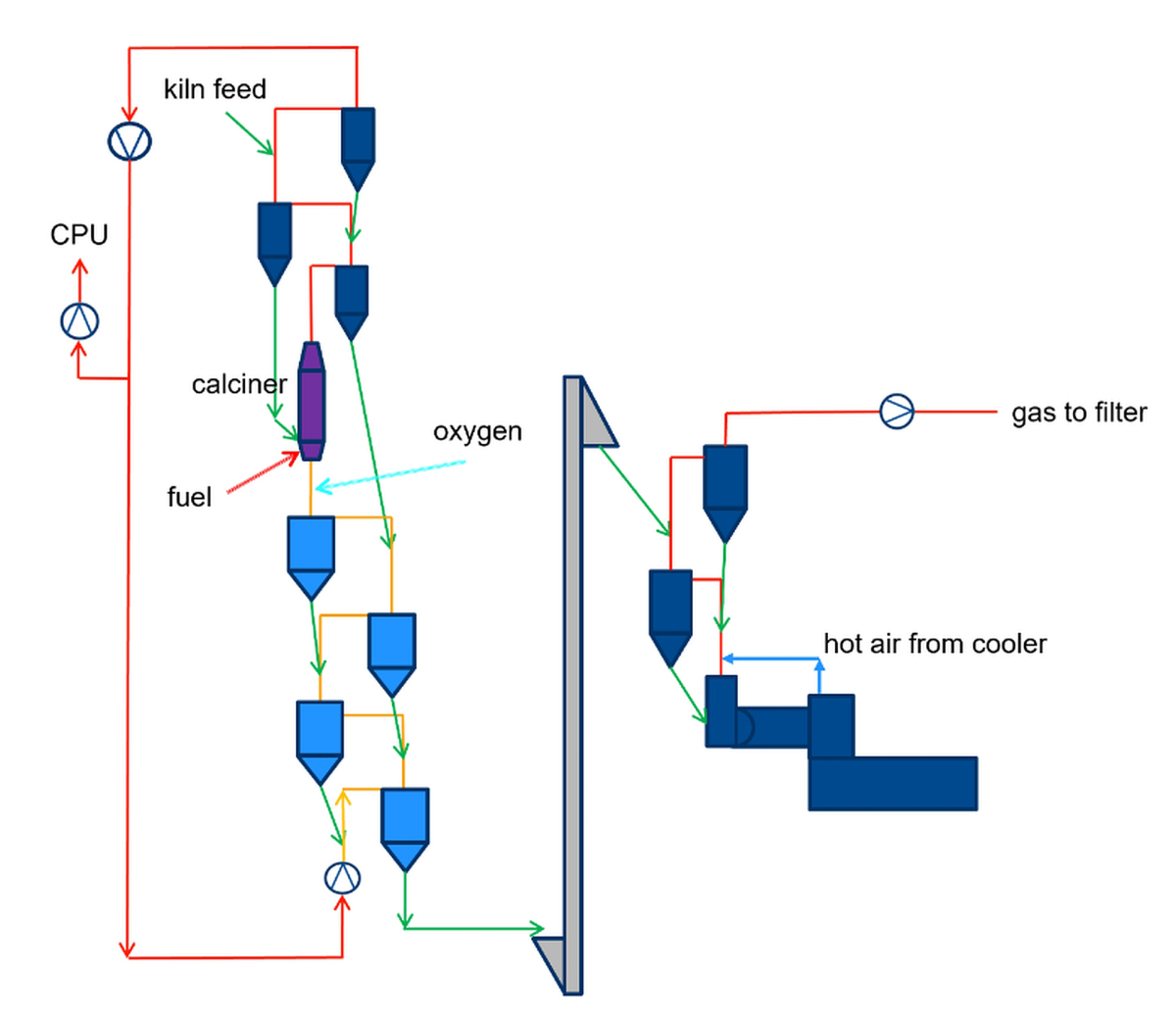

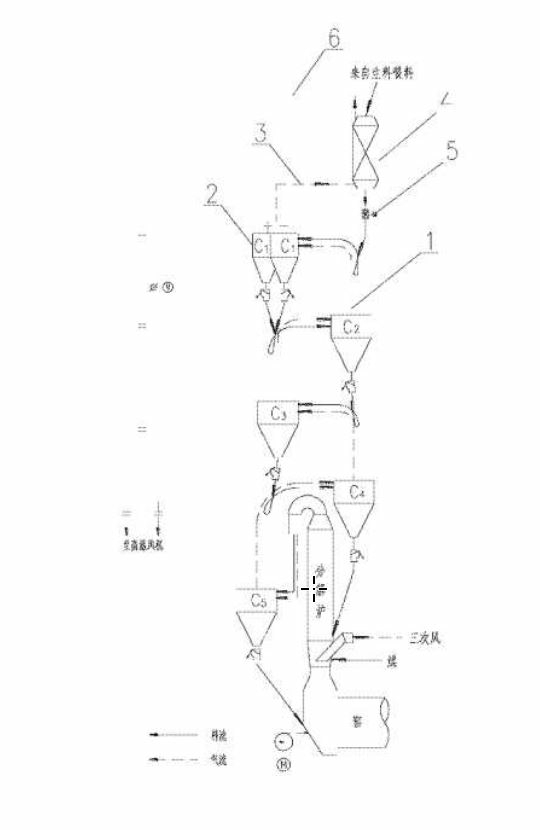

The raw materials are transported from the quarries to the factories by railway or truck (Eiberg Plant). The company possesses concessions for the next 127 years, so there is no reason to doubt raw material availability. However, transportation of the materials from some of the more distant quarries is quite expensive, making it necessary to achieve savings in other areas, e.g. energy costs. The raw material is fed into a crusher and then transported to a blending bed. Raw material grinding is performed by a Quadropol vertical roller mill (260 t/h), after which the raw meal is supplied to a DOPOL preheater (Fig. 3). The raw mill was put into operation in 2006, replacing the original ball mill that represented a bottleneck in the production process. This modernization measure increased the plant’s capacity from 3000 to 3500 tpd. In addition, the kiln inlet zone and the upper cyclone stage were modified and a new kiln exhaust gas fan was installed. At the same time, the electrostatic precipitator serving the plant was replaced with a combined bag filter for the kiln and raw mill.

Alternative fuels and raw materials

The employed alternative fuel (Fig. 4) is a mixture of shredded tyres and roofing felt, which is supplied to the preheater. In addition, paper rejects are burnt in the kiln inlet zone. The alternative raw materials fed to the kiln inlet are foundry sands and a special lime, which is a waste product of the calcium cyanamide (lime-nitrogen) production process and