Method and the system for cleaning waste gases from furnaces designed for firing clinker from nitrogen, sulfur and mercury oxides

(22) 28.12.2016

(43) 02.07.2018

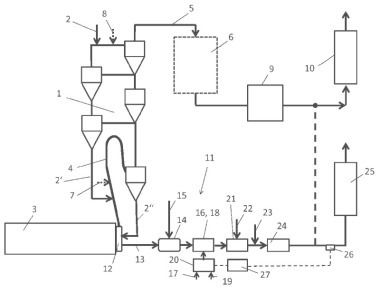

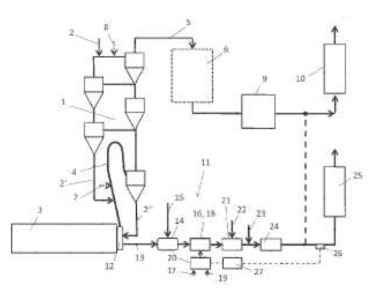

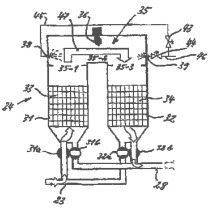

(57) The subject of the application is a method of purification of flue gases from clinker burning furnaces from nitrogen oxides, sulfur and mercury oxides, characterized by the fact that in the process of raw material milling, adequate humidity, temperature and dust levels of gases in the firing system are obtained, followed by a purification reactor gases (7) are introduced into the oxidant in the form of highly dispersed droplets – moreover, in the reactor (7) the retention of purified gases with introduced oxidant is carried out for at least 5 seconds. and an additional reduction of mercury emission from treated gases is obtained by partial or total removal of dust from filters (8) and (10) resulting from the final dusting process and returning them to the firing system as part of the raw meal and in the case of higher concentrations of mercury partially or completely removed from firing system by by-pass. The application also includes a system for the purification of flue gases from clinker burning furnaces from nitrogen, sulfur and mercury oxides, consisting of an oven (1), a cyclone heat exchanger (2), fans (3, 10) of the raw material mill (4), filters ( 9, 11), characterized in that between the mill of the raw material (4) and the final filter (9) an additional system consisting of a gas dust collector (5), a gas purification reactor (7) and a fan (8) is introduced.

(71) Instytut Ceramiki i Materiałów Budowlanych w Warszawie Oddział Inżynierii Materiałowej, Procesowej i S´rodowiska w Opolu (PL)