Lean manufacturing and thermal enhancement of single-layer wall with an additive manufacturing (AM) structure

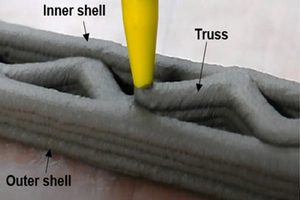

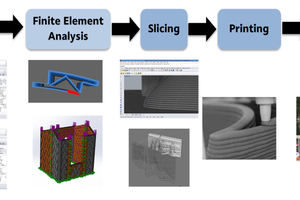

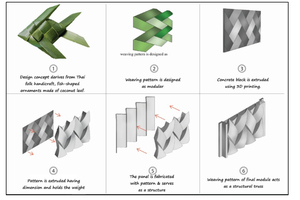

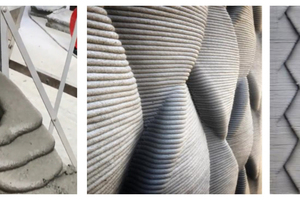

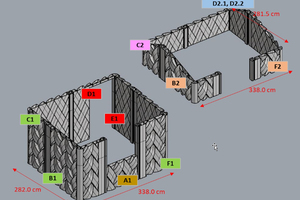

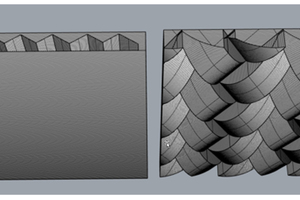

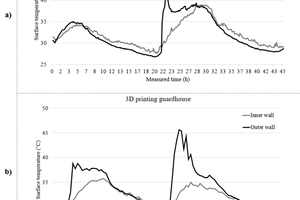

The emergence of large-scale additive manufacturing (AM) technology has been increasing around the world. This large-scale AM technology has facilitated several projects using cement-based materials. AM technology can theoretically be applied in modern construction but much work is still required for further investigation and implementation in the field of lean manufacturing practice. This work describes the AM of textured single-layer wall panels assembled to form a guardhouse structure. The innovation in this structure lies in the design of the textured single wall layer that is not generally found in existing AM textured walls. The benefit of using lean manufacture for the AM textured single wall panel is the reduction in weight; 10 to 11 % less material is required. Another benefit found in the architectural design and surface textures of the AM structure is the considerable improvement in the thermal properties and the 31 % energy saving when compared with the conventional design.

1 Introduction

For many decades the research and development programmes for large-scale additive manufacturing (AM) or 3D printing technology in such domains as design, construction, and architecture have been using various types of materials, such as plastics [1, 2], metals [3], ceramics [4], wood [5], asphalt [6] and cement-based materials [7-11]. The attention of academics, construction material producers, architects, and contractors is becoming increasingly drawn towards large-scale AM technology. Large-scale AM technology results in many benefits through the increased degree of...

![1 AM five-story building in China [28]](https://www.zkg.de/imgs/1/4/2/2/0/6/2/tok_7c14f924e80543a225290226443bda22/w300_h200_x286_y163_Application_Siam_bild1-e176c50389d3846b.jpeg)

![2 Outline of the entire house printed by a large-scale D-shaped machine [29]](https://www.zkg.de/imgs/1/4/2/2/0/6/2/tok_f7aaf97fee6c960278dc240a74a0fae9/w300_h200_x287_y226_Application_Siam_bild2a-047717f5bc8eb990.jpeg)