also contains ammonia. The special lime has an effect like a non-controlled SNCR system, which brings the disadvantage that the plant previously had a very high volatile ammonia emission. This problem has been eliminated through the installation of a new SCR system. The average annual thermal substitution rate is 77 %. The company has a permit operation with a rate of 100 %. Approximately 50 % of the alternative fuel (30 000 tpy) is production-specific commercial waste and Tetra Pak rejects, obtained from a beverage packaging recycling company.

Clinker and cement

After the burning process, the clinker can be buffer stored in three clinker silos with a total storage capacity of 120 000 t. These are followed by a POLYCOM high-pressure grinding roll for primary grinding of the clinker. The cement is ground in four cement mills, including a large ball mill (160 t/h) equipped with a ring motor. For current peak reasons, this mill is often operated at night and during the weekend. The second mill has a capacity of 60-70 t/h depending on the desired cement quality, and there are two other smaller mills with capacities of 25 t/h each. The Rohrdorf factory has positive experience with the ring-motor mill and its direct drive principle. The mill was installed in 1964, and the first inspection and maintenance of its drive was undertaken about 3-4 years ago when the outlet end wall was replaced. Otherwise, the mill is characterized by a maintenance-free operation since many years. Since then, the mill has been refurbished and a speed control function has been removed.

