Low energy slag and cement production

(22) 16.09.2012

(45) 12.01.2013

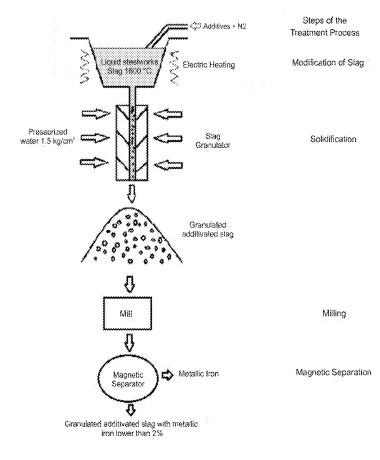

(57) A slag powder and cement production system capable of utilizing slag immediately after generation as a byproduct of a primary manufacturing process to recover thermal energy of slag concurrently with preparation of slag for cement in a powdered form to maximize energy recovery from primary manufacturing process and to minimize energy consumption to transform slag into a slag powder. Preferably the heat removed from the liquid slag as it solidifies is recovered for useful work, such as sustaining the primary manufacturing process or co-located cement production process and/or electric power production preferably through a supercritical CO2 thermodynamic cycle operating through a heat exchanger less transfer of thermal energy from the slag.

(71) Michael Gurin, Glenview, IL (US)