Innovative solutions from thyssenkrupp

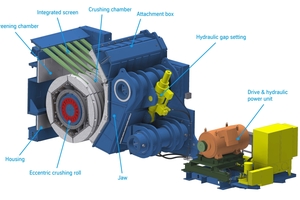

With its new eccentric roll crusher (ERC) thyssenkrupp Industrial Solutions has developed a groundbreaking solution for the primary reduction of hard rock and ore. The new crusher is particularly compact and robust. Its patented design with an integrated screen permits throughputs of up to 8000 t/h. Suitable for use both underground and in surface operations, the ERC offers significantly higher efficiency and flexibility than conventional primary crushers in the processing of hard rock.

New eccentric roll crusher (ERC) to make its world debut in Munich

The ERC is a completely new crusher type that effectively combines many advantages in one machine: Its height is 20 to 55 % lower than that of conventional primary crushers for hard rock. Despite its low height, the ERC achieves significantly higher throughputs than conventional crushers. The new series currently includes four models with capacities between 600 and 8000 t/h.

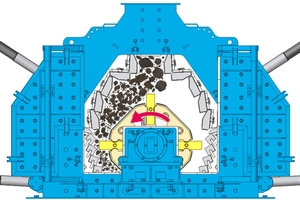

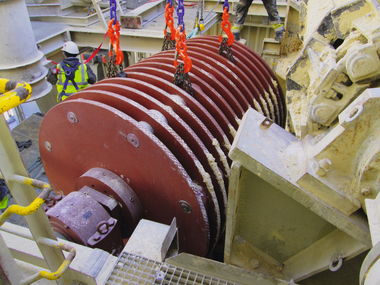

The new design with a roll mounted eccentrically between the screening and crushing chambers and the large, constant stroke of the crusher allow a very high degree of reduction. The integrated screen further increases the efficiency of the machine. Fines are not guided through the crushing chamber but discharged directly to reduce energy consumption and minimize wear to the crusher elements. An automatic crusher gap adjustment system prevents overload.

The symmetrical arrangement of the roll allows the crusher to be balanced with great precision. This significantly reduces machine vibrations and the loads on surrounding structures compared with other primary crushers. That means the ERC is also ideal for use in mobile and semi-mobile crushing systems.

variopactor: New impact crusher from thyssenkrupp

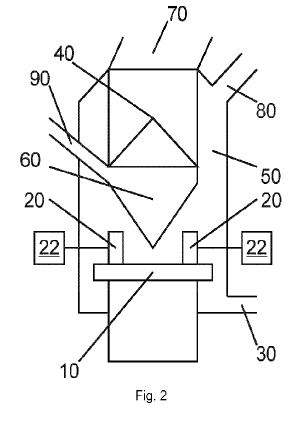

variopactor is a newly developed reversible impact crusher from thyssenkrupp Industrial Solutions. The name speaks for itself: With its modular design, the variopactor can be adapted to a wide variety of applications. In addition to its versatility, the variopactor offers consistent product quality with high cubicity and significantly reduced downtime for maintenance.

The variopactor is designed for use in small and medium-size quarries. The housing, rotor, and entire crushing chamber of the variopactor are symmetrical, so the rotor can be operated in both directions and the direction of rotation can be changed at any time. Using the rotor in both directions ensures the blow bars always operate with a sharp edge and minimizes the need to replace or turn the blow bar. The variopactor is maintenance-friendly; all wear parts are easily accessible and can be replaced quickly.

During the crushing process, the blow bars are subjected to enormous stresses. For the first time thyssenkrupp is offering the option of Metal Matrix Composite (MMC) blow bars with high-carbide inlays. Depending on application and customer requirements, the matrix material for the MMC blow bars can be made from different steel alloys. The high-carbide inlays are cast into the matrix material in the main wear zone along the edge of the blow bars, where most of the crushing work takes place. These blow bars are a new application for this material, which has been used for years to maximize the service life of hammers for hammer crushers as well as sizer and roll crusher teeth. Compared with traditional high-carbon chromium steel, it also significantly increases the service life of the blow bars.

One of the variopactor’s key strengths is its modular design. All parameters influencing the product quality, such as rotor speed and apron or grinding path position, can be flexibly adapted to the individual requirements of customers in the minerals industry. With the variopactor’s hydraulic gap adjustment system, the aprons and grinding paths can be repositioned at the push of a button so the machine can quickly be set up for different product requirements.