Laser particle sizing at the push of a button: 10 nm – 2100 µm

With the new Fritsch Laser Particle Sizer Analysette 22 NanoTec particle measurement becomes a simple matter, for professionals as well as for any employee – in production and quality control or in research and development. The advantages are: extremely simple operation, short analysis times and consistently reproducible and reliable results.

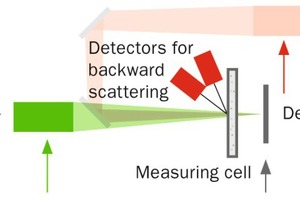

New optical design

The very large measuring range from 0.01 µm to 2100 µm of the Analysette 22 NanoTec results from the combination of two lasers with two different measuring cell detector spacings: Large particles are detected using an infrared laser with a large distance to the measuring cell, for small particles a green laser with a small distance to the cell is used, which permits the detection of the forward scattered light up to a scattering angle of 65°. The measurement of smallest particles down into the nano range is performed by the green laser light for backward scattering. Specially arranged detectors ensure this.

Intelligent modular design

The Analysette 22 NanoTec consists of a compact measuring unit that can be quickly and easily combined with different dispersion units for dry or wet measurement. Select the wet dispersion unit for wet measurements of solids and suspensions. For wet dispersion of very small quantities, the automatic small volume wet dispersion unit SVA with illuminated dispersion bath and the compact manual small volume wet dispersion unit SVM are available. The practical, fully automatic AutoSampler makes it easy to perform a series of measurements with the wet dispersion unit. For dry measurements of not too fine, free-flowing materials use the dry dispersion unit with efficient degradation of agglomerates. For dry measurement of agglomerates or free-flowing materials, choose the falling chute.

The measuring cells of the Analysette 22 dispersion modules are located in practical cartridges that can be exchanged with a single motion when switching between wet and dry measurement – without changing any hoses or modifying the instrument.

The Analysette 22 NanoTec software contains completely predefined Standard Operating Procedures – SOPs for short – for nearly all typical measurement tasks, making operation especially easy.

Perfect fully automatic evaluation

For the control, recording and perfect evaluation of the measuring results the Analysette 22 NanoTec is delivered with a computer on which the Fritsch MaS control software is already fully installed. The software MaS control is easy to learn and guides you through the entire measurement process in a largely self-explanatory manner. In addition to integrated standard reports, the freely editable report generator allows you to organise your measurement reports exactly according to your needs.