Constant modernization

One of the most recently implemented projects was the conversion of the clinker cooler [1] (Fig. 5). The planetary cooler was replaced with a more thermally efficient grate cooler with the installation of a waste heat recovery system. The main burner was also modernized. Hard coal is the only primary fuel and is supplied to the burner from a coal grinding system. Further alternative fuels are solvents and occasionally so called “heavy fuel”.

Waste heat recovery

Since 2012, the plant’s control loop has also included a power station (Fig. 6). A portion of the kiln exhaust gas is routed to the raw mill. However, because of the low moisture content of the raw material, only about 1/3 of the exhaust gas energy is required for drying the material.

In the past, 2/3 of the thermal energy was therefore “destroyed” by water injection in a conditioning tower and the kiln exhaust gas was cooled down to a temperature allowing supply to the downstream bag filter. Instead of the conditioning tower, the kiln exhaust gas with its temperature of approx. 430 °C is now passed through a boiler plant and the steam produced there is used for driving a turbine. The connected power generation unit produces 1/3 of the electrical power requirement of the cement factory. In addition to the boiler plant, there are two heat exchangers that recoup thermal energy from the clinker production process in order to generate electrical power. The exhaust heat power station achieves a power generation efficiency of 22 %. The power station comprises a low pressure circuit (12 bar/250 °C) and a high pressure circuit (23 bar/430 °C). Steam recooling makes use of an air-cooled condenser instead of a water cooler. This makes the factory independent of possible water shortages during dry weather periods. One advantage of the Rohrdorf works is its very dry raw material. This generally results in a very positive energy balance.Together with the exhaust gas stream from the raw mill, the kiln exhaust gas is then cleaned of residual dust and routed on to the SCR system.

Selective catalytic reduction (SCR)

After the filter fan, the kiln exhaust gas is first supplied to a plate-type heat exchanger, which heats it to approx. 230 °C (Fig. 7). A heat transfer system then raises the temperature to the 250 °C required for operation of the catalytic converter. In this system a special thermal oil is heated to approx. 260 °C in a heat exchanger installed in the mid-air extraction duct of the clinker cooler. The hot oil is pumped through a 240-m-long pipe system to the SCR system. In a second heat exchanger, the oil there heats the flue gas up to the required operating temperature of the catalytic converter. The quantity of ammonia water required for converting the nitrogen oxides in the catalytic converter is subsequently injected into the flue gas duct. Then the flue gas flows through two catalytic converter levels, in which the conversion process takes place at 250 °C. The honeycombed catalytic converter elements consist of vanadium pentoxide and tungsten trioxide with titanium dioxide as the base material. Having passed through the catalytic converter, the flue gas re-transfers its high temperature to the plate-type heat exchanger and is subsequently delivered by a the process fan to the stack with a content of < 200 mg/Nm3 NOx and without ammonia slip.

Use of synergetic effects

The SCR system and the waste heat power station were subsidized out of the environmental innovation fund of the Federal Environment Ministry. The installation of a selective noncatalytic nitrogen oxide reduction system (SNCR) would not have been practical because of the existing volatile ammonia situation resulting from the use of the special lime material. It was originally planned to install the system in the raw gas duct, but the high kiln exhaust gas temperatures of over 400 °C made this impossible. For this reason, the alternative configuration in the clean gas duct was selected in spite of the fact that this demands more energy because of the necessary re-heating of the kiln exhaust gas to the operating temperature of the catalytic converter. This necessity gave rise to the idea of utilizing the thermal energy of the mid-air of the clinker cooler for re-heating the exhaust gas in a heat transfer system. Thanks to the heat transfer system, no additional energy is required today. Rohrdorf is now the only cement factory in the world to use a SCR system in the clean gas duct. The company’s decision to implement this innovative measure was not taken lightly. It was preceded by pilot plant trials in which the interaction of the kiln atmosphere with the SCR system components was tested on a small scale. After the successful pilot phase, the industrial implementation was planned and a supplier was selected.

The Rohrdorf factory is altogether a true reflection of the corporate philosophy. In the past, today and in the future, innovation derived from tradition remains the driving force for the further development of the factory and, indeed, of the Rohrdorf Group.

www.rohrdorfer.eu